We are the manufacturers of Mineral Water Plants.

We are the manufacturers of Mineral Water Plants.

- Mineral water system and water treatment project to produce Final treated water as per IBWA / BIS Standards.

- Water Filling Machineries for PET bottles from 200 ml to 2000 ml.

- Water Filling Machineries for Jars of 5 Ltr – 20 Ltrs. Pouch Form, Fill & Seal Machine.

- Cup Rinsing, Filling & Foil Sealing Machine.

- PET Bottle Blowing Machines with ancillaries. Injection Moulding Machines

We are the manufacturers of Packaging Solution for Mineral Water.Packaging Solution for Mineral Waters offered can be made available by in both standard as well as customized operating specifications to choose from. Finding high demand in the mineral water processing industry, these plants are designed to precision handle different in-process requirements involving pre-treatment, filtration as well as disinfection of water among other processes. Further, the use of precision tuned parts & component support as well as latest technology support also make these provide for optimum water filtration interface and deliver safe bottled water for drinking purposes.

We are the manufacturers of Packaging Solution for Mineral Water.Packaging Solution for Mineral Waters offered can be made available by in both standard as well as customized operating specifications to choose from. Finding high demand in the mineral water processing industry, these plants are designed to precision handle different in-process requirements involving pre-treatment, filtration as well as disinfection of water among other processes. Further, the use of precision tuned parts & component support as well as latest technology support also make these provide for optimum water filtration interface and deliver safe bottled water for drinking purposes.

Special Features

- Precision designed and latest technology based machines offering process support in form of System Integrator

- Modern working interface that offers for complete one stop turnkey support for complete Packing needs

- Functional interface of the machine designed to handle complete beverage range comprising both Bottled as well as Packaged Drinking Water, Carbonated Soft Drinks as well as Non-Carbonated Beverage area

Specifications:

- Machines can handle packaging of cups in capacity of 200 / 250 ml

- Machines can handle packaging of pouches in capacity of 200 - 500ml

- Machines can handle packaging of PET Jars in capacity of 5 / 10 / 20 Liter

- Machines can handle packaging of PET bottles in capacity of 250/500/1000/2000ml

- Machines can handle packaging of Glass bottles containing carbonated beverage in capacity of 200 / 330ml

Applications:

- Packaged Drinking Water

- Non-Carbonated Beverage

We are the manufacturers of Filling Machine for Jars. Filling Machine for Jars are recognized in the industry for their capability to efficiently handle the requirements of filling liquids in both low as well as high viscosities through volumetric filling. With the machines being tested on defined parameters that assures their compliance with defined industry laid norms as well as standards, these Jar Filling Machines can also be manufactured in adherence with defined functional standards and norms as required by the customers. Some areas these are used in include for filling detergent, paints, syrups, edible oil, lubricants and other similar products.

We are the manufacturers of Filling Machine for Jars. Filling Machine for Jars are recognized in the industry for their capability to efficiently handle the requirements of filling liquids in both low as well as high viscosities through volumetric filling. With the machines being tested on defined parameters that assures their compliance with defined industry laid norms as well as standards, these Jar Filling Machines can also be manufactured in adherence with defined functional standards and norms as required by the customers. Some areas these are used in include for filling detergent, paints, syrups, edible oil, lubricants and other similar products.

Features:

- Highly functional range of filling machines for Jars

- Machines operating interface designed to handle filling of jars in different capacities

- Machines designed to deliver Fully automatic as well as Semi Automatic operation support

- Jar Filling Machines made available in capacities 5/10/20 Lts of Jar volume

Specifications:

We hold expertise in offering automatic as well as semi automatic interface based machines that are able to handle different jar filling outputs. Made available with washing and rinsing support, these machines can deliver outputs of:

- Filling output capacities of 60 Jars/Hr

- Filling output capacities of 120 / 240 Jars/Hr

- Filling output capacities of 350 / 500 Jars/Hr

Applications:

- Filling of Jars in different capacities

We are the manufacturers of Filling Machine for Cups (Plastic Glass). Filling Machine for Cups (Plastic Glass) offered are well recognized for their durable construction values as well as support provided in form of latest technologies which provides for their delivering optimum functional support in given end plastic cup filling processes. Needing almost zero maintenance costs, these are highly suitable for meeting the packaging needs of products like Ice cream, Yogurt, Honey, Buttermilk, Shrikhand and others. With the machines providing suitability for both filling as well as lid sealing of cups, these are also engineered to enhance the efficiency of work process.

We are the manufacturers of Filling Machine for Cups (Plastic Glass). Filling Machine for Cups (Plastic Glass) offered are well recognized for their durable construction values as well as support provided in form of latest technologies which provides for their delivering optimum functional support in given end plastic cup filling processes. Needing almost zero maintenance costs, these are highly suitable for meeting the packaging needs of products like Ice cream, Yogurt, Honey, Buttermilk, Shrikhand and others. With the machines providing suitability for both filling as well as lid sealing of cups, these are also engineered to enhance the efficiency of work process.

Features:

- Highly functional range of filling machines for plastic cups

- Machines featuring fully automatic operations

- Providing suitable support in operations involving Cups Rinsing, Filling & Foil Sealing processes

Working Specifications:

Cup filling machines are made available in varied outputs calculated on per minute basis. These include:

- 30 Cups/minimum output

- 60 Cups/minimum output

- 150 Cups/minimum output

- Machines can also be designed for other output capacities as desired by the customers

Applications:

- Filling & sealing of plastic glass cups in different capacities

We are the manufacturers of Fully Auto Jar Rinsing Filling Capping Machine. Fully Auto Jar Rinsing / Filling / Capping Machine offered feature advanced process technology as well as designing & construction support which provides for delivering optimum performance in involved rinsing, filling and capping operations. Precision managing the complete processes from feeding bottle for primary sterilization to its washing, secondary sterilization, rinsing, filling, capping and other involved processes, the precise functioning and automatic functional performance of these machines make these highly desired by the customers. These machines also come with heater support inside hot water tank for delivering sterilization as per FDA standards.

We are the manufacturers of Fully Auto Jar Rinsing Filling Capping Machine. Fully Auto Jar Rinsing / Filling / Capping Machine offered feature advanced process technology as well as designing & construction support which provides for delivering optimum performance in involved rinsing, filling and capping operations. Precision managing the complete processes from feeding bottle for primary sterilization to its washing, secondary sterilization, rinsing, filling, capping and other involved processes, the precise functioning and automatic functional performance of these machines make these highly desired by the customers. These machines also come with heater support inside hot water tank for delivering sterilization as per FDA standards.

Speacial Features:

- Machines designed to deliver Fully Automatic PLC Based operation support

- Machines featuring R-F-C Module that allows for operations with no human intervention required

- System designed to provide for low wastage in rinsing water

- Machine designed to deliver high speed operations

- Machines coming with desired safety feature that allows for no Rinse/Fill/Cap operations in absence of Jar

Specifications:

- Machines designed to deliver 3 Stage Rinsing

- Machines coming with production capacity from 2-20 Jars/min

- All contact parts of machines made using SS 316 metal that provides for contamination free as well as long-lasting usage

Applications:

- For handling Jar Rinsing / Filling / Capping operations

We are the manufacturers of Fully Auto Blow Moulding Machines. Fully Auto Blow Moulding Machines offered are backed by latest technology support so as to provide for optimal functional usage in given applications. Made available with user friendly working interface, these machines are also in compliance with defined industry standards and are recognized for precision engineering designs, optimum performance support, longer service life as well as high process efficiency standards.

We are the manufacturers of Fully Auto Blow Moulding Machines. Fully Auto Blow Moulding Machines offered are backed by latest technology support so as to provide for optimal functional usage in given applications. Made available with user friendly working interface, these machines are also in compliance with defined industry standards and are recognized for precision engineering designs, optimum performance support, longer service life as well as high process efficiency standards.

These are highly suitable for PET blowing of bottles in different size capacities as required.

Features:

- Rich industry expertise in offering highly functional and latest technology based and fully automatic PET blow molding

machines

Specifications:

These automatic interface based PET blowing machines are made available in different output capacities. These include:

- PET blowing support for 2000 Bottles on per hr basis

- PET blowing support for 3600 Bottles on per hr basis

- PET blowing support for 6000 Bottles on per hr basis

Applications:

- Blow moulding of PET bottles

We are the manufacturers of Rinser Filler Capper Machine For Soft Drinks. Rinser Filler Capper Machine for Soft Drinks offered are designed to precision handle the process requirements involving filling and capping of soft drink bottles. With the machine designed to perform integrated operations at larger speeds as well as for different volumes, the process support is also provided in form of programmable PLC as well as convertor & photoelectric elements that allows for precision handling of the operations involving precise torque of capping and filling operations.

We are the manufacturers of Rinser Filler Capper Machine For Soft Drinks. Rinser Filler Capper Machine for Soft Drinks offered are designed to precision handle the process requirements involving filling and capping of soft drink bottles. With the machine designed to perform integrated operations at larger speeds as well as for different volumes, the process support is also provided in form of programmable PLC as well as convertor & photoelectric elements that allows for precision handling of the operations involving precise torque of capping and filling operations.

Special Features:

- Complete Filling Line for Filling Carbonated Water

- Also suitable for filling, rinsing and capping of Carbonated Flavored Soft Drinks

- Suitable to handle PET Bottles

Working Specifications:

- Can handle processing of bottles from 250 ml to 2250 ml

- Machines working on principle of Counter Pressure Filling

- Machines available in working capacity of up to 200 bottles per hour

- We can also provide in these provision of ionized air rinsing for higher capacity lines

Applications:

- Provides support for Rinser Filler Capper operations in areas of Soft Drink bottling

We are the manufacturers and exporters of Fully Auto Pet Bottle Rinsing Filling and Capping Machine. Highly suitable for mineral water packaging solutions like rinsing, filling and capping, we offer our range of Fully Auto Pet Bottle Rinsing Filling and Capping Machine that can also be custom build as per the requirement of the clients. Designed and fabricated using quality raw materials, these are user friendly and safe to operate. Moreover, these machines are multi-functioning and helps in saving time and cost.

We are the manufacturers and exporters of Fully Auto Pet Bottle Rinsing Filling and Capping Machine. Highly suitable for mineral water packaging solutions like rinsing, filling and capping, we offer our range of Fully Auto Pet Bottle Rinsing Filling and Capping Machine that can also be custom build as per the requirement of the clients. Designed and fabricated using quality raw materials, these are user friendly and safe to operate. Moreover, these machines are multi-functioning and helps in saving time and cost.

Other salient features of these machines are:

- Maximum filling capacity: 100mlto2&20litres

- Maximum output: 24/30/40/60bottlespermin

- Manufactured according to the GMP norms

- Rotary compact line for inducing efficiency in packing

We are the manufacturers of Filling Machines For PET Bottles. Filling Machines for PET Bottles offered are made available by us in world class design standards that meet the filling needs of PET bottles. With the machines finding application in different industry sectors, the precision construction standards of the systems assist in ensuring these matches up with the specific process needs at client’s end. Some areas these are used in include for filling of products like natural juice, milk, mineral water, synthetic juice, carbonated drink and others.

We are the manufacturers of Filling Machines For PET Bottles. Filling Machines for PET Bottles offered are made available by us in world class design standards that meet the filling needs of PET bottles. With the machines finding application in different industry sectors, the precision construction standards of the systems assist in ensuring these matches up with the specific process needs at client’s end. Some areas these are used in include for filling of products like natural juice, milk, mineral water, synthetic juice, carbonated drink and others.

Special Features

- Rich industry experience in offering filling machinery interface for PET bottles

- Machines made available in Fully & Semi Automatic working possibilities

- Can handle filling of PET bottles in different functional capacities

Specifications:

Filling Machines made available for PET Bottles with bottle handling capacity from 200 ml to 2000 ml. Some of the outputs these machines can deliver include:

- PET bottle filling capacity of 25 Bottle/min (BPM)

- PET bottle filling capacity of 50 BPM / 75 BPM

- PET bottle filling capacity of 120 BPM / 150 BPM

- PET bottle filling capacity of 200 / 300 / 400 BPM

- The filling capacity of the machines for PET bottles can also be customized as desired by the customers

Applications:

- Filling of PET bottles in different capacities

We are the manufacturers of Semi Auto Jar Rinsing Filling Capping Machine. Semi Auto Jar Rinsing / Filling / Capping Machine offered find wide application in varied industry sectors for handling the rinsing, filling and capping processes of jars. The precision functional support provided by these machines also make these provide for optimum performance at lower as well as higher operating speeds. For delivering complete reliability in operations, these machines also undergo stringent testing under different process stages as per set parameters. Further, the parts used in these jar filling machines also makes the system deliver optimum durability and consistent working support.

We are the manufacturers of Semi Auto Jar Rinsing Filling Capping Machine. Semi Auto Jar Rinsing / Filling / Capping Machine offered find wide application in varied industry sectors for handling the rinsing, filling and capping processes of jars. The precision functional support provided by these machines also make these provide for optimum performance at lower as well as higher operating speeds. For delivering complete reliability in operations, these machines also undergo stringent testing under different process stages as per set parameters. Further, the parts used in these jar filling machines also makes the system deliver optimum durability and consistent working support.

Speacial Features:

- Machines available with easy to use interface

- Modular designs of the machine also takes less storage space

- Machines requiring low capital investment

- Operations of the machine requiring low power

- Functional interface of the machines provided for allowing low wastage in rinsing water

- Machines precision designed for handling lower operating speeds

Specifications:

- All machine contact Parts made available in SS 316 metal finish

- Machine designed to handle production rates from 2 - 4 Jars/min

Applications:

- For handling Jar Rinsing / Filling / Capping operations

We are the manufacturers of Water Treatment System. Water Treatment System finds application in meeting the demands of effective filtration of impurities as well as chemicals that are present in water and thus restoring the water quality standards and make it fit for particular usage in given applications. With the systems designed and developed as per defined industry norms, these are also known for easy installation as well as availability in customized finish sizes as demanded by the customers.

We are the manufacturers of Water Treatment System. Water Treatment System finds application in meeting the demands of effective filtration of impurities as well as chemicals that are present in water and thus restoring the water quality standards and make it fit for particular usage in given applications. With the systems designed and developed as per defined industry norms, these are also known for easy installation as well as availability in customized finish sizes as demanded by the customers.

Features:

- Optimum functionality based water treatment systems

- Water systems comprising Chlorine Dosing system, Multi Media Filtration, Activated Carbon Filtration

- Systems can also be provided with Water Softening as well as Ultra Filtration (Optional)

- Systems featuring provision for Reverse Osmosis, UV Sterilization and Ozone Disinfection so as to deliver

optimum processed water quality

- Storage Tank made available in stainless steel construction

- System coming with provision of Micron Cartridge Filtration (0.2 Micron)

Applications:

- For water treatment processes

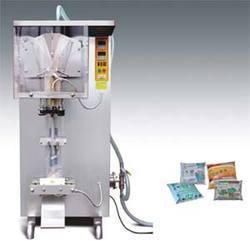

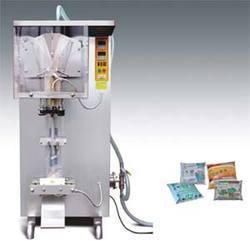

We are the manufacturers of Pouches Filling Machine (Water Bags Filling Machine). Filling Machine for Pouches (Water Bags) offered are backed by latest technology support as well as modular construction that makes these optimally perform the processes involving packing of water in pouch form. With the machines delivering process support in form of filling as well as sealing of pouches, these are precision fabricated by professional experts and come tested for defined process quality features at different levels of production. Delivering optimum performance, the machinery range can also be custom tuned to pack viscous liquid as per desired specifications of customers.

We are the manufacturers of Pouches Filling Machine (Water Bags Filling Machine). Filling Machine for Pouches (Water Bags) offered are backed by latest technology support as well as modular construction that makes these optimally perform the processes involving packing of water in pouch form. With the machines delivering process support in form of filling as well as sealing of pouches, these are precision fabricated by professional experts and come tested for defined process quality features at different levels of production. Delivering optimum performance, the machinery range can also be custom tuned to pack viscous liquid as per desired specifications of customers.

Features:

- Latest technology based range of filling machines for pouches

- Machines featuring Fully Automatic operation support

- Machines offering easy to handle operating interface comprising Pouch Filling & Sealing operations in an optimal way.

Specifications:

Our rich industry expertise as well as latest technology knowhow allows us to deliver optimum functionality based range of water pouch filling and sealing machines. Here, our expertise lies in offering these in following operating configurations:

- Pouch output capacities of 32 Pouches/min

- Pouch output capacities of 64 Pouches/min

Applications:

- Filling & sealing of water pouches in different capacities

We are the manufacturers of Semi Auto Blow Moulding Machine. Semi Auto Blow Moulding Machines are engineered to perfectly match up with the specific working needs of different related industry sectors. Providing for optimum molding interface, these machines can also be availed in different technical specifications as per client’s requirement for PET Blowing. Further, these can be made available in different working capacities from 600, 1200 and 2000 bottles on per hour basis.

We are the manufacturers of Semi Auto Blow Moulding Machine. Semi Auto Blow Moulding Machines are engineered to perfectly match up with the specific working needs of different related industry sectors. Providing for optimum molding interface, these machines can also be availed in different technical specifications as per client’s requirement for PET Blowing. Further, these can be made available in different working capacities from 600, 1200 and 2000 bottles on per hour basis.

Features:

- Highly functional range of Semi Auto Blow Moulding Machines

- Machines made available in Fully & Semi Automatic operation support

- Suitable for meeting the process application demands

Specifications:

We are offering latest technology based PET blowing machines that are made available in different output capacities. These include:

- PET blowing support for 600 Bottles on per hr basis

- PET blowing support for 1200 Bottles on per hr basis

- PET blowing support for 2000 Bottles on per hr basis

Applications:

- Blow moulding of PET bottles

We are the manufacturers of Linear Auto Cup Rinsing Filling and Sealing Machine. Linear Auto Cup Rinsing Filling & Foil Sealing Machines offered are backed by latest technology support and find application in industry sectors dealing in processing of end products like milk, juices, mineral water and other similar products in liquid form. With the end fabrication standards of these machines delivered as per norms and standards of BIS, these provide for automatic loading and unloading operations as well as with multiple filling head provisions depending on production process requirements.

We are the manufacturers of Linear Auto Cup Rinsing Filling and Sealing Machine. Linear Auto Cup Rinsing Filling & Foil Sealing Machines offered are backed by latest technology support and find application in industry sectors dealing in processing of end products like milk, juices, mineral water and other similar products in liquid form. With the end fabrication standards of these machines delivered as per norms and standards of BIS, these provide for automatic loading and unloading operations as well as with multiple filling head provisions depending on production process requirements.

Features:

- Optimum functionality based Linear Auto Cup Rinsing Filling & Foil Sealing systems

- Machines designed for allowing automatic operations involving Loading & Unloading of cups

- Coming with working arrangement of no Cup-No Rinse/Fill/Seal process

- Can be made available with optional Out-feed conveyor

- Can be made available with optional Batch Printer

Specifications:

- Made available in production capacities from 30 to 200 Cups/min

- Machines designed to deliver volume capacities from 100 to 300ml

- Suitable for meeting the processing needs of products like Juice, Milk, Mineral Water

- Supporting fixing of lids made available in Laminated Film/Pre-cut All. Foil material

- For optimum functional support all machine contact Parts made available in SS 316 material finish

- Machines approved as per BIS standards

Applications:

- Used for Cup Rinsing Filling & Foil Sealing procedures

We are the manufacturers of Packaged Drinking Water Plants. Packaged Drinking Water Plants offered by us are backed by latest technology support that matches up with the defined water purification demands. Coming with advanced purification process, these functional processes of these drinking water plants ensure optimum functional support is provided in gaining purified water as per internationally approved norms. Further, these plants also provide for high efficiency operations as well as also require less maintenance support while handling varied purifications processes involving rinsing, filling, capping as well as water sterilization using oxidants and filtration techniques.

We are the manufacturers of Packaged Drinking Water Plants. Packaged Drinking Water Plants offered by us are backed by latest technology support that matches up with the defined water purification demands. Coming with advanced purification process, these functional processes of these drinking water plants ensure optimum functional support is provided in gaining purified water as per internationally approved norms. Further, these plants also provide for high efficiency operations as well as also require less maintenance support while handling varied purifications processes involving rinsing, filling, capping as well as water sterilization using oxidants and filtration techniques.

Features:

- Wide range of ECO series Bottled Mineral Water Plants/Packaged Drinking Water Plants

- Plants falling in compliance with BIS guidelines

- Treatment Plants ideally suited for usage in processing of Packaged Drinking Water, Bottled Mineral Water, Beverages and Juices, Carbonated & Non-Carbonated Soft Drinks and other similar processes

Specifications:

- Can be made available in different functional capacities that range from 500 LPH to 100,000 PH

- This capacity can also be customized as demanded by the customers

- Makes use of FRP vessels as well as stainless steel 304 piping support

- Also made available with Skid provision as an optional choice

- Can also offer bigger capacity Plants featuring use of Mild Steel Vessels

- Coming coated both internally as well as externally using Food Grade Epoxy so as to provide for optimum service life

- SS 316 finish provided for Micron Bag UV systems, Filters and Cartridge Filters

We are the manufacturers of Mineral Water Plants.

We are the manufacturers of Mineral Water Plants.

We are the manufacturers of Packaging Solution for Mineral Water.Packaging Solution for Mineral Waters offered can be made available by in both standard as well as customized operating specifications to choose from. Finding high demand in the mineral water processing industry, these plants are designed to precision handle different in-process requirements involving pre-treatment, filtration as well as disinfection of water among other processes. Further, the use of precision tuned parts & component support as well as latest technology support also make these provide for optimum water filtration interface and deliver safe bottled water for drinking purposes.

We are the manufacturers of Packaging Solution for Mineral Water.Packaging Solution for Mineral Waters offered can be made available by in both standard as well as customized operating specifications to choose from. Finding high demand in the mineral water processing industry, these plants are designed to precision handle different in-process requirements involving pre-treatment, filtration as well as disinfection of water among other processes. Further, the use of precision tuned parts & component support as well as latest technology support also make these provide for optimum water filtration interface and deliver safe bottled water for drinking purposes. We are the manufacturers of Filling Machine for Jars. Filling Machine for Jars are recognized in the industry for their capability to efficiently handle the requirements of filling liquids in both low as well as high viscosities through volumetric filling. With the machines being tested on defined parameters that assures their compliance with defined industry laid norms as well as standards, these Jar Filling Machines can also be manufactured in adherence with defined functional standards and norms as required by the customers. Some areas these are used in include for filling detergent, paints, syrups, edible oil, lubricants and other similar products.

We are the manufacturers of Filling Machine for Jars. Filling Machine for Jars are recognized in the industry for their capability to efficiently handle the requirements of filling liquids in both low as well as high viscosities through volumetric filling. With the machines being tested on defined parameters that assures their compliance with defined industry laid norms as well as standards, these Jar Filling Machines can also be manufactured in adherence with defined functional standards and norms as required by the customers. Some areas these are used in include for filling detergent, paints, syrups, edible oil, lubricants and other similar products. We are the manufacturers of Filling Machine for Cups (Plastic Glass). Filling Machine for Cups (Plastic Glass) offered are well recognized for their durable construction values as well as support provided in form of latest technologies which provides for their delivering optimum functional support in given end plastic cup filling processes. Needing almost zero maintenance costs, these are highly suitable for meeting the packaging needs of products like Ice cream, Yogurt, Honey, Buttermilk, Shrikhand and others. With the machines providing suitability for both filling as well as lid sealing of cups, these are also engineered to enhance the efficiency of work process.

We are the manufacturers of Filling Machine for Cups (Plastic Glass). Filling Machine for Cups (Plastic Glass) offered are well recognized for their durable construction values as well as support provided in form of latest technologies which provides for their delivering optimum functional support in given end plastic cup filling processes. Needing almost zero maintenance costs, these are highly suitable for meeting the packaging needs of products like Ice cream, Yogurt, Honey, Buttermilk, Shrikhand and others. With the machines providing suitability for both filling as well as lid sealing of cups, these are also engineered to enhance the efficiency of work process. We are the manufacturers of Fully Auto Jar Rinsing Filling Capping Machine. Fully Auto Jar Rinsing / Filling / Capping Machine offered feature advanced process technology as well as designing & construction support which provides for delivering optimum performance in involved rinsing, filling and capping operations. Precision managing the complete processes from feeding bottle for primary sterilization to its washing, secondary sterilization, rinsing, filling, capping and other involved processes, the precise functioning and automatic functional performance of these machines make these highly desired by the customers. These machines also come with heater support inside hot water tank for delivering sterilization as per FDA standards.

We are the manufacturers of Fully Auto Jar Rinsing Filling Capping Machine. Fully Auto Jar Rinsing / Filling / Capping Machine offered feature advanced process technology as well as designing & construction support which provides for delivering optimum performance in involved rinsing, filling and capping operations. Precision managing the complete processes from feeding bottle for primary sterilization to its washing, secondary sterilization, rinsing, filling, capping and other involved processes, the precise functioning and automatic functional performance of these machines make these highly desired by the customers. These machines also come with heater support inside hot water tank for delivering sterilization as per FDA standards. We are the manufacturers of Fully Auto Blow Moulding Machines. Fully Auto Blow Moulding Machines offered are backed by latest technology support so as to provide for optimal functional usage in given applications. Made available with user friendly working interface, these machines are also in compliance with defined industry standards and are recognized for precision engineering designs, optimum performance support, longer service life as well as high process efficiency standards.

We are the manufacturers of Fully Auto Blow Moulding Machines. Fully Auto Blow Moulding Machines offered are backed by latest technology support so as to provide for optimal functional usage in given applications. Made available with user friendly working interface, these machines are also in compliance with defined industry standards and are recognized for precision engineering designs, optimum performance support, longer service life as well as high process efficiency standards.  We are the manufacturers of Rinser Filler Capper Machine For Soft Drinks. Rinser Filler Capper Machine for Soft Drinks offered are designed to precision handle the process requirements involving filling and capping of soft drink bottles. With the machine designed to perform integrated operations at larger speeds as well as for different volumes, the process support is also provided in form of programmable PLC as well as convertor & photoelectric elements that allows for precision handling of the operations involving precise torque of capping and filling operations.

We are the manufacturers of Rinser Filler Capper Machine For Soft Drinks. Rinser Filler Capper Machine for Soft Drinks offered are designed to precision handle the process requirements involving filling and capping of soft drink bottles. With the machine designed to perform integrated operations at larger speeds as well as for different volumes, the process support is also provided in form of programmable PLC as well as convertor & photoelectric elements that allows for precision handling of the operations involving precise torque of capping and filling operations.  We are the manufacturers and exporters of Fully Auto Pet Bottle Rinsing Filling and Capping Machine. Highly suitable for mineral water packaging solutions like rinsing, filling and capping, we offer our range of Fully Auto Pet Bottle Rinsing Filling and Capping Machine that can also be custom build as per the requirement of the clients. Designed and fabricated using quality raw materials, these are user friendly and safe to operate. Moreover, these machines are multi-functioning and helps in saving time and cost.

We are the manufacturers and exporters of Fully Auto Pet Bottle Rinsing Filling and Capping Machine. Highly suitable for mineral water packaging solutions like rinsing, filling and capping, we offer our range of Fully Auto Pet Bottle Rinsing Filling and Capping Machine that can also be custom build as per the requirement of the clients. Designed and fabricated using quality raw materials, these are user friendly and safe to operate. Moreover, these machines are multi-functioning and helps in saving time and cost. We are the manufacturers of Filling Machines For PET Bottles. Filling Machines for PET Bottles offered are made available by us in world class design standards that meet the filling needs of PET bottles. With the machines finding application in different industry sectors, the precision construction standards of the systems assist in ensuring these matches up with the specific process needs at client’s end. Some areas these are used in include for filling of products like natural juice, milk, mineral water, synthetic juice, carbonated drink and others.

We are the manufacturers of Filling Machines For PET Bottles. Filling Machines for PET Bottles offered are made available by us in world class design standards that meet the filling needs of PET bottles. With the machines finding application in different industry sectors, the precision construction standards of the systems assist in ensuring these matches up with the specific process needs at client’s end. Some areas these are used in include for filling of products like natural juice, milk, mineral water, synthetic juice, carbonated drink and others. We are the manufacturers of Semi Auto Jar Rinsing Filling Capping Machine. Semi Auto Jar Rinsing / Filling / Capping Machine offered find wide application in varied industry sectors for handling the rinsing, filling and capping processes of jars. The precision functional support provided by these machines also make these provide for optimum performance at lower as well as higher operating speeds. For delivering complete reliability in operations, these machines also undergo stringent testing under different process stages as per set parameters. Further, the parts used in these jar filling machines also makes the system deliver optimum durability and consistent working support.

We are the manufacturers of Semi Auto Jar Rinsing Filling Capping Machine. Semi Auto Jar Rinsing / Filling / Capping Machine offered find wide application in varied industry sectors for handling the rinsing, filling and capping processes of jars. The precision functional support provided by these machines also make these provide for optimum performance at lower as well as higher operating speeds. For delivering complete reliability in operations, these machines also undergo stringent testing under different process stages as per set parameters. Further, the parts used in these jar filling machines also makes the system deliver optimum durability and consistent working support. We are the manufacturers of Water Treatment System. Water Treatment System finds application in meeting the demands of effective filtration of impurities as well as chemicals that are present in water and thus restoring the water quality standards and make it fit for particular usage in given applications. With the systems designed and developed as per defined industry norms, these are also known for easy installation as well as availability in customized finish sizes as demanded by the customers.

We are the manufacturers of Water Treatment System. Water Treatment System finds application in meeting the demands of effective filtration of impurities as well as chemicals that are present in water and thus restoring the water quality standards and make it fit for particular usage in given applications. With the systems designed and developed as per defined industry norms, these are also known for easy installation as well as availability in customized finish sizes as demanded by the customers. We are the manufacturers of Pouches Filling Machine (Water Bags Filling Machine). Filling Machine for Pouches (Water Bags) offered are backed by latest technology support as well as modular construction that makes these optimally perform the processes involving packing of water in pouch form. With the machines delivering process support in form of filling as well as sealing of pouches, these are precision fabricated by professional experts and come tested for defined process quality features at different levels of production. Delivering optimum performance, the machinery range can also be custom tuned to pack viscous liquid as per desired specifications of customers.

We are the manufacturers of Pouches Filling Machine (Water Bags Filling Machine). Filling Machine for Pouches (Water Bags) offered are backed by latest technology support as well as modular construction that makes these optimally perform the processes involving packing of water in pouch form. With the machines delivering process support in form of filling as well as sealing of pouches, these are precision fabricated by professional experts and come tested for defined process quality features at different levels of production. Delivering optimum performance, the machinery range can also be custom tuned to pack viscous liquid as per desired specifications of customers. We are the manufacturers of Semi Auto Blow Moulding Machine. Semi Auto Blow Moulding Machines are engineered to perfectly match up with the specific working needs of different related industry sectors. Providing for optimum molding interface, these machines can also be availed in different technical specifications as per client’s requirement for PET Blowing. Further, these can be made available in different working capacities from 600, 1200 and 2000 bottles on per hour basis.

We are the manufacturers of Semi Auto Blow Moulding Machine. Semi Auto Blow Moulding Machines are engineered to perfectly match up with the specific working needs of different related industry sectors. Providing for optimum molding interface, these machines can also be availed in different technical specifications as per client’s requirement for PET Blowing. Further, these can be made available in different working capacities from 600, 1200 and 2000 bottles on per hour basis. We are the manufacturers of Linear Auto Cup Rinsing Filling and Sealing Machine. Linear Auto Cup Rinsing Filling & Foil Sealing Machines offered are backed by latest technology support and find application in industry sectors dealing in processing of end products like milk, juices, mineral water and other similar products in liquid form. With the end fabrication standards of these machines delivered as per norms and standards of BIS, these provide for automatic loading and unloading operations as well as with multiple filling head provisions depending on production process requirements.

We are the manufacturers of Linear Auto Cup Rinsing Filling and Sealing Machine. Linear Auto Cup Rinsing Filling & Foil Sealing Machines offered are backed by latest technology support and find application in industry sectors dealing in processing of end products like milk, juices, mineral water and other similar products in liquid form. With the end fabrication standards of these machines delivered as per norms and standards of BIS, these provide for automatic loading and unloading operations as well as with multiple filling head provisions depending on production process requirements. We are the manufacturers of Packaged Drinking Water Plants. Packaged Drinking Water Plants offered by us are backed by latest technology support that matches up with the defined water purification demands. Coming with advanced purification process, these functional processes of these drinking water plants ensure optimum functional support is provided in gaining purified water as per internationally approved norms. Further, these plants also provide for high efficiency operations as well as also require less maintenance support while handling varied purifications processes involving rinsing, filling, capping as well as water sterilization using oxidants and filtration techniques.

We are the manufacturers of Packaged Drinking Water Plants. Packaged Drinking Water Plants offered by us are backed by latest technology support that matches up with the defined water purification demands. Coming with advanced purification process, these functional processes of these drinking water plants ensure optimum functional support is provided in gaining purified water as per internationally approved norms. Further, these plants also provide for high efficiency operations as well as also require less maintenance support while handling varied purifications processes involving rinsing, filling, capping as well as water sterilization using oxidants and filtration techniques.