Case Studies

Application of Bilz Round Mounts ( BNSH120-32 ) for Rubber Mixing Mill at Prasad Polymers Pvt. Ltd.

Tag it:

Customer: M/s. Prasad Polymers Pvt. Ltd. Pune,India (Manufacturer of Rubber erasers)

Problem faced: Customer is having a rubber mixing mill which is having fabricated base. It has total 8 supports. The mixing mill was placed on local made anti vibration mounts on the first floor of two storey industrial estate. As soon the mill is started a lot of vibrations are created and transferred to the slab. The slab is to literally shake. All the neighbors in the industrial area used to complain about the vibration to their precision machines such as turning & machining centers. Due to these vibrations precision machines could not be run. Hence the rubber mill was shifted to the rented gala on the ground floor. Customer couldn’t use his own premises & had to pay rent of Rs.15000/-per month as rent.

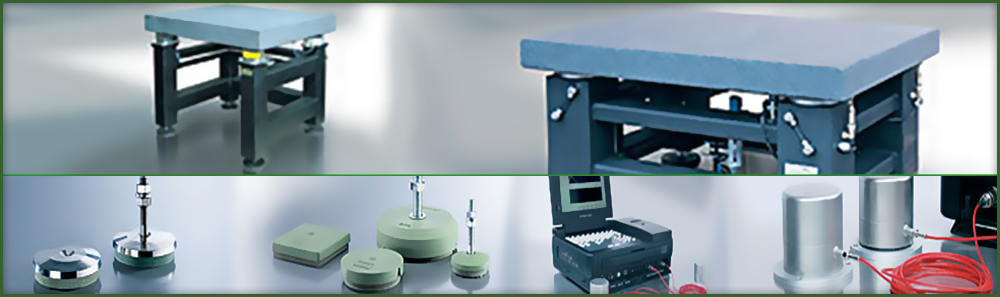

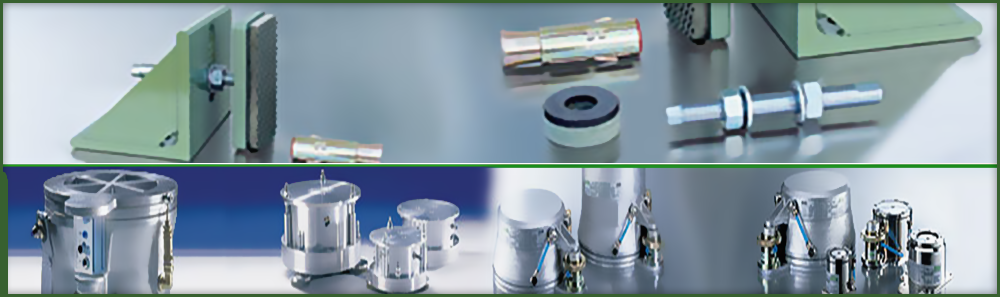

Solution: BILZ has specific rubber plate B30 & B32 for upper floor application. For this rubber mixing mill application we suggested BNSH120-32 mount at 8 mounting points.

As the mill was started absolutely NO vibrations were transferred to the slab.

By spending only about Rs.10000/- thercustomer has saved about Rs. 1,20,000/- per year of rent apart from noise free environment for his staff & his neighbors.

Tag it:

Passive Vibration Insulation Plates application for TRIMOS Metroscope at M/s.John Deere Pvt.Ltd.

Tag it:

Customer: M/s.John Deere Pvt.Ltd.

Problem faced : Flickering of last digit of the display of TRIMOS Metro scope used for calibration of gauges. The last digit represents 0.01 micron.

Description: The metroscope was placed in the metrology. The last digit of the display was flickering when some vehicle or fork lift passes by. The problem was referred to us after lot of work on the digital display by TRIMOS engineers.

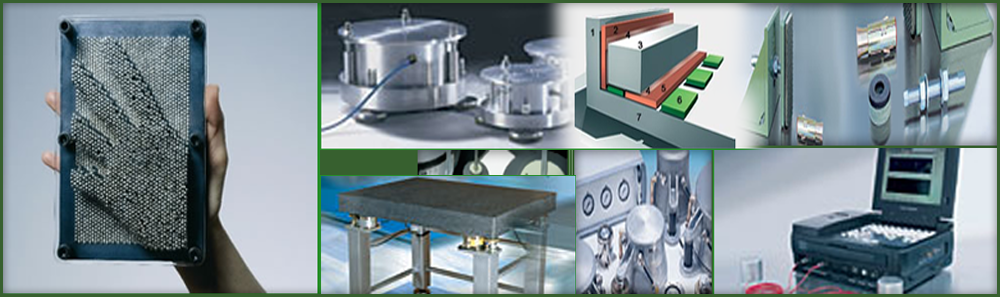

Solution Provided: Four Nos. B30W-1 (Passive vibration insulation plates) were placed in between surface plate & the stand. The problem of flickering of digit was immediately stopped. After successful usage of B30W-1 plates all the surface plates were provided with B30W-1 plates.

Bilz BiAir Application for Surface Finish Tester for Cummins India Ltd.

Tag it:

Customer: Cummins India Limited

Problem faced : No consistency in reading was observed while measuring of Surface finish value on the cam shafts which are to be exported to their parent company.

Solution: The problem was studied in detail. The application is of sub micron level measurement and the site of measurement is very near to the cam shaft rumbling machines. Customer had already tried with some local make anti vibration pads for the rumbling machines but it has not shown much effect on the vibrations.

After studying the site & the application following suggestions are given : To provide a wing type fabricated structure to mount the surface plate. This fabricated structure with surface plate is mounted on 4 Nos BILZ Bi-Air 0.5 ED membrane air spring mounts. These four mounts are interlinked with mechanical pneumatic controller. With this controller the level of the system can be maintained within 0.01 mm/meter.

Customer has measured the amplitude of vibrations before putting the BILZ system at different ambient conditions. The same exercise was repeated after putting the BILZ system.

The problem of vibration was reduced by almost 95-98%

Bilz BiAir Air Spring used for Mitutoyo CMM for M/s.Anurang Engineering Ltd (Endurance Systems)

Tag it:

Customer: M/s.Anurang Engineering Ltd, Kanhe,Tal Maval Dist.Pune ( Now Endurance Systems Ltd. )

Problem Faced: Customer is having Mitutoyo CMM which was placed in between two Makino machining centers. Whenever heavy milling cut was taken on the milling machine customer couldn’t use the CMM. They have made it a practice to use CMM in certain period of time when there will be know heavy cuts on the machine.

Solution: For this problem it was suggested to use BILZ Biair 2 ED 2 Nos & Bi air 2.5 ED 1 No. at the leveling points of the CMM along with mechanical level controller. By putting this system both the machining centers & CMM can be used simultaneously. After successful commissioning of this system customer bought three more Bi-air system for their Accurate CMM and suggested their sister concern M/s. Endurance Systems Ltd to buy one for their new Accurate CMM.