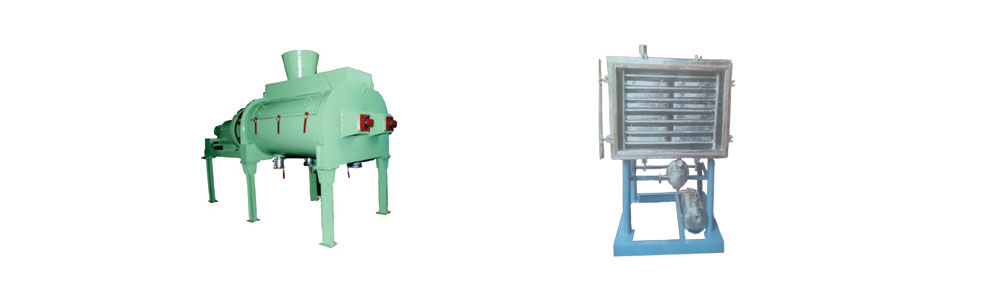

Rotary Tunnel Dryer

General Advantages

General Advantages

- Can operate either as batch type or continuous type drier. Can operate either as batch type or continuous type drier.

- Operates at low power – Maximum of 5 HP

- Drying time around 25% that of Tray Drier – Saves production time.

- Temperature can be positively controlled anywhere between 35 to 200° C

- Very economical – Material cost can be controlled as instead of a SS shell, M.S. shell with SS lining can be used.

- Totally contained system – Evaporate fumes can be directed to the desired position.

- Product can be cooled before discharging – Time saving as product can be directly sent for packing.

Uses

For free flowing non – hygroscopic powder, crystalline material, granular material, grains and any agricultural product.

Design Aspect

| Total Volume | 400 to 50,000 Ltrs. |

| Working Volume | 100 to 12,500 Ltrs. |

| Chamber Dimensions | 600 to 1500 mm. Ø x 3 to 50 Mtr. L |

| Output Speed | < = 1 RPM |

| Motor HP | 5 HP Max |

| Drying Time | 1 to 3 Hrs. (batch process) 100 Kgs. To 1000 Kgs. / Hr. (Continuous process) |

| Drying Temperature | 35 to 200° C |

| Heating | Hot water / Gas / Wood / Electric |