Molecular Distillation

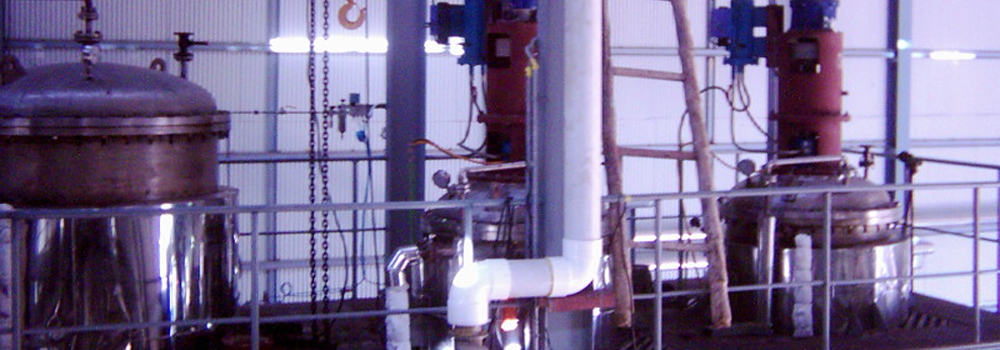

This form of still offered by us has a fast rotating spinning cone, to create a fast spreading and moving film of liquid. When the rotating cone or disc is heated, distillation takes place

Advantages :

- No thermal degradation

- Low process cost

- Higher purity

We offer lab unit, pilot scale unit and production units for the above purpose. The viscosity ranges upto 4,000 CSt(30oC), molecular weight ranges 100-5,000 and pressures upto 0.0005 torr or 0.5 micron, temperatures upto 400o C are handled in these plants.

Typical applications are, Aromatic hydrocarbons, cocoa butter, Dimer acid, epoxy resins, lubricants, micro crystalline wax, , Silicone oils, Vitamins A, E etc.

Plant Specifications

| Model | CMD-4 | CMD-15 | CMD-36 |

| Throughput-typical | 2 kg/hour | 20-25 Kg/hour | 80 Kgs/hour |

| Application | Lab studies | Pilot scale | Production |

| Heating KW(Max) | 2 | 6 | 24 |

| Pumping | Vane pump + Diffusion pump | Vane pump + D.P. | Piston+roots + D.P. |

| Nett weight | 75 Kgs | 870 Kgs | 2000 Kgs |

Degassing section is provided in the rotor itself. Heating is done through induction heating of the rotor and impedance heating of the feed. Effectiveness of separation depends on the difference in the molecular weights.