Our Services

1. Producing Press Tools

Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce components at high volumes. Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging,trimming etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool etc.

2. Jijgs And Fixtures

Jigs and fixtures are special purpose tool which are used to facilitate production (machining, asslembling and inspection operations), when work piece is based on the concept of interchangeability according to which every part will be produced within an established tolerance

3. Gauges

A gauge or gage, in science and engineering, is a device used to make measurements or in order to display certain information, liketime. A wide variety of tools exist which serve such functions, ranging from simple pieces of material against which sizes can be measured to complex pieces of machinery.

4. BIW Welding Fixture

Biw welding fixtures on exhaust basis. We have expertise in designing & manufacturing of exhaust biw welding fixture.

5. BIW Checking Gauges

Biw checking gauge helps in minimizing time required for sorting of rejected parts. Each gauge passes through a strict inspection to assure the best tool is provided to the clients

6. Leak Testing Machine

Our leak testing products are designed for testing applications under pressure or vacuum, which utilizes our mass extraction technique. We manufacture a variety of complete leak test instruments with optional accessories.

7. SPM Machines

Special Purpose Machines (SPM) are those Machine which are not Available Off the Shelf. These are not Covered in Standard Manufacturing Programs. There Fore they have to be Designed & Tailor Made as Per the Customers Specific Requirements. They are also Called as Bespoke Machines

8. Sheet Metal Stampings

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

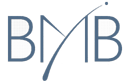

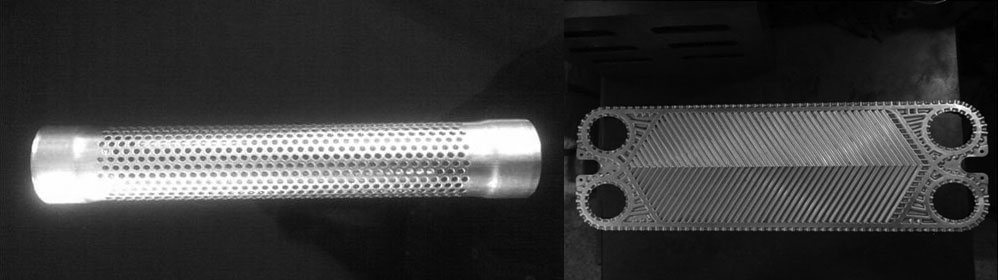

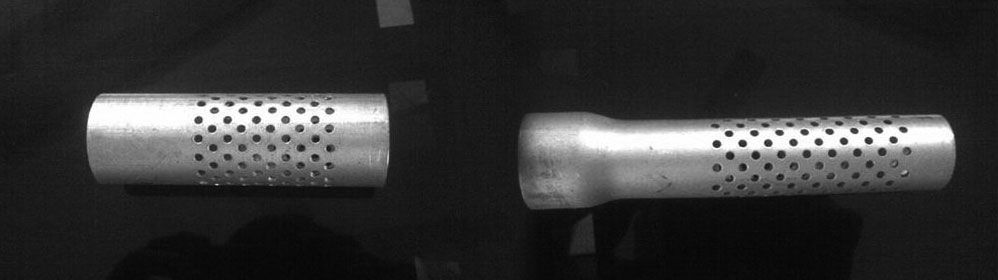

9. Exhaust Systems Sub Assy & Child Parts Manufacturing

An exhaust system is usually piping used to guide reaction exhaust gases away from a controlled combustion inside an engine orstove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Sub assembly is a unit assembled separately but designed to fit with other units in a manufactured product

10. Value Engineering

Bhakti Industries has successfully executed many value engineering for customers and there by measurable impact in cost optimization, Weight reduction, Topology optimization, Parts Optimization.