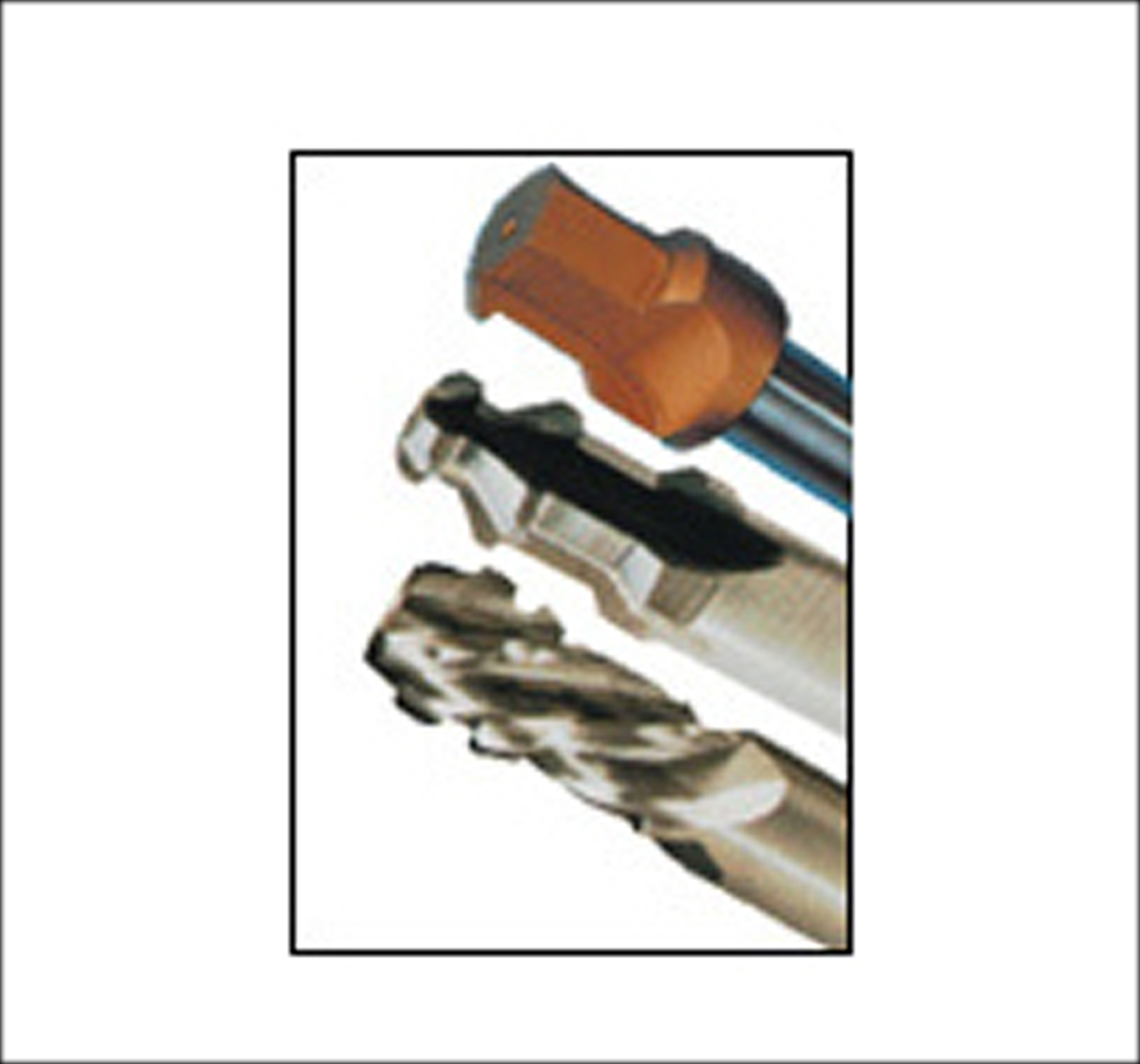

Our Products

- Solid Carbide End Mill Cutter

- Solid Carbide Ball Nose Cutter

- Solid Carbide Stub Drill

- Solid Carbide jobber Drill

- Solid Carbide Reamer

- Solid Carbide Step Drill

- Solid Carbide Drill Cum Reamer

- All Types Of Lugged Cutter

- All Types Of Brezed cutter

- Dowtel Cutter

- T Slot Cutter Carbide & Brezed

- Spl.Form Cutter Carbide & Brezed

Contact Us

Micro Tools

Contact Person

Mr. Pravin S Dhumale

Telephone: +(91)-9850030546, 8237062702

Address: Serve.No.23,Hanuman Nagar, Near Hanuman Temple, Bhagat vasti,Bhosari,Pune 411026

E-Mail- microtools1@rediff.com ,microtools1@yahoo.com

OUR PRODUCT

We offer

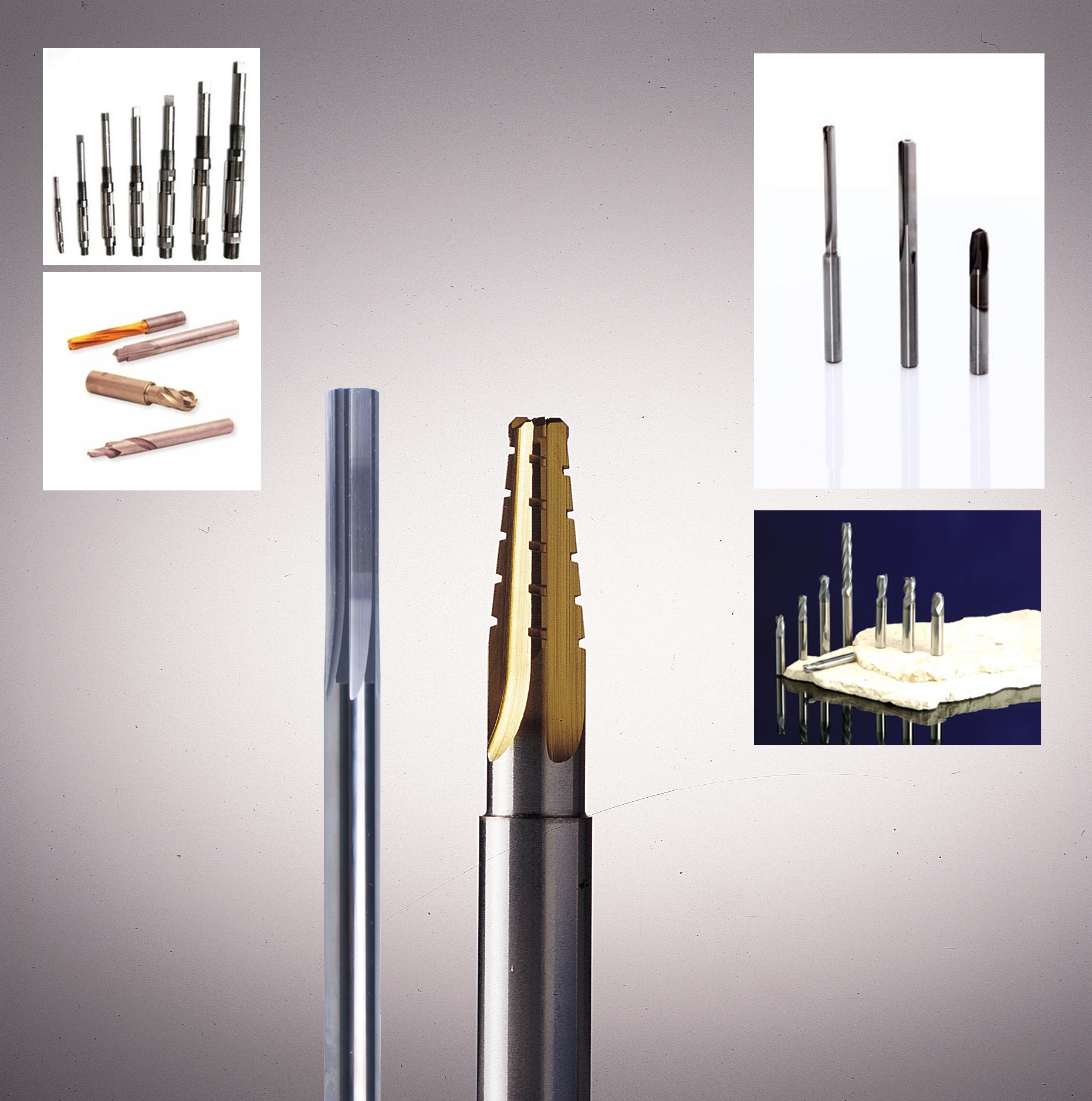

Solid Carbide End Mill Cutter

Company offers a wide variety of end mills for just about any application. From standard end mills to long, short, double end, high spiral, roughing, miniature and more...you'll find what you need right here.We offer solid carbide end mills that are trusted and relied by our valued customer. We make use of highly sophisticated 6-Axis CNC tool cutter grinding machines, which produce carbide end mill of the most superior quality. Solid carbide end mills are produced from ultra fine micro grain carbide that has high resistance towards wear and tear. And when combined with titanium nitride (TiN) and TIALN coatings, these end mills are capable for machining materials that have hardness of up to 55 HRC

Solid Carbide Ball Nose Cutter

Our comprehensive range of ball nose cutter is manufactured from qualitative carbide rods. The end of these cutters are hemispherical, which is ideal for machines with 3-dimensional contoured shapes in machining centers. They are also used to add radius at perpendicular faces to reduce stress concentrations in machines. We also customize these cutters in different coatings, rake angle and number of cutting surfaces as required by our clients.

Solid Carbide Stub Drill

Basically subland drill is two drills of different diameters that have been combined into one tool but they retain the individual characteristics and geometric properties of each other. The separate and independent flutes and margins of the subland drill ensure that their sizes and concentration between diameters is maintained throughout the life of the tool and are never affected by re-sharpening the point or step angles.

Solid Carbide jobber Drill

Solid Carbide jobber Drill is designed to give outstanding accuracy and to achieve better efficiency and cost reduction. Coolant feed drill has longer and stronger blades and their wave edges are best suited for chip mounting. They also provide excellence to the strength of the insert and are available for re-cutting, if necessary.n order to achieve highly efficient drilling function use our custom & robust designed Coolant Fed Drill. These precision industrial tools enable cost reduction availing superior functionality at such a lower rate.

Solid Carbide Reamer

We manufacture special solid carbide reamers according to industry standards and as well as in customized options, as per clients specifications. Solid carbide reamers are used to widen the holes in the metals. Mainly used in places of metalwork, solid carbide reamers is used to widen the holes in the metals and it can be used in the spindles of machine tools like drill presses etc. The special design of this reamer ensures that cutting starts simultaneously with the starting of machine.

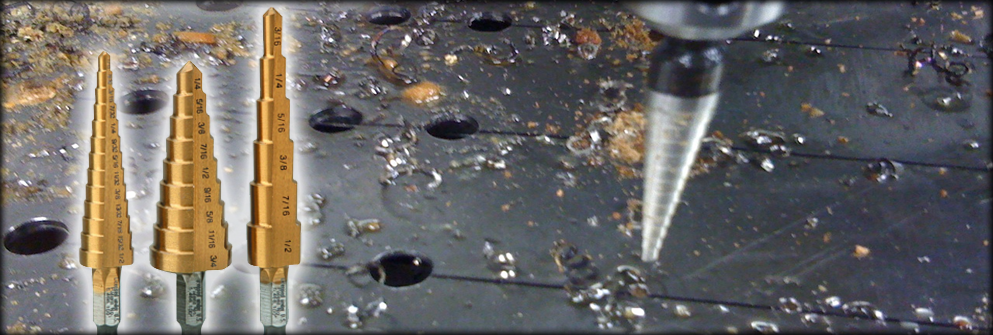

Solid Carbide Step Drill

In order to impart superior running and drilling function we have developed high precision step drill. Our step drills are known for their enhanced performance & durability in all diverse working conditions. To get good step drills, they are properly hardened and grounded to provide longer life and maximum working accuracy to the tools. Premium quality Step Drill is provided by our company to facilitate smooth drilling function. Our robust & custom designed Step Drill offer maximum working accuracy and longer life to the tools. These are offered at a best suitable rate.

Solid Carbide Drill Cum Reamer

Solid Carbide Drill and reamers are one of our most popular cutting tools. We manufacture & supply high quality steel reamers which is a popular cutting tool used in the industry. The special reamers are developed from high quality steel and has been widely acclaimed for its efficient performance under difficult conditions. It requires less maintenance, has higher durability and offer resistance from wear and tear. It is a very useful tool which makes the existing holes in metals more accurate while improving the surface finish.

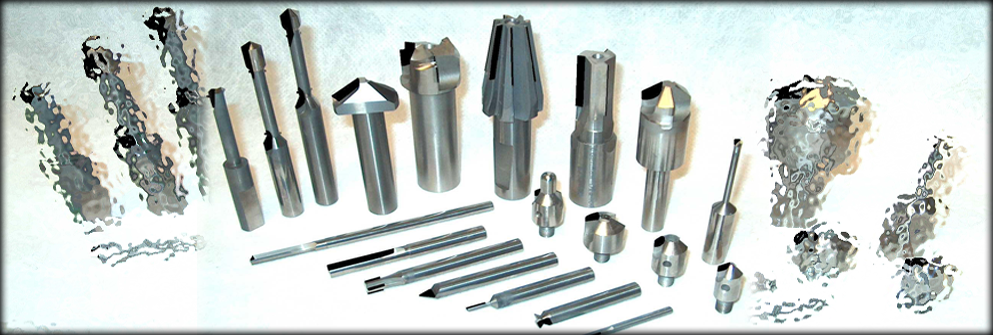

All Types Of Lugged Cutter

Reduced carbide length, reduces tool cost. Steel shank ensures tool cost saving, better tool grip resulting in higher cutting torque.This will also avoid collet damage as well as saving the machine spindle, thus increasing the machine life. The tool life can further be enhanced with various coating like TiAlN/TiN Coating etc.

All Types Of Brezed cutter

For the past many years, we have been involved in manufacturing Brazed Cutter. This tool is manufactured using high grade polycrystalline carbide materials. Our all toolkits are widely appreciated for the prime features such as corrosion resistant finish and excellent tensile strength. We have established a robust manufacturing setup to meet the high market demands for carbide tools. Our entire array is supplied through our expanded distribution network.

Dowtel Cutter

These cutters can be used in two ways. Using them like a hand held pencil sharpener, you can put accurate tenons on the tips of turnings or on rustic furniture components. The cutters can also be used with a power feed to make accurate dowelling. Most commercial dowelling is available only in nondescript wood that has been milled, not turned and is never accurately sized. Using a hand drill for power, you need only cut square stock slightly over size and use the optional square socket and adaptor to power the stock through the dowel cutter. The carbon steel blade in the plated zinc-alloy body is adjustable. Works equally well in soft, green or hardwoods. The curved blade is relatively easy to sharpen when required. Finish diameter of stock is 3/8". ©

T Slot Cutter Carbide & Brezed

Backed by a team of experts, we provide an extensive range of form cutters, punches, T-slot, Do-tail cutters to our patrons. Our range has the features of sturdy construction, corrosion resistance and durability. These are made with micro grain solid carbide products and are available in various sizes and designs. We offer tailor-made solutions for our range of T-slot as per the following basis: Required Out Side Diameter Required length Required Teeth Required Thickness Required shank dia

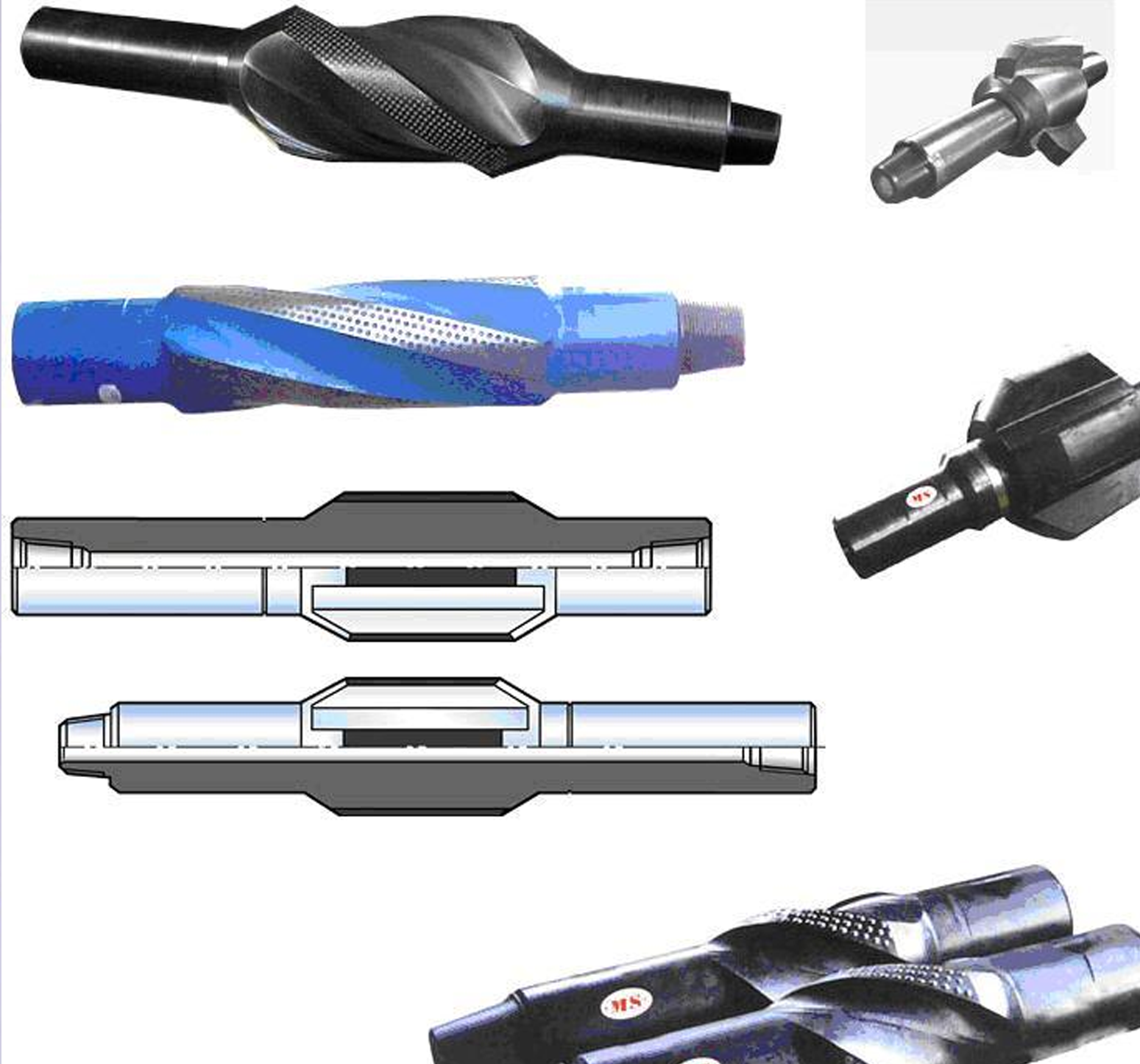

Spl.Form Cutter Carbide & Brezed

As per specific demands of our clients, We provide resharpning and relaping services for a wide range of products ( Resharpning- Relaping & Regrinding Of PCD-CBN-Solid Carbide Cutters & Form Tools ). We have modern tools and advance facilities for offering qualitative service for our range. We execute the required service on timely basis at a nominal rate and make sure that our client are totally satisfied with our service.