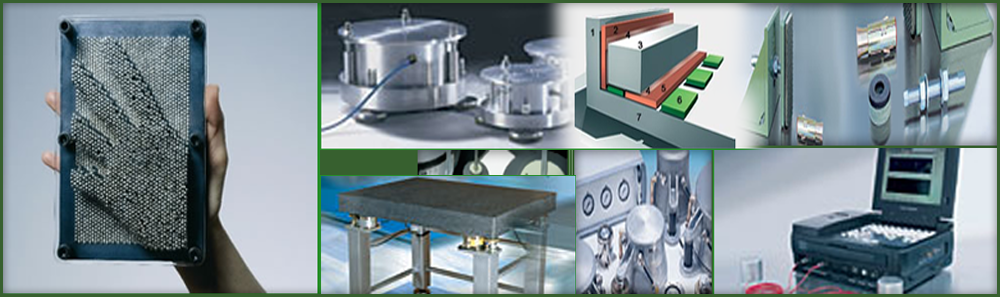

Tapping Attachments TSFL ( Non Reversible)

Our Tapping Attachments TSFL ( Non Reversible) come with the following fetures which ensure the Quality of your tapping & prevent tap breakage.

T : Twin Chucking : Our attachments hold your attachment both, on diameter as well as on the square thus giving it positive drive.

S : Safety Clutch : The built in safety mechanism, operates as soon as the set torque limit is crossed & save the tap from breakage.

F : Float Radial Parallel: Small misalignments are taken care of by this float.

L : Length Compensation: Built in Length compensation takes care of small push or pull to the spindle or feed difference.

Tapping operations have traditionally been very tricky to execute due to frequent tap breakage & inconsistently quality of tapping.

Research has shown that the important reasons causing tab breakage are as follows:

1. Tap Related Problems:

a. Wearing of Tap cannot be easily quantified ( Use of Worn out taps)

b. Use of tap with improper tap geometry for a particular application.

c. Use of non standard/inferior quality Taps.

2. Chip Clogging

a. Tapping dies not follow the pre tap hole ( misalignment )

b. Mismatch of machine feed & tap feed may cause the tap to break in tension/compression.

c. Use of improper cutting fluid.

d. No safety mechanism to limit torque below torque breakage value of tap.