Call Us : +91-8087930425

Email id : Info@ashokasystem.com

Call Us : +91-8087930425

Email id : Info@ashokasystem.com

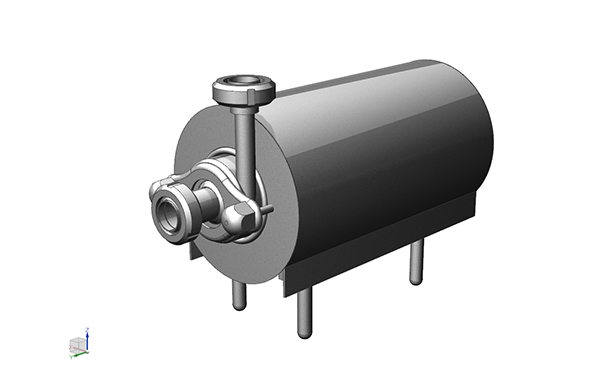

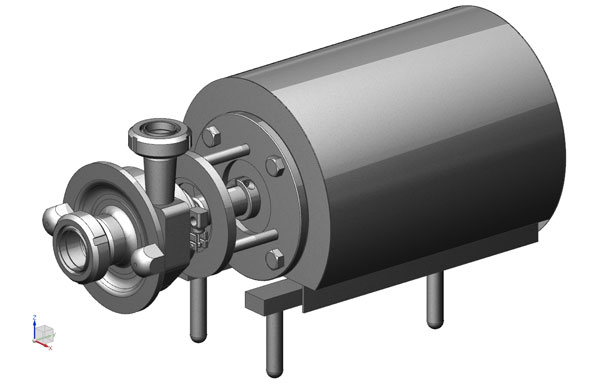

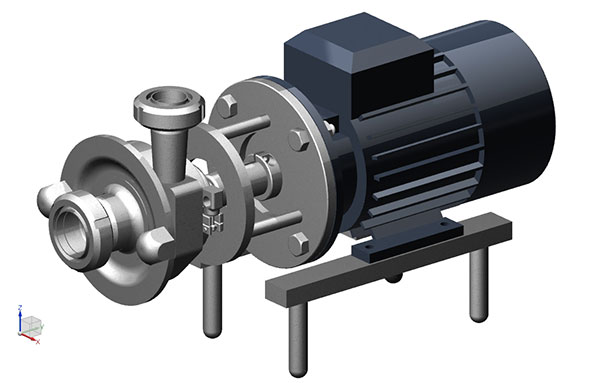

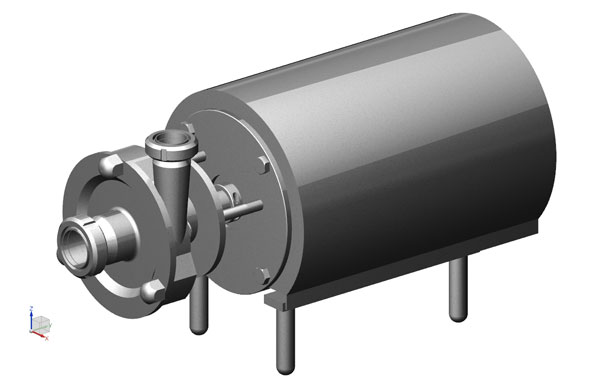

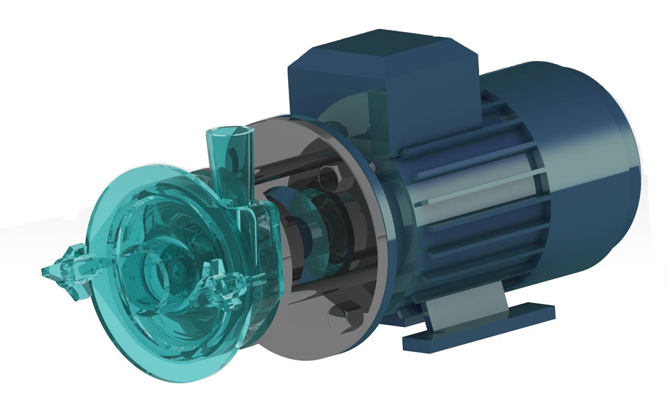

Owing to its excellent quality and high suction capacity, our range is widely used in various industrial applications such as dairy, beverage, winery, pharmacy, distilleries & service Industry. It has low NPSH These pumps provide an unusual protection against highly corrosive chemicals. The solid molded casing and impeller ensure a smooth running pump for long life and minimum wear. All pumps, shafts are fitted with sleeves of different materials compatible with the liquid handle.

Pump offers wall thickness of 6 to 12 mm provided the ideal basis for problem operations. It has double mechanical shaft seal & hence covers almost all type of liquid transfer applications under normal as well as in vacuum conditions It has unique features like power consumption, high functionality and excellent suction performance. The fluids pumped may contain air or other gas be homogeneous or contain additions & viscosity up to 1,200 mpas, further low npsh level also permit us to use under unfavorable intake conditions.

We supply mostly Ashoka system related mechanical seal.

We offer high quality range of pump seals, which confirm to the highest standards of quality

Manufactured from quality raw material these are in high demand by our client’s spread across the nation.

We also meet customized requirement for our clients benefit.

It has the capacity up to 8,00,000 liters and lifting head up to 100 meters.

Owing to its excellent quality and high suction capacity, our range is widely used in various industrial applications such as dairy, beverage, winery, pharmacy, distilleries & service Industry.

It has low NPSH

These pumps provide an unusual protection against highly corrosive chemicals.

The solid molded casing and impeller ensure a smooth running pump for long life and minimum wear. All pumps, shafts are fitted with sleeves of different materials compatible with the liquid handled

These hygienically cleaned process pumps have the capacity up to 8, 00,000 liters and lifting head upto100 meters.

Excellent suction performance makes it possible to use these pumps even under unfavorable inlet conditions (Low NPSH).

These are widely used in various industries such as dairy, beverage, winery, pharmacy, distilleries & service Industry.

Pore free pumps without cavities or blow holes

Low energy consumption

High speed

Low maintenance cost

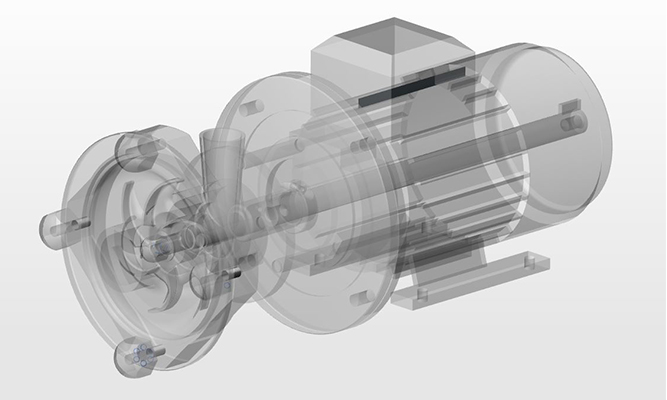

Our pumps superior performance & high energy efficiency is partly a result of their internal geometry which ensures excellent flow characteristics.As pumps are open impeller with streamlined flow path & maintenance time & effort. Designed with front loading seal. The material for the pump is SS 304 / SS 316.

Our pumps superior performance & high energy efficiency is partly a result of their internal geometry which ensures excellent flow characteristics.As pumps are open impeller with streamlined flow path & maintenance time & effort. Designed with front loading seal. The material for the pump is SS 304 / SS 316.

The parts of the pump are made by investment casting by this method we get high quality & precision work.The flow path has been designed with gradually increasing cross-section towards the pump discharge. In conjunction with open impeller & variable pitched vanes.This provides the ideal centrifugal flow path.

.jpg) Ashoka system pumps are equipped with open impeller which are perfect in hygienic design. Every pump has a minimum wall thickness of 6 to 10 mm providing ideal basis for problem free operation. The fluid pump may contain additives & viscosity up to 1200 Mpas also are no problem. Low NPSH levels also permit use under unfavorable intake conditions.

Ashoka system pumps are equipped with open impeller which are perfect in hygienic design. Every pump has a minimum wall thickness of 6 to 10 mm providing ideal basis for problem free operation. The fluid pump may contain additives & viscosity up to 1200 Mpas also are no problem. Low NPSH levels also permit use under unfavorable intake conditions.

Ashoka system pumps are run with low vibration which gives high reliability & long life of mechanical seals. We provide both single acting and double acting mechanical seals. Double mechanical seals make pump suitable for operations under vacuum condition & prevent damage to the product by contamination & environmental pollution due to product emission.

Vivamus sagittis lacus vel augue laoreet rutrum faucibus dolor auctor.

: Plot No-112/13, S Block Midc, Bhosari, Pune-411 026, Maharashtra (India)

: +91-808 7930 425