Fosroc Nitobond Ep STD

Epoxy resin concrete bonding agent

Epoxy resin concrete bonding agent

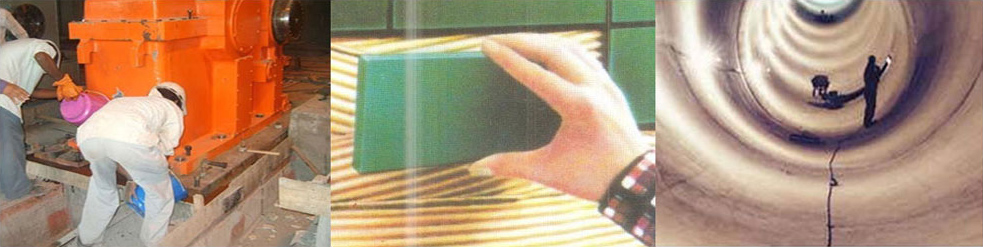

Uses

For bonding new cementitious materials to existing cementitious surfaces. For use on horizontal surfaces and on vertical surfaces where mortar or concrete can be supported by formwork. Ideal for extensions and repairs to structural concrete in buildings, loading bays, bridges, roads, bonded or granolithic floor toppings etc.

Advantages

Nitobond EP can be applied by brush.

- More overlay time: Enables to place the concrete upto 6 hrs after applying Nitobond EP, without risk of delamination

- High bond strength: Bond strength is more than the tensile strength of good quality concrete

- Barrier coat: Acts as a 'barrier coat' to the migration of chloride ions from host concrete.

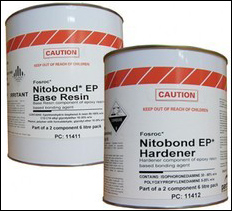

Description

Nitobond EP is based on solvent free epoxy resins containing pigments and fine fillers. It is supplied as a two part material in preweighed quantities for ready onsite mixing and use. Coloured components - white base and green hardener - provide visual evidence that adequate mixing is achieved.

Technical support

The company provides a technical advisory service supported by a team of specialists in the field.

Design criteria

Nitobond EP is designed with an overlay time of 10 hrs at 200 C, 6 hours at 30 0C making it more suitable for use where additional steel reinforcement and formwork has to be fitted or where temperature is high. The minimum application temperature for Nitobond EP is 10 0C. Consult the local Fosroc office for further information.

Specification clauses

The bonding agent shall be Nitobond EP an epoxy based two component resin system prepacked in distinct colours to give visual evidence for proper mixing. The bonding agent should remain in tacky state after application for a minimum period of 6 hours at 300C. There shall not be bond failure of the specimen when tested by slant shear method according to BS 6319 pt 4, with M30 concrete.

Application instructions

Preparation

All surfaces to be treated must be firm, dust free and clean. All laintence should be removed by etching with Reebaklens and wire-brushing. In some cases, the existing concrete must be chipped to a sound substrate. Where surfaces are contaminated with oil or grease, this should be removed by using a strong industrial detergent or organic degreaser. Surface should be washed thoroughly with water and dried before the application of Nitobond EP.

Mixing

The entire contents of the hardener can should be poured into the resin container and the two materials thoroughly mixed until a uniform colour is obtained. To facilitate application at temperatures below 10 0 C the separate components should be warmed in hot water to a maximum of 25 0 C before mixing.

Coating

Mixed Nitobond EP should be brush applied to the prepared surface. The new concrete should be placed within 6 hours at 300C to the Nitobond EP coated substrate, when it is in a tacky state.

Limitations

Nitobond EP should not be applied when the temperature is below 100 C. If any doubts arise concerning temperature or substrate conditions, consult the local Fosroc office.

Estimating

Packaging

Available in 1/2, 1 and 4 litre industrial packs.

Coverage

Approximately 2.6 m2 /litre. Actual coverage will depend upon the texture and porosity of the substrate being covered.

Storage

Shelf life

12 months if stored under normal warehouse conditions below 350 C, in unopened containers.