Automation light grids

Two-dimensional inspection or counting tasks are important in automation. SICK’s automation light grids can be used in a number of these solutions, such as detecting and counting irregularly shaped objects,

Two-dimensional inspection or counting tasks are important in automation. SICK’s automation light grids can be used in a number of these solutions, such as detecting and counting irregularly shaped objects,

people and vehicles, and checking for presence and pallet overhang detection. The tasks are so versatile that one light grid cannot fulfill the requirements of every application. Light grids from SICK offer multiple ranges, heights, sizes, orientations, and resolutions which simplify integration through high flexibility and performance.

Laser measurement technology devices can be used for a wide range of applications. These devices detect both 2D and multi-dimensional contour data and can process information either externally or in the sensor itself.

Laser measurement technology devices can be used for a wide range of applications. These devices detect both 2D and multi-dimensional contour data and can process information either externally or in the sensor itself. SICK has a wide range of optic and ultrasonic solutions that measure from sub-microns to kilometers. They solve measuring, detecting and positioning applications using triangulation and time-of-flight modes.

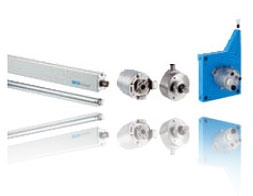

SICK has a wide range of optic and ultrasonic solutions that measure from sub-microns to kilometers. They solve measuring, detecting and positioning applications using triangulation and time-of-flight modes. Paths, position, angle – an encoder is the first choice when it comes to precise position detection in industrial automation. The same applies to revolutions and rpm, speed and acceleration.

Paths, position, angle – an encoder is the first choice when it comes to precise position detection in industrial automation. The same applies to revolutions and rpm, speed and acceleration. Blowoff, Clean,Dry and Cool with Less Noise and Air Consumption

Blowoff, Clean,Dry and Cool with Less Noise and Air Consumption Vent,Exhaust, Cool, Dry and Clean- with No Moving Parts

Vent,Exhaust, Cool, Dry and Clean- with No Moving Parts Proximity sensors provide non-contact detection of a wide variety of objects and media. SICK’s sensors are perfectly suited to industrial applications and requirements.

Proximity sensors provide non-contact detection of a wide variety of objects and media. SICK’s sensors are perfectly suited to industrial applications and requirements. SICK offers a powerful vision sensor portfolio designed to manage challenges in all industries where a standard sensor would not work. These vision sensors provide a full toolset for positioning, inspection, measurement and reading, depending on the variant. A flexible optical design fulfills the needs of almost all applications. Simplicity is ensured by automatic setup, intelligent algorithms and a common, intuitive user interface.Our product range includes all types of SICK, Rotomotive & SMC Products.

SICK offers a powerful vision sensor portfolio designed to manage challenges in all industries where a standard sensor would not work. These vision sensors provide a full toolset for positioning, inspection, measurement and reading, depending on the variant. A flexible optical design fulfills the needs of almost all applications. Simplicity is ensured by automatic setup, intelligent algorithms and a common, intuitive user interface.Our product range includes all types of SICK, Rotomotive & SMC Products.