Gaskets for Flanges / Cork Products

Cork Sheet, Rubberised Cork Sheet, Gasket and components also

Cork Sheet, Rubberised Cork Sheet, Gasket and components also

other Cork Material for Vibration Control, Sound and Thermal Insulation

For sealing Pressures and Vacuum to 175 KG/CM2 and Temperatures upto 5600C in Flanged Joints, Boiler,

Tube caps, Hand holes, Manholes...Against Oils, Steam, Gases and Liquids.

Applications Include Oil Refineries, Chemical, Petro Chemical, Marine, Power Plants, Pulp and Paper and other Processing Plants.

Spiral Wound Gaskets

| 150 | 300 | 400 | 600 | 900 | a1500 | 2500 | |||||||||||||||

| D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | |

| 1/2B | 19.0 | 31.8 | 47.8 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 63.5 | 19.0 | 31.8 | 63.5 | 19.0 | 31.8 | 69.8 |

| 3/4 | 5.4 | 39.6 | 57.2 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 69.8 | 25.4 | 39.6 | 69.8 | 25.4 | 39.6 | 76.2 |

| 1 | 31.8 | 47.8 | 66.8 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 79.5 | 31.8 | 47.8 | 79.5 | 31.8 | 47.8 | 85.8 |

| 11/4 | 47.8 | 60.4 | 76.2 | 47.8 | 60.4 | 82.6 | 47.8 | 60.4 | 82.6 | 47.8 | 60.4 | 82.6 | 39.6 | 60.4 | 88.9 | 39.6 | 60.4 | 88.9 | 39.6 | 60.4 | 104.9 |

| 11/2 | 54.1 | 69.8 | 85.8 | 54.1 | 69.8 | 95.2 | 54.1 | 69.8 | 95.2 | 54.1 | 69.8 | 95.2 | 47.8 | 69.8 | 98.6 | 47.8 | 69.8 | 98.6 | 47.8 | 69.8 | 117.6 |

| 2 | 69.8 | 85.8 | 104.9 | 69.8 | 85.8 | 111.2 | 69.8 | 85.8 | 111.2 | 69.8 | 85.8 | 111.2 | 58.7 | 85.8 | 143.0 | 58.7 | 85.8 | 143.0 | 58.7 | 85.8 | 146.0 |

| 2 1/2 | 82.6 | 98.6 | 124.0 | 82.6 | 98.6 | 130.3 | 82.6 | 98.6 | 130.3 | 82.6 | 98.6 | 130.3 | 69.8 | 98.6 | 165.1 | 69.8 | 98.6 | 165.1 | 69.8 | 98.6 | 168.4 |

| 3 | 101.6 | 120.6 | 136.6 | 101.6 | 120.6 | 149.4 | 101.6 | 120.6 | 149.4 | 101.6 | 120.6 | 149.4 | 95.2 | 120.6 | 168.4 | 92.2 | 120.6 | 174.8 | 92.2 | 120.6 | 196.8 |

| 4 | 127.0 | 149.4 | 174.8 | 127.0 | 149.4 | 181.1 | 120.6 | 149.4 | 177.8 | 120.6 | 149.4 | 193.8 | 120.6 | 149.4 | 209.6 | 117.6 | 149.4 | 209.6 | 117.6 | 149.4 | 235.0 |

| 5 | 155.7 | 177.8 | 196.8 | 155.7 | 177.8 | 215.9 | 147.6 | 177.8 | 212.8 | 147.6 | 177.8 | 241.3 | 147.6 | 177.8 | 247.6 | 143.0 | 177.8 | 254.0 | 143.0 | 177.8 | 279.4 |

| 6 | 182.6 | 209.6 | 222.2 | 182.6 | 209.6 | 251.0 | 174.8 | 209.6 | 247.6 | 174.8 | 209.6 | 266.7 | 174.8 | 209.6 | 289.0 | 171.4 | 209.6 | 282.7 | 171.4 | 209.6 | 317.5 |

| 8 | 233.4 | 263.6 | 279.4 | 233.4 | 263.6 | 308.1 | 255.6 | 263.6 | 604.8 | 255.6 | 263.6 | 320.8 | 222.2 | 257.3 | 358.9 | 215.9 | 257.3 | 352.6 | 216.9 | 257.3 | 387.4 |

| 10 | 287.3 | 317.5 | 339.8 | 287.3 | 317.5 | 362.0 | 274.6 | 317.5 | 358.9 | 274.6 | 317.5 | 400.0 | 276.4 | 311.2 | 435.1 | 266.7 | 311.2 | 435.1 | 270.0 | 311.2 | 476.2 |

| 12 | 339.8 | 374.6 | 409.7 | 339.8 | 374.6 | 422.4 | 327.2 | 374.6 | 419.1 | 327.2 | 374.6 | 457.2 | 323.8 | 368.3 | 498.6 | 323.8 | 368.3 | 520.7 | 317.5 | 368.3 | 549.4 |

| 14 | 371.6 | 406.4 | 450.8 | 371.6 | 406.4 | 485.9 | 362.0 | 406.4 | 482.6 | 362.0 | 406.4 | 492.2 | 355.6 | 400.0 | 520.7 | 362.0 | 400.0 | 577.8 | - | - | - |

| 16 | 422.4 | 463.6 | 514.1 | 422.4 | 463.6 | 539.8 | 412.8 | 463.6 | 536.7 | 412.8 | 463.6 | 565.2 | 412.8 | 457.2 | 574.8 | 406.4 | 457.2 | 641.1 | - | - | - |

| 18 | 474.7 | 527.0 | 549.4 | 474.7 | 527.0 | 596.9 | 469.9 | 527.0 | 593.8 | 469.9 | 527.0 | 612.9 | 463.6 | 520.7 | 638.3 | 463.6 | 520.7 | 704.8 | - | - | |

| 20 | 525.5 | 577.8 | 606.6 | 525.5 | 577.8 | 654.0 | 520.7 | 577.8 | 647.7 | 520.7 | 577.8 | 682.8 | 520.7 | 571.5 | 698.5 | 514.4 | 571.5 | 755.6 | - | - | - |

| 24 | 628.6 | 685.8 | 717.6 | 628.6 | 685.8 | 774.7 | 628.6 | 685.8 | 768.4 | 628.6 | 685.8 | 790.7 | 628.6 | 679.4 | 838.2 | 616.0 | 679.4 | 901.7 | - | - | - |

| & nbsp; | 150 | 300 | 400 | 600 | 900 | a1500 | 2500 | ||||||||||||||

| D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | D2 | D3 | D4 | |

| 1/2B | 19.0 | 31.8 | 47.8 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 54.1 | 19.0 | 31.8 | 63.5 | 19.0 | 31.8 | 63.5 | 19.0 | 31.8 | 69.8 |

| 3/4 | 25.4 | 39.6 | 57.2 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 66.8 | 25.4 | 39.6 | 69.8 | 25.4 | 39.6 | 69.8 | 25.4 | 39.6 | 76.2 |

| 1 | 31.8 | 47.8 | 66.8 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 73.2 | 31.8 | 47.8 | 79.5 | 31.8 | 47.8 | 79.5 | 31.8 | 47.8 | 85.8 |

| 11/4 | 47.8 | 60.4 | 76.2 | 47.8 | 60.4 | 82.6 | 47.8 | 60.4 | 82.6 | 47.8 | 60.4 | 82.6 | 39.6 | 60.4 | 88.9 | 39.6 | 60.4 | 88.9 | 39.6 | 60.4 | 104.9 |

| 11/2 | 54.1 | 69.8 | 85.8 | 54.1 | 69.8 | 95.2 | 54.1 | 69.8 | 95.2 | 54.1 | 69.8 | 95.2 | 47.8 | 69.8 | 98.6 | 47.8 | 69.8 | 98.6 | 47.8 | 69.8 | 117.6 |

| 2 | 69.8 | 85.8 | 104.9 | 69.8 | 85.8 | 111.2 | 69.8 | 85.8 | 111.2 | 69.8 | 85.8 | 111.2 | 58.7 | 85.8 | 143.0 | 58.7 | 85.8 | 143.0 | 58.7 | 85.8 | 146.0 |

| 2 1/2 | 82.6 | 98.6 | 124.0 | 82.6 | 98.6 | 130.3 | 82.6 | 98.6 | 130.3 | 82.6 | 98.6 | 130.3 | 69.8 | 98.6 | 165.1 | 69.8 | 98.6 | 165.1 | 69.8 | 98.6 | 168.4 |

| 3 | 101.6 | 120.6 | 136.6 | 101.6 | 120.6 | 149.4 | 101.6 | 120.6 | 149.4 | 101.6 | 120.6 | 149.4 | 95.2 | 120.6 | 168.4 | 92.2 | 120.6 | 174.8 | 92.2 | 120.6 | 196.8 |

| 4 | 127.0 | 149.4 | 174.8 | 127.0 | 149.4 | 181.1 | 120.6 | 149.4 | 177.8 | 120.6 | 149.4 | 193.8 | 120.6 | 149.4 | 209.6 | 117.6 | 149.4 | 209.6 | 117.6 | 149.4 | 235.0 |

| 5 | 155.7 | 177.8 | 196.8 | 155.7 | 177.8 | 215.9 | 147.6 | 177.8 | 212.8 | 147.6 | 177.8 | 241.3 | 147.6 | 177.8 | 247.6 | 143.0 | 177.8 | 254.0 | 143.0 | 177.8 | 279.4 |

| 6 | 182.6 | 209.6 | 222.2 | 182.6 | 209.6 | 251.0 | 174.8 | 209.6 | 247.6 | 174.8 | 209.6 | 266.7 | 174.8 | 209.6 | 289.0 | 171.4 | 209.6 | 282.7 | 171.4 | 209.6 | 317.5 |

| 8 | 233.4 | 263.6 | 279.4 | 233.4 | 263.6 | 308.1 | 255.6 | 263.6 | 604.8 | 255.6 | 263.6 | 320.8 | 222.2 | 257.3 | 358.9 | 215.9 | 257.3 | 352.6 | 216.9 | 257.3 | 387.4 |

| 10 | 287.3 | 317.5 | 339.8 | 287.3 | 317.5 | 362.0 | 274.6 | 317.5 | 358.9 | 274.6 | 317.5 | 400.0 | 276.4 | 311.2 | 435.1 | 266.7 | 311.2 | 435.1 | 270.0 | 311.2 | 476.2 |

| 12 | 339.8 | 374.6 | 409.7 | 339.8 | 374.6 | 422.4 | 327.2 | 374.6 | 419.1 | 327.2 | 374.6 | 457.2 | 323.8 | 368.3 | 498.6 | 323.8 | 368.3 | 520.7 | 317.5 | 368.3 | 549.4 |

| 14 | 371.6 | 406.4 | 450.8 | 371.6 | 406.4 | 485.9 | 362.0 | 406.4 | 482.6 | 362.0 | 406.4 | 492.2 | 355.6 | 400.0 | 520.7 | 362.0 | 400.0 | 577.8 | - | - | - |

| 16 | 422.4 | 463.6 | 514.1 | 422.4 | 463.6 | 539.8 | 412.8 | 463.6 | 536.7 | 412.8 | 463.6 | 565.2 | 412.8 | 457.2 | 574.8 | 406.4 | 457.2 | 641.1 | - | - | - |

| 18 | 474.7 | 527.0 | 549.4 | 474.7 | 527.0 | 596.9 | 469.9 | 527.0 | 593.8 | 469.9 | 527.0 | 612.9 | 463.6 | 520.7 | 638.3 | 463.6 | 520.7 | 704.8 | - | - | - |

| 20 | 525.5 | 577.8 | 606.6 | 525.5 | 577.8 | 654.0 | 520.7 | 577.8 | 647.7 | 520.7 | 577.8 | 682.8 | 520.7 | 571.5 | 698.5 | 514.4 | 571.5 | 755.6 | - | - | - |

| 24 | 628.6 | 685.8 | 717.6 | 628.6 | 685.8 | 774.7 | 628.6 | 685.8 | 768.4 | 628.6 | 685.8 | 790.7 | 628.6 | 679.4 | 838.2 | 616.0 | 679.4 | 901.7 | - | - | - |

High strength graphite gasket

High strength graphite gasket

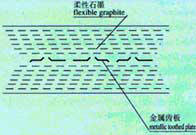

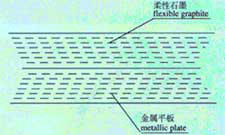

1.Structure

The high-strength gasket is composed of pressed metal sheet

and flexible graphite grain after pressing and cutting.

2.Performance and Features

1.Applicable to wide range of conditions. high and low

temperature resistance, corrosion resistance, and radiation

resistance. Applicable to high pressure location.

2.Normal finishing requirement for flange surface which

contact gasket.

3.Perfect sealing performance.

4.Low pre-tightening stress, not adhere on flange sealing

surface, easy installation, and low labour force required.

3.Scope of Application 1.Working temperature:-2000C-6000C

1.Working temperature:-2000C-6000C

2.Working pressure:6.4-10.0MPa

3.Min.Pre-tightening specific pressure:y =30MPa

4.Gasket cofficient:m=2

5.Max.machinable size:~2100mm