Pure / Filled PTFE / PTFE Products

PTFE Rods

|

PTFE Sheets

|

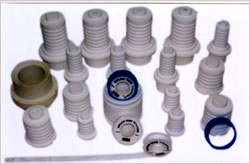

Moulded & Machined Finished Products It is often more efficient to use moulded semi-finished products to avoid excessive machining of relatively expensive materials and also to reduce machining labour and time.

The tooling costs are generally very low.

Moulded & Machined Finished Products It is often more efficient to use moulded semi-finished products to avoid excessive machining of relatively expensive materials and also to reduce machining labour and time.

The tooling costs are generally very low.

PTFE COATED FIBRE GLASS FABRIC BELTS

V.DIPESH KUMAR & CO. Offers a comprehensive range of advanced performance belts having all inbuilt properties of basic material like :

- Dimensionally stability

- Temp. resistance-50oC to + 260oC

- Light weight

- Non stick surface easy to clean

- Good heat transfer, Energy saving

- Chemically inert

SPLICES :

SPLICES :

We offer all the standard splices to assure the best performance and accurate tracking. Basic types of splices are :

- Heat Sealed Overlap

- Heat Sealed Butt

- Fabric Pin Splice

- S .S. Alligator

- Peek Spiral

PTFE RODS AND TUBES

PTFE RODS AND TUBES

PTFE (Polytetrafluoroethylene) ram extruded rods are available in standard meter lengths and in diameter ranging from 6 mm to 100 mm. PTFE compression moulded rods available from 12 mm diameter to 300 mm diameter in 300 mm diameter.

PTFE ram extruded tubes are available in outer diameter size ranging from 25 mm to 150 mm with wall thickness 3 mm and up. PTFE compression moulded tubes are available from 20 mm outer diameter to 300 mm with wall thickness 5 mm and up.

We Mould Ptfe Products for Better Tomorrow

PTFE (Ptfe) Coated Fibre Glass Fabrics,

Adhesive Tapes and Belts

Physical Properties :

| Property | Unit | Test Method | Pure PTFE | 25% Glass Filled PTFE |

25% Carbon filled PTFE |

60% Bronze Filled PTFE |

| 1. Density | gm/cc | ASTM D-792 | 2.1-2.2 | 2.25 | 2.14 | 3.8 |

| 2. Tensile strength | kgf/cm2 | ASTM D-638 | 210-350 | 125-200 | 120-155 | 105-140 |

| 3. Elongation at & nbsp; & nbsp; & nbsp; Break |

% | ASTM D-638 | 250-400 | 200-300 | 100-150 | 80-160 |

| 4.Compressive & nbsp; & ;nbsp; strength |

kgf/cm2 | ASTM D-695 | 40-50 | 75-85 | 75-85 | 115-125 |

| 5.Compressive & nbsp; & ;nbsp; modulus |

kgf/cm2 | & nbsp; | 4000 | 7000 | 8400 | 8800 |

| 6. Deformation | % | ASTM D-621 | & nbsp; | & nbsp; | & nbsp; | & nbsp; |

| A. 2 Hrs.230C, & nbsp; & nbsp;& nbsp; 140 kg/cm2 B. 24 Hrs.230C, & nbsp; & nbsp;& nbsp; 140 kg/cm2 C. Permanent |

& nbsp; & nbsp; | & nbsp; | 12 & nbsp; 15 & nbsp; 8 |

9 & nbsp; 11 & nbsp; 7 |

4 & nbsp; 5 & nbsp; 2.5 |

4 & nbsp; 5 & nbsp; 2.5 |

| D. 2 Hrs.1500C, & nbsp; & nbsp; & nbsp; 200 kg/cm2 |

& nbsp; | & nbsp; | 50 | 50 | 33 | 40 |

| 7.Flexural & nbsp; & nbsp; Modulus |

kgf/cm2 | ASTM D-790 | 57 | 42 | 96 | 80 |

| 8. Flexural & nbsp; & nbsp;& nbsp; Modulus |

kgf/cm2 | ASTM D-790 | 3500-6300 | 16700 | 11900 | 13800 |

| 9.Impact strength | cm kg cm2 |

ASTM D-256 |

& nbsp; | & nbsp; | & nbsp; | & nbsp; & nbsp; & nbsp; |

| A. -200C B. +200C |

& nbsp; | & nbsp; | 9 15 |

9.5 11 |

7.5 10 |

11 10 |

| 10.Hardness | Scale D | Shore | 60-65 | 70-75 | 70-75 | 70-75 |

| 11. Coefficient of & nbsp ;& nbsp ;& nbsp; & nbsp; & nbsp; friction |

& nbsp; | & nbsp; & nbsp; | & nbsp; |

& nbsp; | & nbsp; | & nbsp; |

| A. Dynamic P-7 & nbsp; & nbsp; & nbsp; kg/cm2 & nbsp; & nbsp; & nbsp; & nbsp; V-0.5 m/sec |

& nbsp; | & nbsp; | 0.06 | 0.5-0.54 | 0.31-0.37 | 0.12-0.17 |

| B. Static P-35 kg/cm2 | & nbsp; | & nbsp; | 0.05-0.08 | 1-0.13 | 0.09-0.11 | 0.08-0.1 |

| 12.Water Absorption | % | ASTM D-570 |

0 | 0.013 | 0 | 0 |

| 13.Heat Resistance | 0C | & nbsp; | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 |

| 14.Thermal Conductivity | 10-4 cal cm.S0C | cenco Fitch |

6 | 9 | 13 | 19 |

| 15.Linear Thermal   ;& nbsp; & nbsp; expansion |

% | ASTM D-696 |

Axial-Radial | Axial-Radial | Axial-Radial | Axial-Radial |

| A. 30-1500C | & nbsp; | & nbsp; | 1.5& nbsp; & nbsp; & nbsp; & nbsp; 1.5 | 1.5& nbsp; & nbsp; & nbsp; & nbsp; 0.7 | 1.2& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; 1 | 1.1& nbsp; & nbsp; & nbsp; 0.9 |

| B. 30-2000C | & nbsp; | & nbsp; | 2.4& nbsp; & nbsp; & nbsp; & nbsp; 2.3 | 2.2& nbsp; & nbsp; & nbsp; & nbsp; 1.0 | 1.9& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; 1.5 | 1.8& nbsp; & nbsp; & nbsp; 1.5 |

| C. 30-2500C | & nbsp; | & nbsp; | 3.4& nbsp; & nbsp; & nbsp; & nbsp; 3.6 | 3.2& nbsp; & nbsp; & nbsp; 1.4 | 2.7 & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; 2.4 | 2.5 & nbsp; & nbsp; & nbsp; 2.2 |

| 16.Dielectric Strength | kv mm | ASTM D-149 |

24 | 12 | 2 | Conductive |

| 17. Volume Resistivity | ohm cm | ASTM D-257 |

1018 | 1015 | 104 | 107 |

| 18. Surface Resistivity | ohm | ASTM D-258 |

1015 | 1015 | 107 | 109 |

| 19. Chemical & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; Resistance |

PTFE is chemically inert & unaffected by all

known chemicals except molten or

dissolved alkali metals-Sodium,

Potassium, Rubidium, Cesium, Francium & Fluorine Gas. certain fluorine compounds & complexes at elevated temperatures. Filled PTFE has interior chemical resistance because of the presence of the particular filler. |

|||||

PTFE RODS, BUSHES, TUBES & PARTS

Expanded PTFE Joint Sealant :

Expanded PTFE Joint Sealant :

Service Limits

ph range: 0-14

Temperature Limits: -260~ + 260 ℃(-500/+500°F)

Pressure Limit: 20Mpa (or 2900 psi; or 200kgf/cm2)

Physical Properties

Material: 100% PTFE, soft and excellent elasticity.

Density: 0.7~0.8g./cm3 (43~49.5lbs./cu. ft.3)

Elongation: 20%

Matrix Tensile Strength: 30Mpa (4260 psi)

Creep Relaxation (ASTM F38): 51%

Sealablity (ASTM F 37A): 0.1 ml/hr.

Description

Expanded PTFE joint tape is a multi-purpose gasket tape manufactured from 100% expanded PTFE fluorocarbon material, supplied as a continuous low density tape with a self-adhesive backing strip. It is soft and spongy, permitting it to conform easily to all surface irregularities and to compress to a thin ribbon under pressure.

Application

Expanded PTFE joint tape is recommended as a gasket tape in steel, glass-lined, PVC and fiberglass pipe flanges, fume ducts, concrete lids, heat exchangers, fiber glass reinforced plastic vessels, pump housing flanges, steam vessel flanges, manhole and manhole covers, ceramic joints, ventilation ducts, hydraulic and pneumatic systems, water supply systems and turbine cases.

Expanded PTFE joint tape is recommended as a gasket tape in steel, glass-lined, PVC and fiberglass pipe flanges, fume ducts, concrete lids, heat exchangers, fiber glass reinforced plastic vessels, pump housing flanges, steam vessel flanges, manhole and manhole covers, ceramic joints, ventilation ducts, hydraulic and pneumatic systems, water supply systems and turbine cases.

Chemical Resistance

Because Expanded PTFE joint tape is manufactured from 100% PTFE, it is an inert material which can be used in many applications against corrosive environments, except molten alkali metals and elemental fluorine. 24B will not contaminate media and can be used in food and drug equipment applications.