Induction Heating

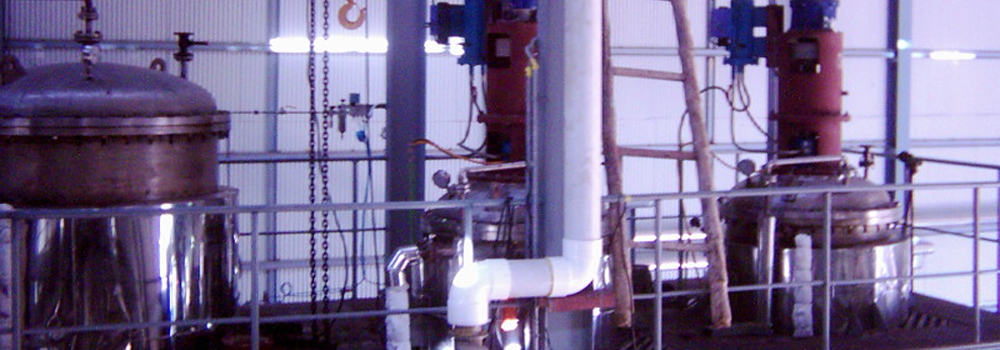

A) Induction Heating for Reactors, Distillation Vessels

Mode of heating : Alternating magnetic field in the work coil creates induced current in the work piece, causing heat.

Important parameters to be considered in the design of the induction heating.

- ⇒ Coil design

- ⇒ Generator frequency

- ⇒ Applied power density

Advantages :

- ⇒ Heat is very controllable

- ⇒ Fast cycle

- ⇒ Excellent heat transfer(heat is produced in the job itself , unlike other modes of heating like thermic fluid boiler, steam boiler etc.)

- ⇒ Induction coil does not add to the thermal mass.

- ⇒ Low maintenance

- ⇒ Highest efficiency of 95% as compared to the other methods of heating

- ⇒ Induction heating can also be used in the flame proof areas, with the required safety aspects taken into consideration.

B) Impedance Heating For The Pipe Lines, Pre-Heating The Liquids/Gases In The Pipelines/Reactors/Storage Tanks

Applications : Heating of high pressure gases,lube oil, fuel oil, chocolate, chemicals, resins and many other speciality products

Advantages :

- ⇒ Pipe line becomes the heating element. Hence no heater burnout. No jacket to the pipe line. Existing pipe line can be used, without any alterations.

- ⇒ Voltages are in the range of 5 V-30volts.Hence safe operation.

- ⇒ Since pipe line is heated, there will be good heat transfer to the materials flowing inside

- ⇒ No hot-spots. Hence ideal for heat sensitive materials

- ⇒ Precise temperature control (SCR control)

- ⇒ Highest efficiency of all modes of pipe line heating