Waste Oil Re-Refining

Technology & Process :

- ⇒ Pre-treatment of the used oil - using two natural polymers to remove carbon sludge substantially

- ⇒ High vacuum short path distillation(molecular distillation) is employed to remove 95% of the available oil

- ⇒ The distilled oil is bleached using active clay to get metals free base oil of required viscosity

- ⇒ The residue is processed for making soft asphalt, off speck fuel oil or briquetts. Hence it is a zero waste technology

Details of the plants offered

| Throughput (litres per hour) | 100 | 200 | 500 | 1000 | 2000 |

| Total power required (in KW) | 80 | 150 | 180 | 240 | 300 |

| Land (in metre2) | 500 | 1000 | 1000 | 2000 | 5000 |

| Building (in metre2) | 120 | 150 | 250 | 500 | 1000 |

| Staff/Labour | 9 | 9 | 15 | 15 | 18 |

| Pre-treatment polymer(in MT/year) | 7.2 | 14.4 | 36 | 72 | 180 |

| Base oil (KL/month) | 36 | 72 | 18 | 360 | 900 |

| Processing cost(typical) in USD/litre input | 0.05 | 0.04 | 0.03 | 0.02 | 0.02 |

| Return on total capital(typical) (in%) | 25 | 38 | 60 | 85 | 165 |

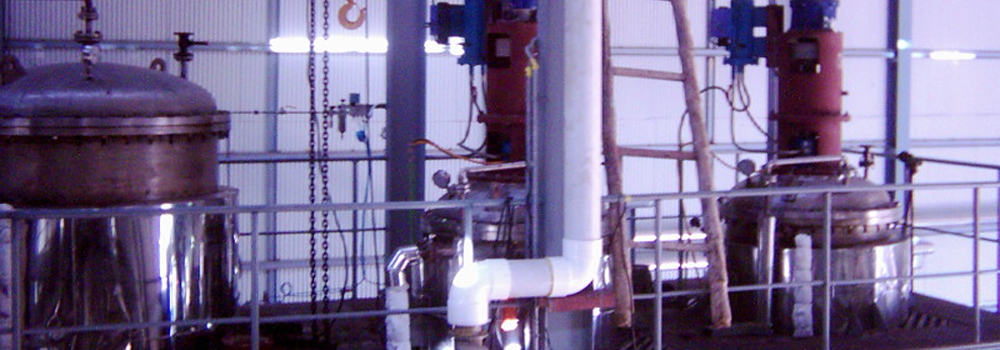

Main capital equipments involved are: Pre treatment reactor, centrifuge, pressure leaf filter, small thermic fluid heater, molecular distillation plants with accessories, vacuum pumping system (0.005mm of mercury), bleaching, filter system, blending, induction heating system, cooling tower etc.

| Quality of the processed base oil | |

| Colour, D-1500 | 1-1.5 |

| Flash Point, COC, D-92 | 240 degree C |

| Total Metals Content (FAS 2C-21) | 60-70 ppm |

| Ash Content, D-482 | 0.3% |

| Viscosity, 100 degree C, D-446 | 11-12 Cst |