Gallery

Folded Thickener

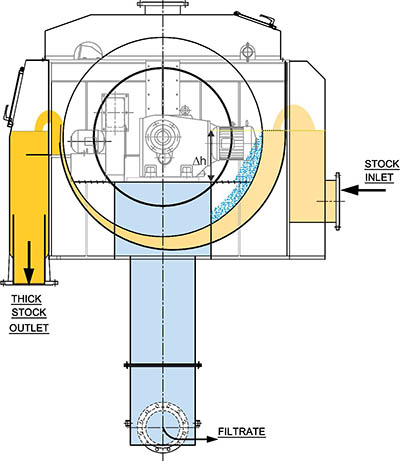

Working Principles

Parason Folded Thickner in compression to normal Thickeners provides a considerable larger filtration area. This can translate into smaller space requirement or higher capacity for specific floor space. The wire clothing is divided into sectors so that each section can be replaced without removing the drum/cylinder .

Parason Folded Thickner in compression to normal Thickeners provides a considerable larger filtration area. This can translate into smaller space requirement or higher capacity for specific floor space. The wire clothing is divided into sectors so that each section can be replaced without removing the drum/cylinder .

The stock suspension fed into cylinder through an inlet which evenly distributes the stock across the width of the thickener. The water passes through the wire mesh and the fiber mat is formed on the surface of the cylinder. Between the stock level in the vat and the surface of the drain water inside the cylinder, a hydrostatic pressure difference (∆h) is produced, which provides continuous filtration. The surface of the wire cloth cleaned by shower.

As Thickener for:

As Thickener for:

– Recycle Fiber, Chemical and Mechanical pulp

– Eflluent Sludge

– Broke

– Chemical Industry

As Washer for:

– Deinked Pulp

– Removal of Fillers and Fines from Recycled Fiber Pulp

The following relationships are applicable

Low freeness – High throughput capacity

High freeness – Low throughput capacity

High Feed Consistency – High throughput capacity

Low Feed Consistency – Low throughput capacity

History- Making of Parason

Parason started by Dr. C P Desarda (Doctorate in Metallurgy) from BRNO University, Prague, Czech Republic in 1970. Dr. Desarda innovated manufacturing of Refiner.

Parason - Over View

PARASON has installed more than 4000 nos of Disk Refiners, 500 nos Conical Refiners and approx 1600 nos of screens in India and overseas of different size and capacities.

Parason at Aurangabad

Aurangabad city is well connected by all means of transport from all corners across the globe. Aurangabad has good air connectivity too from Delhi, Mumbai and other Metro cities of India.