Established in the year 1995, Shree Polymers, is amongst the leading names engaged in manufacturing and supplying a wide range of plastic molding components, plastic injection molding components. Being an ISO 9001:2008 certified organization; we solely aim to offer flawless range to our clients by using high grade raw material and advanced technology that reflect our goal to be recognized by our customers as their number one suppliers. Our entire is widely acknowledged for its attributes like robust design, high efficiency and long service life. These plastic molded components are offered to meet the varied requirements of automotive, electrical and electronic and packaging industries. Broad-based expertise, full-service capabilities and a track record for solving complex challenges set us apart in the highly competitive industry. Moreover, our sister concern M/S Shree Plastics and M/S Precision Industries supports us to deliver bulk orders with ease. Our manufacturing units are facilitated with all the requisite machines and tools that are manned by our highly qualified team of experts. Our manufacturing unit is equipped with vertical and horizontal injection molding machine of 15 to 200 ton capacity and other sophisticated machines that allow us to undertake the production of the products with ease and precision.

In addition, under the able guidance of our owner, Mr. Rupesh Garg, we have acquired a reputed position in the domestic market. He has always motivated and has inspired us to follow ethical business practices and commitment to quality. We have been able to garner some of the prominent names such as S.M Auto Pvt. Ltd. (Pune), IFB Automotive Pvt. Ltd. (Bangalore), Carraro India Ltd. (Pune) and Turbo Gear Pvt. Ltd. (Pune).

Certification Name: International Organization for Standardization

Certification Type: ISO 9001:2008 validity October 26, 2012

“The prime motive at SHREE POLYMERS is client's satisfaction. We manufacture products as per the specifications of customers and deliver the finished goods on time. This has helped in gaining trustworthy of customer relationship. We consistently upgrade our range of products to keep pace with the ever changing technology that has earned us a strong repute and foothold in the market.”

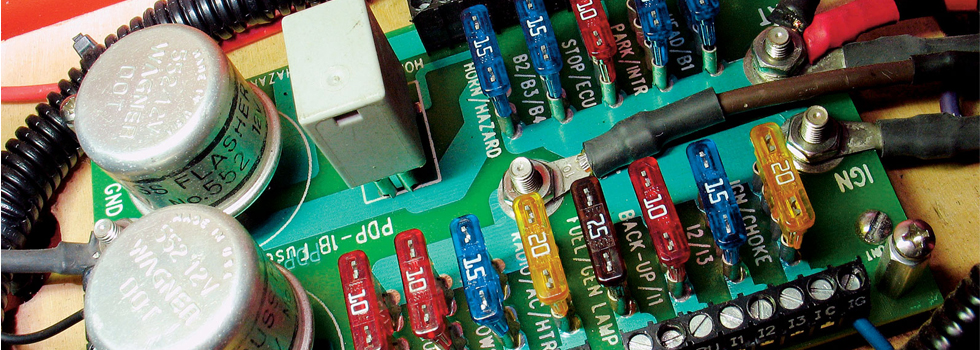

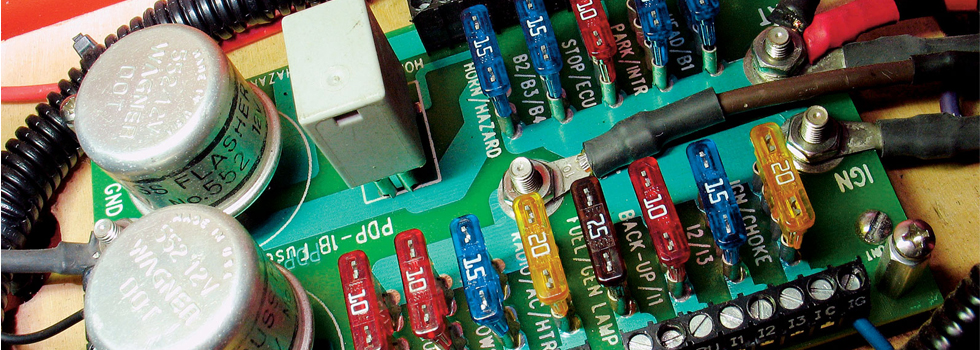

We are engaged in manufacturing and supplying a wide range of plastic injection molding industrial components that is manufactured using high grade raw material that is procured from reliable vendors. Our range includes Plastic Bobbins, Automobile Spare Parts, Insert Molding Parts and Electrical and Electronic Parts. Apart from these, we are also offering Packaging Products, Industrial Caps, Threaded Plug and Plastic Parts. These are widely used in various industries such as automotive, electrical and electronic and packaging. Available in various specifications, these can be easily customized as per the definite needs of our clients. Our range is best in quality and is highly appreciated by our clients for high performance and durability. Our range encompasses the following:

Some of the salient features of our range include:

Dimensionally accurate

Robust design

High efficiency

Abrasion resistance

Low maintenance

Resistant to temperature variations

Long service life

We endeavor to offer wide range of plastic injection molding industrial component that is extensively used in various industries that are as follows:

To meet the varied requirements of our esteemed clients, we offer them with the customized range of plastic injection molding industrial components that is designed and manufactured as per the exact specifications and requirements provided by our clients. We have been able to achieve a wide clientele in the domestic market due to our efforts in offering customized range to our clients. We offer customization on certain parameters, these include:

Raw material

Dimensions

Design

Size

We are an ISO 9001-2008 certified company, thus we lay immense stress on quality and believe in offering finest range of plastic injection molding industrial components to our clients. Our team of quality controllers closely examines the complete manufacturing process to avoid any kind of defects in the final products. The quality control procedures start right from the time of procurement of raw material till the final shipment of the components. Before dispatching our range of plastic molded components to the clients’ end, our each product is individually tested on certain parameters so that only flawless range leaves our premises. We test our entire range on the following parameters:

Performance

Dimensional accuracy

Maintenance

Durability

We are well supported by a highly competent team of workforce that enables us to meet the specific requirements of our clients proficiently. Our team is supervised by highly experienced professionals, who have sound experience of the industry and undertake all the consignments to carry out well on time. Our dexterous team includes:

Mechanical engineers

Designers

Material and processing experts

Quality controllers

R&D experts

Marketing and sales executive

The team expert designers and engineers are well equipped with the latest software, which helps us to design with accuracy & perfection. Our team of personnel keep themselves abreast with technological advancements and thus it is capable of dealing with specific requirements of our clients. They work in close coordination with each other so as to offer complete satisfaction to the end user.

All our endeavors lay in offering quality plastic injection molding industrial components. We make use of high grade raw material that is procured from reputed vendors in our manufacturing process to ensure quality of the end products. These are thoroughly tested by our team of quality controllers. Following are the raw material that we use:

Polyethylene (polyethene) with Blended and non-blended

Polypropylene with Blended and non-blended

Polystyrene with Blended and non-blended

Styrene acrylonitrile: SAN

Acrylonitrile butadiene styrene: ABS

Engineering Plastics with blended and non-blended

Blended raw material: This contains abrasives like, glass-fiber, talk-feel, UV-stabilizer, EPDM, FR-resistance and weather-resistance

We are backed by two well-developed manufacturing units that are spread over a vast area 2500 square feet with an adequate installed capacity. Our organization is equipped with various kinds of vertical and horizontal injection molding Machine of 15 to 200 tons capacity. It is segregated into various units and shops so as to carry out hassle free business activities:

Manufacturing unit

Quality testing laboratory

In-house testing unit

Machine shop

Packaging unit

Research and development department

Some of the modern machines that are installed at our manufacturing unit include:

Cutting

Drilling

Lathe

Vertical and horizontal injection molding Machine of 15 to 200 ton capacity

Special purpose machines

Furthermore, our in-house design unit is equipped with latest CAD/CAM facility that allows us to design our plastic injection molding industrial components with accuracy & perfection. In addition, we also pay greater emphasis on the regular up-gradation and modernization of our production units that enables us to maintain pace with the changing technologies, emerging trends and end product requirements.

Our organization is bestowed with a well-developed R&D unit, which carry out various research works towards designing and developing new plastic molded components of better quality. This department is equipped with all the latest tools and instruments that assist us in analyzing the most feasible development in the industry. Our research experts endeavor to invent new manufacturing process, which helps in reducing the manufacturing cost of our wide range of plastic injection molding industrial components. Our research and development department conducts research on the following factors:

Manufacturing process

Technology used

Raw material

Design

Further, they also help us to understand the market trends, so that we can provide satisfactory products to our clients as per their specifications.

Since our establishment, we have been serving our clients with our wide range of plastic injection molding industrial components. Our well-developed infrastructure is equipped with hi-tech machinery that assists to produce precision-engineered range of components. Further, our ability to deliver these components in bulk amount coupled with timely shipment of finished products has enabled us to establish cordial relations with clients spread across the country. Due to our ethical business policies and wide distribution network, well established names of the industry prefers to work with us. Some of them are as follows:

S.M Auto Pvt. Ltd. (Pune)

Positive Packaging Ind. Pvt. Ltd. (Khopoli)

Suniti Electricals (Pune)

Turbo Gear Pvt. Ltd. (Pune)

Carraro India Ltd. (Pune)

Flash Electronic (IND.) Pvt. Ltd. (Pune)

Supreme Industries (Khopoli)

IFB Automotive Pvt. Ltd. (Bangalore)

Diversified