Our domain expertise has enabled us to come up with Industrial Drill. Under this category, we offer our customers a wide assortment of Solid Carbide Step Drill, Solid Carbide Drill, Solid Carbide Core Drill and Solid Carbide Flat Drill. The range offered by us is appreciated in the market for its features such as resistance against corrosion and high strength. We offer these industrial drills to the clients at market-leading prices.

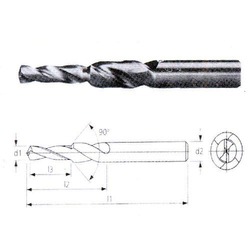

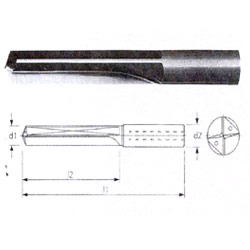

With the help of experienced engineers, we have been able to design and develop Solid Carbide Step Drill. These are designed and manufactured by the professionals in compliance with the industry standards. The offered drills are widely acknowledged for their attributes such as perfect finish, accurate dimensions, high strength and durability.

With the help of experienced engineers, we have been able to design and develop Solid Carbide Step Drill. These are designed and manufactured by the professionals in compliance with the industry standards. The offered drills are widely acknowledged for their attributes such as perfect finish, accurate dimensions, high strength and durability.

| Features: • Cylindrical shank • 4 facet • Countersink angle 90° • Point angle 120° • Right hand cutting Additional Information: • Item Code: ABT-509 |

Grade: • K10 micro-fine • P30 • TiAln/TIN coating • All dimensions are in mm Applications: • Suitable for centering holes in steel applications • Suitable for drilling tap holes with countersinks |

| Tap Size | D1 H8 | D2 H7 | l1 | l2 | l3 |

| M4 | 3,30 | 6,00 | 62 | 20 | 11,4 |

| M5 | 4,20 | 6,00 | 66 | 28 | 13,4 |

| M6 | 5,00 | 8,00 | 79 | 34 | 14,5 |

| M8 | 6,80 | 10,00 | 89 | 47 | 21,0 |

| M10 | 8,50 | 12,00 | 102 | 55 | 25,5 |

| M12 | 10,20 | 14,00 | 107 | 60 | 30,0 |

| M14 | 12,00 | 16,00 | 115 | 65 | 34,5 |

| M16 | 14,50 | 16,00 | 123 | 73 | 38,5 |

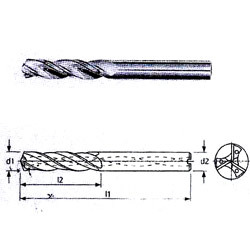

Innovation is our forte and we strive to design and develop Solid Carbide Drill. The offered carbide drills can be availed by the clients in varied sizes & technical specifications in order to meet their requirements. Owing to the dimensional accuracy, low maintenance cost and resistance against corrosion features, these are appreciated in this highly competitive market. Our professionals ensure that only defect-free range is delivered at the clients' end within the promised time.

Innovation is our forte and we strive to design and develop Solid Carbide Drill. The offered carbide drills can be availed by the clients in varied sizes & technical specifications in order to meet their requirements. Owing to the dimensional accuracy, low maintenance cost and resistance against corrosion features, these are appreciated in this highly competitive market. Our professionals ensure that only defect-free range is delivered at the clients' end within the promised time.

| Features: • Right hand cutting • Cylindrical shank • Point angle 120° • Step angle 180° • 4 facet Additional Information: • Item Code: ABT-502 |

Grade: • K10 micro-fine • P30 • TiAln/TIN coating • All dimensions are in mm Applications: • Suitable for centering holes in steel applications • Suitable for drilling tap holes with counters |

| D1 H8 | D2 H7 | l1 | l2 |

| 4,00 | 4,00 | 55 | 22 |

| 4,50 | 4,50 | 58 | 24 |

| 5,00 | 5,00 | 62 | 26 |

| 5,50 | 5,50 | 66 | 28 |

| 6,00 | 6,00 | 66 | 28 |

| 6,50 | 6,50 | 70 | 31 |

| 7,00 | 7,00 | 74 | 34 |

| 7,50 | 7,50 | 74 | 34 |

| 8,00 | 8,00 | 79 | 37 |

| 8,50 | 8,50 | 79 | 37 |

| 9,00 | 9,00 | 84 | 40 |

| 9,50 | 9,50 | 84 | 40 |

| 10,00 | 10,00 | 89 | 43 |

| 10,20 | 10,20 | 89 | 43 |

| 10,50 | 10,50 | 89 | 43 |

| 11,00 | 11,00 | 95 | 47 |

| 11,50 | 11,50 | 95 | 47 |

| 12,00 | 12,00 | 102 | 51 |

| 12,50 | 12,50 | 102 | 51 |

| 13,00 | 13,00 | 102 | 51 |

| 14,00 | 14,00 | 107 | 54 |

| 15,00 | 15,00 | 111 | 56 |

| 16,00 | 16,00 | 115 | 58 |

| 18,00 | 18,00 | 123 | 62 |

| 20,00 | 20,00 | 131 | 66 |

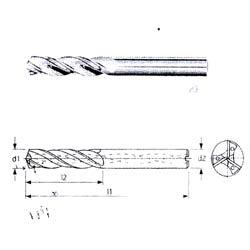

Our organization is counted among the distinguished manufacturers, suppliers and traders of Industrial Solid Carbide Drill. The offered carbide drills are widely used for steel, cast iron and exotic material drilling applications. We offer these drills to the clients in variegated sizes, shapes and diameters. Owing to the features such as low maintenance cost and resistance against corrosion, these find their applications in engineering, heavy machinery and automobile industries.

Our organization is counted among the distinguished manufacturers, suppliers and traders of Industrial Solid Carbide Drill. The offered carbide drills are widely used for steel, cast iron and exotic material drilling applications. We offer these drills to the clients in variegated sizes, shapes and diameters. Owing to the features such as low maintenance cost and resistance against corrosion, these find their applications in engineering, heavy machinery and automobile industries.

| Features: • Point angle 120° • Standard length- N type • Right hand cutting Additional Information: • Item Code: ABT-501 |

Grade: • P30 • TiA ln/ TIN coating • K10 micro-fine Applications: • Suitable for drilling heat resistant steel chilled casting, Cr-Ni steel gray casting bronze aluminum • Point geometry as per specific application or else N-type |

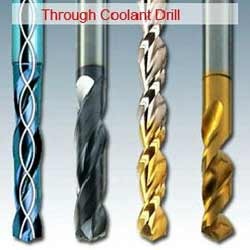

| Features: • Right hand Cutting • 3 Cutting Edges • Point Angle 140° • 4-Facet • Chisel Edge With Thinned Web • Through Coolant Holes • 3*D Additional Information: • Item Code: ABT-504 |

Grade: • K10 Micro-fine • P30 on request • TiA ln / TIN Coating - on request Applications: • Suitable for drilling in short Chipping & non-ferrous material |  |

| D1 H8 | D2 H7 | l1 | l2 |

| 6,00 | 6,00 | 93 | 57 |

| 6,50 | 6,50 | 101 | 63 |

| 7,00 | 7,00 | 109 | 69 |

| 7,50 | 7,50 | 109 | 69 |

| 8,00 | 8,00 | 117 | 75 |

| 8,50 | 8,50 | 117 | 75 |

| 9,00 | 9,00 | 125 | 81 |

| 9,50 | 9,50 | 125 | 81 |

| 10,00 | 10,00 | 133 | 87 |

| 10,50 | 10,50 | 133 | 87 |

| 11,00 | 11,00 | 142 | 94 |

| 11,50 | 11,50 | 142 | 94 |

| 12,00 | 12,00 | 151 | 101 |

| 12,50 | 12,50 | 151 | 101 |

| 13,00 | 13,00 | 151 | 101 |

| 14,00 | 14,00 | 160 | 108 |

| 15,00 | 15,00 | 169 | 114 |

| 16,00 | 16,00 | 178 | 120 |

| Features: • Cylindrical Shank • Right hand Cutting • 3 Cutting Edges • Point Angle 140° • Solid Point, 4-Facet Ground Additional Information: • Item Code: ABT-505 |

Grade: • K10 Micro-fine • P30 on request • TiA ln / TIN Coating - on request Applications: • Suitable for drilling holes on long chipping tough material |

.jpg) |

| D1 h8 | D2 H7 | l1 | l2 |

| 4,50 | 4,50 | 58 | 24 |

| 4,80 | 4,80 | 62 | 26 |

| 5,00 | 5,00 | 62 | 26 |

| 5,50 | 5,50 | 66 | 28 |

| 6,00 | 6,00 | 66 | 28 |

| 6,50 | 6,50 | 70 | 31 |

| 7,00 | 7,00 | 74 | 34 |

| 7,50 | 7,50 | 74 | 34 |

| 8,00 | 8,00 | 79 | 37 |

| 8,50 | 8,50 | 79 | 37 |

| 9,00 | 9,00 | 84 | 40 |

| 9,50 | 9,50 | 84 | 40 |

| 10,00 | 10,00 | 89 | 43 |

| 10,20 | 10,20 | 89 | 43 |

| 10,50 | 10,50 | 89 | 43 |

| 11,00 | 11,00 | 95 | 47 |

| 11,50 | 11,50 | 95 | 47 |

| 12,00 | 12,00 | 102 | 51 |

| 12,50 | 12,50 | 102 | 51 |

| 13,00 | 13,00 | 102 | 51 |

| 14,00 | 14,00 | 107 | 54 |

| 15,00 | 15,00 | 111 | 56 |

| 16,00 | 16,00 | 115 | 58 |

| 18,00 | 18,00 | 123 | 62 |

| 20,00 | 20,00 | 131 | 66 |

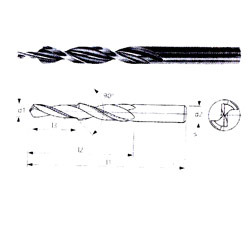

| Features: • Right Hand Cutting • Web thickness less than standard • Point Angle 120° • Up to 0 10 4 facet • Over 0 Cone Relieved Additional Information: • Item Code: ABT-507 |

Grade: • K10 Micro-fine • P30 on request • TiA ln / TIN Coating - on request Applications: • For Precise drilling on NC machines |

|

| D1 h8 | D2 H7 | l1 | l2 |

| 5,00 | 5,00 | 50 | 18 |

| 6,00 | 6,00 | 50 | 18 |

| 6,35 | 6,35 | 50 | 18 |

| 8,00 | 8,00 | 60 | 20 |

| 9,52 | 9,52 | 60 | 22 |

| 10,00 | 10,00 | 60 | 22 |

| 12,00 | 12,00 | 60 | 25 |

| 12,70 | 12,70 | 60 | 25 |

| 16,00 | 16,00 | 75 | 25 |

| 19,05 | 19,05 | 75 | 28 |

| 20,00 | 20,00 | 75 | 28 |

Features:

Features:

• Countersink Angle 90°

• Point Angle 120°

• Cylindrical Shank

• 4 facet

• Right Hand Cutting

| Tap Size | D1 H8 | D2 H7 | l1 | l2 | l3 |

| M6 | 5 | 6.6 | 101 | 63 | 16.3 |

| M8 | 6.8 | 9 | 125 | 81 | 21.0 |

| M10 | 8.5 | 11 | 142 | 94 | 25.5 |

| M12 | 10.2 | 13.5 | 160 | 108 | 30.0 |

| Features: • Straight Flutes • Through Coolant holes • Right Hand Cutting • Straight Shank to DIN 6535 HAK • Extra Long • 2 Edges Cutting • 2 Edges Burnishing • 3 x D |

Grade : • K10 Micro-fine • P30 on request • TiA ln / Tin Coating - on request Applications: • Abrasive Materials like Cast Iron Malleable Cast Iron, Aluminum, Brass, Bronze |

|

| D1 H8 | D2 H7 | l1 | l2 |

| 5,00 | 6,00 | 66 | 28 |

| 6,00 | 6,00 | 66 | 28 |

| 6,80 | 8,00 | 79 | 34 |

| 7,00 | 8,00 | 79 | 34 |

| 8,00 | 8,00 | 79 | 41 |

| 8,50 | 10,00 | 89 | 47 |

| 9,00 | 10,00 | 89 | 47 |

| 10,00 | 10,00 | 89 | 47 |

| 10,20 | 12,00 | 102 | 55 |

| 10,50 | 12,00 | 102 | 55 |

| 11,00 | 12,00 | 102 | 55 |

| 12,00 | 12,00 | 102 | 55 |

| 14,00 | 14,00 | 107 | 60 |

| 16,00 | 16,00 | 115 | 65 |

| 18,00 | 18,00 | 123 | 73 |

| 20,00 | 20,00 | 131 | 79 |

Being a quality focus organization we offer a wide array of Step Drill. Offered range caters fine production. Besides, these products are recommended by the clients for their precise performance and high tensile strength. Moreover, our range is available in various patterns and sizes that are reckoned amongst the clients for their efficiency and effectiveness. As well, our range can be customized as per specific requirements of the clients.

Being a quality focus organization we offer a wide array of Step Drill. Offered range caters fine production. Besides, these products are recommended by the clients for their precise performance and high tensile strength. Moreover, our range is available in various patterns and sizes that are reckoned amongst the clients for their efficiency and effectiveness. As well, our range can be customized as per specific requirements of the clients.

Features:

• Supreme functioning

• Available in various specifications

• Reasonable

Compact designed and light weighted Coolant Fed Drill is offered to our esteemed clients. Our range is demanded by the clients for its flawless performance. Also, offered range is reckoned amongst the clients for its sturdiness and durability. Moreover, our range is available in both generic and customized pattern in order satisfies the diverse requirements of the clients.

Compact designed and light weighted Coolant Fed Drill is offered to our esteemed clients. Our range is demanded by the clients for its flawless performance. Also, offered range is reckoned amongst the clients for its sturdiness and durability. Moreover, our range is available in both generic and customized pattern in order satisfies the diverse requirements of the clients.

Features:

• Available in various specifications

• Precise performance

• Low cost maintenance

| Feature: • Web thickness less than standard • Point Angle 120° • Upto Ø 10 4 facet • Over Ø Cone Relieved |

Grade: • K10 Microfine • P30 on request • Tia ln / Tin Coating - on request Application: • For precise drilling on NC machine. |

|