Mist Eliminator

KEVIN Mist Eliminators Effective separation of vapor and liquid is a primary requirement for efficient industrial processing. KEVIN Mist Eliminators are engineered to provide high efficiency & low pressure drop for effective separation.

Effective separation of vapor and liquid is a primary requirement for efficient industrial processing. KEVIN Mist Eliminators are engineered to provide high efficiency & low pressure drop for effective separation.

KEVIN Liquid Coalescers

KEVIN Liquid-Liquid Coalescers solve separation problems involving immiscible liquids.

Benefits

KEVIN’s superior technical support minimizes risk in process design and plant operations.

Introduction

KEVIN offers detailed engineering, manufacturing and technical support. Various models are manufactured to span the range of conditions encountered in many processes.

Materials of Construction

KEVIN Mist Eliminators – Liquid Coalescers are custom manufactured using materials specified by the client.

Model Numbers

KEVIN Mist Eliminators – Liquid Coalescers have model numbers based on their density, specific surface area and materials of construction. The Wire Mesh Mist Eliminators are termed as WIN - Mesh type & Vane Mist Eliminators are termed as WIN - Vane type.

Common Applications

Distillation Towers

Liquid entrainment can cause performance problems and limit capacity in packed and tray distillation towers. At intermediate draw-off trays, entrainment from below reduces product purity and can allow non-volatile contaminants into the draw-off liquid. The overhead gas product can also be contaminated with liquid entrainment.

The entrainment is eliminated by a properly designed Mist Eliminator.

Evaporators

Mist Eliminators reduce carryover of dissolved and un-dissolved solids to obtain specified steam condensate purity levels. This not only prevents product loss, but it also protects compressor internals in vapor recompression systems, provides boiler feed water quality condensate and prevents potential pollution problems.

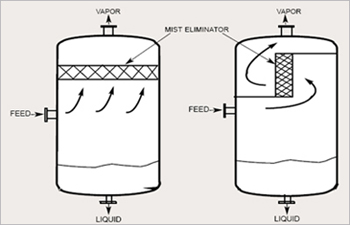

Knockout Drums

Designing knockout drums with Mist Eliminators reduce capital equipment costs and improve efficiency.

Scrubbers

From clean gas scrubbers and process vents to fouling services, such as flue gas desulphurization systems or steel mill blast furnace exhausts, Mist Eliminators help improve efficiency and capacity.

Steam Drums

Mist Eliminators reduce carryover of dissolved solids to obtain specified steam condensate purity levels.

Typical Process Applications

Flue Gas Desulphurization

High capacity, low pressure drop Vane Type Mist Eliminators provide excellent resistance to fouling.

Gas Absorption Systems

Systems using glycols, amines and other proprietary solvents removing contaminants from gas streams are optimized with Mist Eliminators to minimize losses of these expensive chemicals.

Refineries

Mist Eliminators in fractionators increase throughput capacity and allow deeper cuts for greater yields. In downstream crackers and reformers, mist eliminators prolong catalyst life by reducing carbon and metals in side draws.

Petrochemical Plants

Mist Eliminators are used in the knock-out drums of the compressor trains to extend compressor run length and service life. They are also used in quench towers to prevent contamination and protect downstream equipment.

Sizing and Installation

KEVIN Application Engineers should be consulted for sizing & installation