Duralloy Anti Wearplates

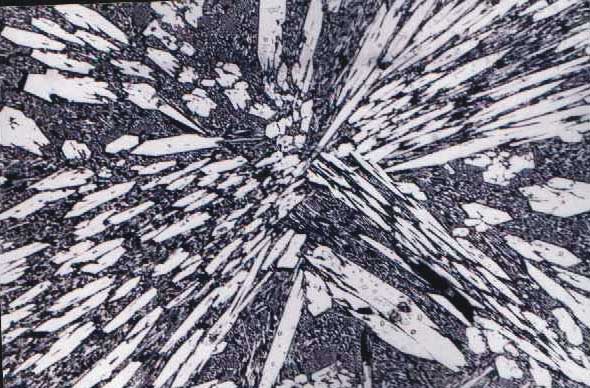

Anti-wearplate Manufacturing is a highly specialized process in which mild steel base plate is coated by simultaneous blending of alloy wires and alloy metal powders, which ensures maximum concentration and minimum dilution. The Antiwearplate provides protection to your machinery components to combat wear very effectively and economically.

The composite Anti-wearplates in which mild steel base is weld cast by chromium and other alloy carbides to achieve properties viz. severe abrasion, moderate to heavy impact and heat resistance in one single plate without sacrificing very high initial hardness.

Properties : Abrasion and Impact Resistance

Abrasion resistance of Duralloy Anti-wearplates is due to Chromium Carbides/Alloy Carbides concentration of 45% to 60% in hard overlay and impact resistance due to ductile mild steel base. High carbide / boride concentration is due to computerised weld cast process.

Minimum Bend : Radius

Hard face outside : 75 mm

Hard face inside : 75 mm

Installation

Duralloy Anti-wearplates can be welded to any existing metal structure by welding the mild steel base with low hydrogen or stainless steel electrode depending on the metal structure.

Duralloy Anti-wearplates are provided with countersunk holes or plug weld holes by a specially designed Metal Arc Disintegrator System.

Thickness

| Hard Overlay mm |

Base mm |

Total ± mm |

| 3 | 5 | 8 |

| 4 | 6 | 10 |

| 4 | 8 | 12 |

| 5 | 6 | 11 |

| 5 | 8 | 13 |

| 5 | 10 | 15 |

| 6 | 8 | 14 |

| 7 | 10 | 17 |

| 8 | 10 | 18 |

| 8 | 12 | 20 |

| 6 | 12 | 18 |

| 10 | 20 | 30 |

| 6 | 25 | 31 |

Standard Plate Size : 2800X1400 mm

Larger Plate : Made to Order

Duralloy Fused Alloy Anti-wearplates : Can be Supplied As per your drawing

Applictions :

- Power Generation

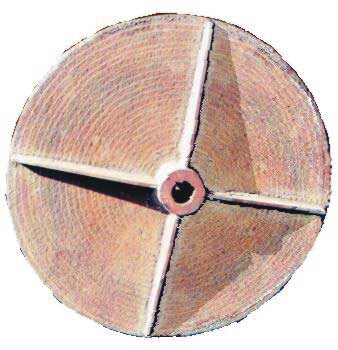

- PA/ID/FD Fan Blade Liner

- Inner Cone

- Separator Body Liner

- P.A. Fan Volute Casing

- Coal Crusher Liner

- Liners for ESP Duct

- Crusher Chute Liners

- Breaker Plates

- Vibrating Screen

- Suction Adapters

- Cement Industry

- HAZ-MAG Crusher Liner

- Hammer Mill Liners

- Atox Mill Liners

- Coal Mill Body Liners

- Air Separator Vanes

- Disagglomrator Liners

- Various Chutes

- ESP Ducts

- Mining Industry

- Dozer Blade Liners

- Dragline Bucket Liners

- Shovel Bucket Liners

- Vibrating Troughs

- Loading Chute Liners

- Gyratory Crusher Liners

- Scalping Screen

- Curved Liners for B/W Reclaimer

| Grade | Typical Properties |

| Duralloy (Standard) |

High Stress Abrassion and heavy impact use upto 450 c. Plate can be rolled to 75mm radious. |

| Duralloy H.T. |

High stress abrasion at elevated temprature from 500 c to 800 c. |

| Apart from above custom made grades can be manufactured and supplied as per the suitability of application. |

|

- Steel Industry

- BLT Distribution Chute for Blast Furnace

- Feeder Spout

- Material Gate of BTL Furnace

- Coke Oven Pusher Plate

- Coke Oven Discharge Chute

- Chute liners for Sintering Plants

- Tilting Chute Liners

- Advantages

- Lesser Maintenance of equipment.

- Substantial Decrease in breakdown.

- Higher productivity.

- Savings in power consumption.

- Increase in life of equipments/machinary.