Compressors Auxiliaries

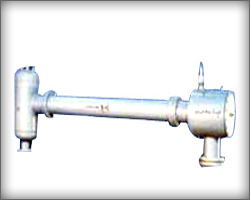

After Coolers

Our aftercoolers are effective heat exchangers used for cooling the discharge from a compressor. Using either air-cooled or water-cooled mechanism, it is an effective means of removing moisture from compressed air. By condensing the water vapor into liquid form, aftercoolres control the amount of water vapor in a compressed air system. Liquid water can cause significant damage to the equipment that uses compressed air in a distribution or process manufacturing system. An aftercooler plays vital role for proper functioning of pneumatic or air handling devices which are part of process manufacturing systems. A compressor aftercooler may be either a stand-alone unit located downstream of the compressor or integrated into the compressor itself. Fitted into a pipeline, water-cooled heat exchangers use a moisture separator and drain valve for extracting the water from the compressed air while moving through the pipe. Centrifugal force mechanism is used by it to separate out the moisture and solids from the compressed air and they exit the system through a drain. An air-cooled heat exchanger uses ambient air for cooling hot compressed air. It also uses a motor-driven fan for forcing the ambient air over the cooler, removing the heat from the compressed air.

Our aftercoolers are effective heat exchangers used for cooling the discharge from a compressor. Using either air-cooled or water-cooled mechanism, it is an effective means of removing moisture from compressed air. By condensing the water vapor into liquid form, aftercoolres control the amount of water vapor in a compressed air system. Liquid water can cause significant damage to the equipment that uses compressed air in a distribution or process manufacturing system. An aftercooler plays vital role for proper functioning of pneumatic or air handling devices which are part of process manufacturing systems. A compressor aftercooler may be either a stand-alone unit located downstream of the compressor or integrated into the compressor itself. Fitted into a pipeline, water-cooled heat exchangers use a moisture separator and drain valve for extracting the water from the compressed air while moving through the pipe. Centrifugal force mechanism is used by it to separate out the moisture and solids from the compressed air and they exit the system through a drain. An air-cooled heat exchanger uses ambient air for cooling hot compressed air. It also uses a motor-driven fan for forcing the ambient air over the cooler, removing the heat from the compressed air.

Aftercoolers are an important component in any system that uses compressed air which is very hot and may pose a fire hazard to downstream equipment. Benefits of the aftercoolers are as follows:

- ⊗ Shell & Tube Design & Water Cooled.

- ⊗ Tube bundle removable type & fixed type.

- ⊗ Vertical type & Horizontal type (version).

- ⊗ Air Flow 10 to 10,000 cfm or Higher on request.

- ⊗ Pressure up to 100 kg/cm2.

- ⊗ Built as per India & International codes.

- ⊗ Vortech aftercooler is a popular, proprietary type of air to water

- ⊗ Used in cars and trucks to reduce the temperature of forced induction air in a supercharged engine

| Payment Terms: | L/C (Letter of Credit) |

| Delivery Time: | prompt |

| Packaging Details: | as per requirement |