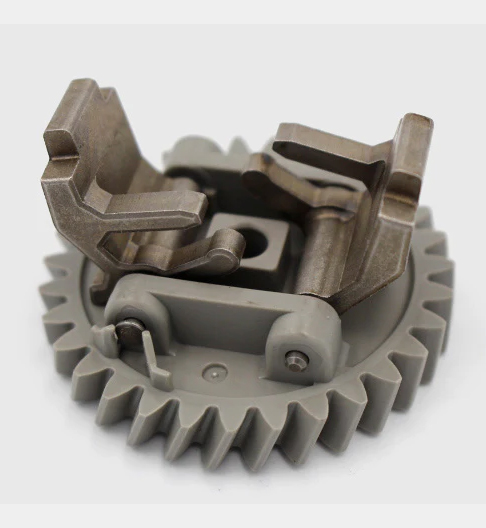

Governor Gear

Governor Gear

The governor gear typically consists of a gear and a set of fly weights that pivot in and out. The governor gear is meshed with the crankshaft, and, as the crankshaft turns, the centrifugal force of the spinning motion forces the fly weights outward. Governor gears are normally inside a small engine’s block, but there are some engines, such as the Kohler K532, that have the governor gear as an external assembly which is bolted to the engine.

As your engine runs, the governor gear is constantly spinning and forcing the fly weights outward. This, in turn, pushes on the tab of the governor cross shaft. The governor cross shaft is forced to rotate and moves the governor arm toward your carburetor to close the throttle. As the throttle closes, the RPMs slow. The governor spring, on the other hand, is always applying tension to the other end of the governor arm which is pulling the throttle open. As the throttle opens, your RPMs speed up. When the two opposing forces—centrifugal force and spring tension—are equal to each other a constant RPM is achieved.