Digital Flowmeter

EXAIR’s Digital Flowmeter is the easy way to monitor compressed air consumption and waste! The digital display shows the exact amount of compressed air being used downstream. This makes it possible to save thousands of dollars per year in compressed air waste – helping to identify costly leaks or inefficient air products. Many companies install the Digital Flowmeter on each major leg of their air distribution system to constantly monitor and reduce compressed air usage.

EXAIR’s Digital Flowmeter is the easy way to monitor compressed air consumption and waste! The digital display shows the exact amount of compressed air being used downstream. This makes it possible to save thousands of dollars per year in compressed air waste – helping to identify costly leaks or inefficient air products. Many companies install the Digital Flowmeter on each major leg of their air distribution system to constantly monitor and reduce compressed air usage.

Advantages

- Easy to install

- Summing Remote Display And Data logger Available

- No Moving Parts

- Sensitive At Low Flows

- No Calibration Or Setup required

- Includes All Components For Installation

- Model From 1/2" to 4 Schedule 40 Iron Pipe in Stock

- Model Are Available For Sizes 1/2" to 6" in Iron Pipe

- Model Are Available For Sizes 3/4" to 6" in Copper Pipe

The Ultrasonic Leak Detector (ULD) is a hand-held, high quality instrument that can locate costly leaks in a compressed air system. A person using the ULD need only aim it in the direction of a suspected leak. When a leak is present, an audible tone can be heard with the use of the headphones, and the LED display will light. Testing the various unions, pipes, valves and fittings of a complete installation can be done quickly and effectively at distances up to 20' (6.1m) away!

The Ultrasonic Leak Detector (ULD) is a hand-held, high quality instrument that can locate costly leaks in a compressed air system. A person using the ULD need only aim it in the direction of a suspected leak. When a leak is present, an audible tone can be heard with the use of the headphones, and the LED display will light. Testing the various unions, pipes, valves and fittings of a complete installation can be done quickly and effectively at distances up to 20' (6.1m) away!

EXAIR’s EFC™ is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations. The EFC combines a photo electric sensor with a timing control that limits compressed air use by turning it off when no part is present. The timing control permits easy tuning to the application requirements while providing flexibility in sensing distance. The EFC also has eight programmable on and off modes.

EXAIR’s EFC™ is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations. The EFC combines a photo electric sensor with a timing control that limits compressed air use by turning it off when no part is present. The timing control permits easy tuning to the application requirements while providing flexibility in sensing distance. The EFC also has eight programmable on and off modes.

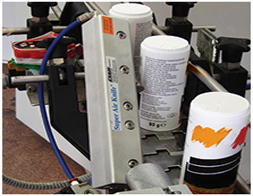

A simple solution to reduce excessive air consumption and noise levels on compressed air blowoff operation. EXAIR Air Nozzles and Jets produce outlet flows up to 25 times compressed air consumption using a small amount of compressed air as the power source. Many power companies now provide attractive rebates to plants who switch to engineered Super Air Nozzles. Air savings, compared to open copper tubes or pipes commonly used for blowoff, can be as high as 80%. Less compressed air means less noise. The typical noise level reduction is 10 dBA. All EXAIR Air Nozzles and Jets meet Occuptional Safety and Health Administration (OSHA) maximum dead ended pressure and sound level exposure requirements and carry the CE mark.

A simple solution to reduce excessive air consumption and noise levels on compressed air blowoff operation. EXAIR Air Nozzles and Jets produce outlet flows up to 25 times compressed air consumption using a small amount of compressed air as the power source. Many power companies now provide attractive rebates to plants who switch to engineered Super Air Nozzles. Air savings, compared to open copper tubes or pipes commonly used for blowoff, can be as high as 80%. Less compressed air means less noise. The typical noise level reduction is 10 dBA. All EXAIR Air Nozzles and Jets meet Occuptional Safety and Health Administration (OSHA) maximum dead ended pressure and sound level exposure requirements and carry the CE mark.

Blowoff, Clean,Dry and Cool with Less Noise and Air Consumption

Blowoff, Clean,Dry and Cool with Less Noise and Air Consumption

Advantages

Advantages

Vent,Exhaust, Cool, Dry and Clean- with No Moving Parts

Vent,Exhaust, Cool, Dry and Clean- with No Moving Parts

.jpg)

Blowoff, Dry, Clean and Cool Pipe, Cable, Extruded Shapes and Hose

Blowoff, Dry, Clean and Cool Pipe, Cable, Extruded Shapes and Hose

Cold Air for Industrial Spot Cooling Problems

Cold Air for Industrial Spot Cooling Problems

Safety Air Guns use Engineered Air Nozzles for High Performance

Safety Air Guns use Engineered Air Nozzles for High Performance

that provides superior performance by entraining large volumes of surrounding air. Safe operation is assured along with low air consumption and noise levels. Airflow that exists the nozzle can not be blocked as required by OSHA stnadard 1910.242(b)

that provides superior performance by entraining large volumes of surrounding air. Safe operation is assured along with low air consumption and noise levels. Airflow that exists the nozzle can not be blocked as required by OSHA stnadard 1910.242(b)

Cool machining operations with Clean, Cold Air

Cool machining operations with Clean, Cold Air Cool and Purge NEMA 12,4 and 4X Electrical Control Panels

Cool and Purge NEMA 12,4 and 4X Electrical Control Panels

All Stainless Steel Construction for Durability and Corrosion Resistance

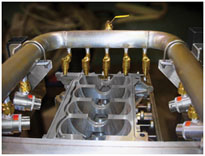

EXAIR's atomizing spray nozzles atmoize fluids(most commonly water) in a range of spray patterns for a variety of uses. They combine liquid and compressed air to create a mist of atomized liquid that can be easily adjusted to meet the needs of your application.

All Stainless Steel Construction for Durability and Corrosion Resistance

EXAIR's atomizing spray nozzles atmoize fluids(most commonly water) in a range of spray patterns for a variety of uses. They combine liquid and compressed air to create a mist of atomized liquid that can be easily adjusted to meet the needs of your application. Reliable Vacuums for Chip Removal, Liquid Transfer and Cleaning

Reliable Vacuums for Chip Removal, Liquid Transfer and Cleaning Eliminate Static Electricity, Dust and Shock Hazard

Eliminate Static Electricity, Dust and Shock Hazard