Hand Valve Operated Bottle Rinsing Machine

We are a reliable and well-known manufacturer and supplier of a range of Hand Valve Operated Bottle Rinsing Machines. The premium quality S.S/ M.S Soaking tank is offered to the customers on varied customized designs and specifications, as per exact customers' requirements. The S.S. Rimaing sets include a valve, bottle holder and brushing unit driven by motor. We offer these in 24/12/36 Nos. rinsing nozzle jet.

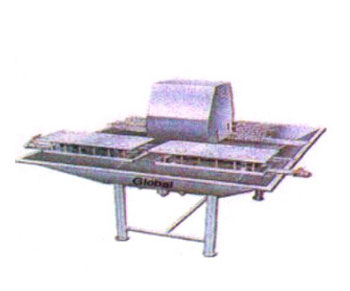

Rotary Bottle Washing Machine

We are a prominent manufacturer and supplier of a wide range of Rotary Washing machine-STD Models, These semiautomatic rotary bottle washing machines have been designed to wash and clean various size & shapes of bottles from 15 ml to 750 ml with the aid of jets and 4 cycles. The bottles are carried on a rotary platform that has abilities of completing one revolution per minute.The water jets along with main body are made of premium quality SS 304 material.

A hood covers the bottle and provides continuous water spray. In this model, a top is provided to wash the bottle outside. The machine also includes 2 stainless steel centrifugal pumps, 2 square stainless steel tanks and an electrical panel box. It requires three operators to operate the machine for bottle loading and unloading- two for loading and one for uploading. The machine rotates clockwise when viewed from the top and the driving mechanism is arranged at the bottom in an enclosed cabinet. All the contact parts are duly painted, are of of reliable SS 304 quality and can be polished to mirror finish.

Rotary Bottle Washing Machine

We are a prominent manufacturer and supplier of a wide range of Rotary Bottle Washing Machine-STD Models, These semiautomatic rotary bottle washing machines have been designed to wash and clean various size & shapes of bottles from 15 ml to 750 ml with the aid of jets and 4 cycles. The bottles are carried on a rotary platform that has abilities of completing one revolution per minute.

The water jets along with main body are made of premium quality SS 304 material. A hood covers the bottle and provides continuous water spray. In this model, a top is provided to wash the bottle outside. The machine also includes 2 stainless steel centrifugal pumps, 2 square stainless steel tanks and an electrical panel box. It requires three operators to operate the machine for bottle loading and unloading- two for loading and one for uploading. The machine rotates clockwise when viewed from the top and the driving mechanism is arranged at the bottom in an enclosed cabinet. All the contact parts are duly painted, are of of reliable SS 304 quality and can be polished to mirror finish.

Brushing Machine with Soaking Tank

We offer our customers with a range of high quality Washing Section-Brushing machines with Soaking Tanks. These have been designed and manufactured keeping in mind the varied requirements of the customers to ensure that these fulfill the varying requirements of our customers. The range is offered in a number of standard as well as customized forms in ten/eight/six/four heads, as per the customer's requirements.