About Us

We are manufacturers of Welding Filler Wires, Stainless Steel Wires, Mild and Alloy Steel Wires and Allied Wire Products. We operate in the Western part of India with the manufacturing setup at Satara which is well connected by road and rail with the nearest port, Mumbai at a distance of approximately 300kms. The company was promoted in the year 1990 to manufacture CO2 Welding wires. We started commercial production in the year 1993 in a small way and are presently having installed capacities of about 1800MTPA of Alloy Steel, Mild Steel and Copper Coated MIG Wires ranging from diameters 0.80mm to 5.00mm. Right from inception, Amar Wires has enjoyed a good reputation and sells its products directly to industrial consumers, mostly in the Automobile sector, as well as through dealer network. Our customers include all major automobile ancillaries of reputed two wheeler and four wheeler manufacturers. With a further urge towards exponential growth and in order to keep pace with the growing competition, we have diversified into new products in the form of Stainless Steel wires. We have installed a 3000MTPA capacity plant to manufacture Stainless Steel wires in various grades and ranging from diameters 0.80mm to 5.00mm and as per customer requirement. The product range in Stainless Steel wires includes Spring Wire, Cold Heading Quality wire, Annealed Soft Wire, Electro-polishing quality wire, wires suitable for kitchen applications, Welding Electrodes (MIG and TIG). This will take our overall production levels to 5000MTPA with estimated revenues of INR 900 million. The workforce includes experienced personnel at all levels either employed or trained in-house over the years and is well equipped to achieve the expected growth rate. We strive to exceed the expectations of those who rely on us, build an everlasting relationship with our customers, suppliers, employees and the society thereby assuring for a better future, a better tomorrow.

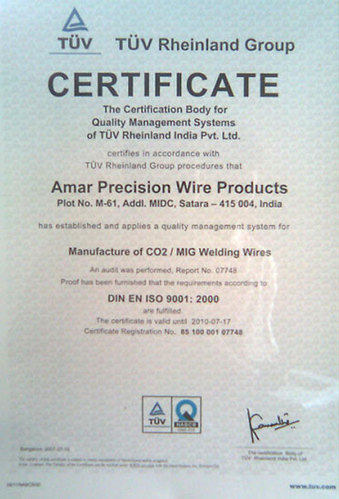

Quality Policy / Processes

To make manufacturing the primary marketing tool through excellence in product quality, achieving maintainability of quality, continual improvement of systems, and responsiveness and flexibility towards customers demands with a view to achieving total customer satisfaction.

Keeping in view the widening market and desire to enhance the quality of product and our services to the entire satisfaction of the customer, the unit has implemented ISO-9000 quality standards since September 1997 and presently continues to be accredited by TUV Rheinland / Berlin - Brandenburg, to ISO -9001-2000 quality system.