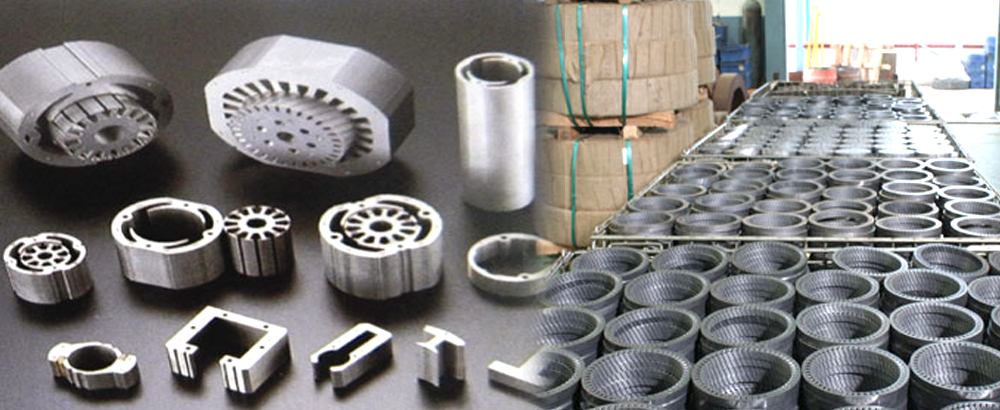

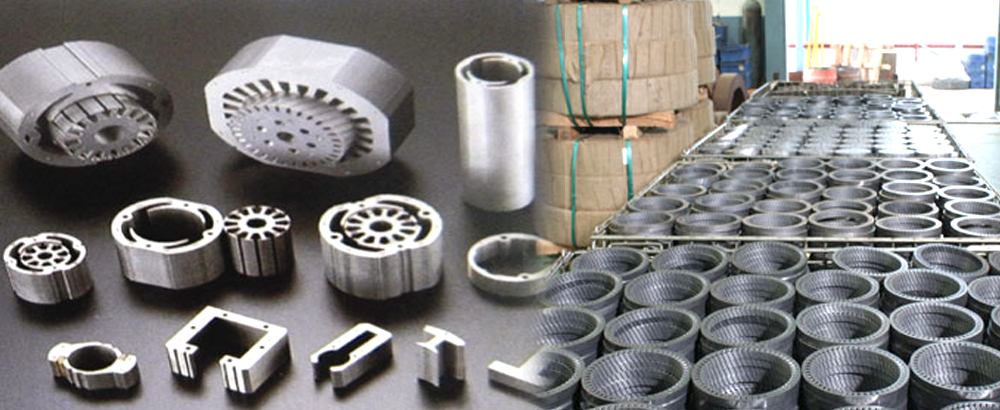

Our clients can avail from us an array of electrical stampings at the most affordable price. We have successfully catered to auto electrical stampings related needs of the customers for long time. Electrical stampings offered by us are extensively demanded in various industrial sectors where they have wide application area like automobile, motors, electrical appliances hardware, electronic hardware, frame structures, heaters, motors, pumps and valves. We also offer customization of electrical stampings as per clients requirements, making us stand among the foremost precision electrical stampings manufacturers.

Our clients can avail from us an array of electrical stampings at the most affordable price. We have successfully catered to auto electrical stampings related needs of the customers for long time. Electrical stampings offered by us are extensively demanded in various industrial sectors where they have wide application area like automobile, motors, electrical appliances hardware, electronic hardware, frame structures, heaters, motors, pumps and valves. We also offer customization of electrical stampings as per clients requirements, making us stand among the foremost precision electrical stampings manufacturers.

We offer this range which is dimensionally accurate and offered at market leading prices. To meet the specific demands of our clients and manufacture the products in accordance to the international standards, we manufacture our range with the finest quality raw material. Our range is manufactured with an in-house facility and prepared with high-speed power presses. Some of the salient features of our range are:

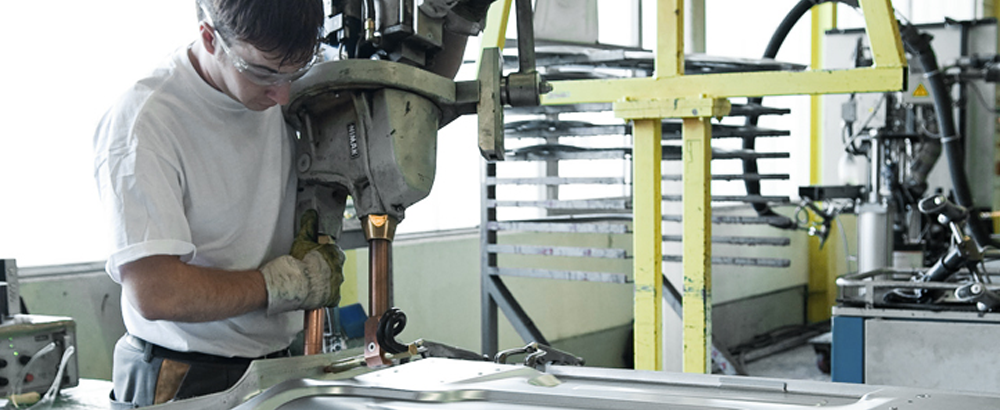

We offer a precision engineered range of sheet metal components, that are fabricated using the best quality raw material. These sheet metal components find applications in automobile, engineering and various other industries. Our range of components are known for their accurate dimensions, robust construction and better durability. Also available in customized specifications, these are strictly in compliance with the set industrial standards.

We offer a precision engineered range of sheet metal components, that are fabricated using the best quality raw material. These sheet metal components find applications in automobile, engineering and various other industries. Our range of components are known for their accurate dimensions, robust construction and better durability. Also available in customized specifications, these are strictly in compliance with the set industrial standards.

We are reckoned as one of the leading manufacturers, exporters and suppliers of wide range of Pressed Components. Our range is made from unique quality raw materials in compliance with the set quality standards. These are dimensionally accurate, well-polished and durable. Our collection finds applications in various industries due to its quality features.

We are reckoned as one of the leading manufacturers, exporters and suppliers of wide range of Pressed Components. Our range is made from unique quality raw materials in compliance with the set quality standards. These are dimensionally accurate, well-polished and durable. Our collection finds applications in various industries due to its quality features.

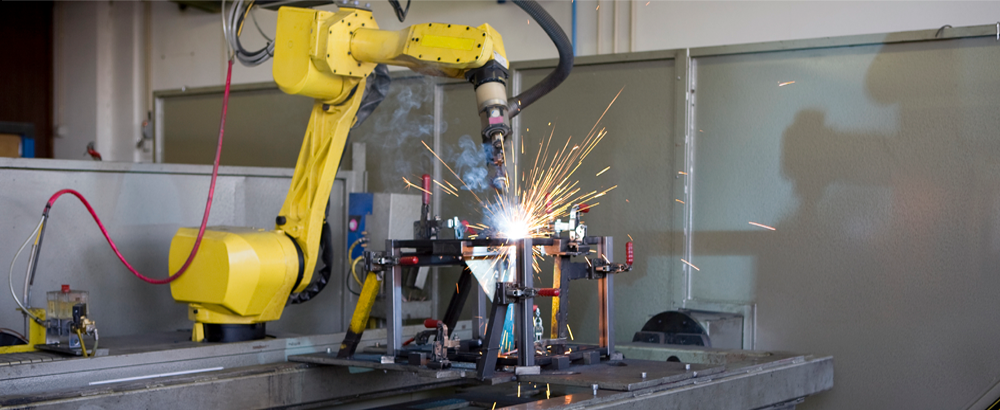

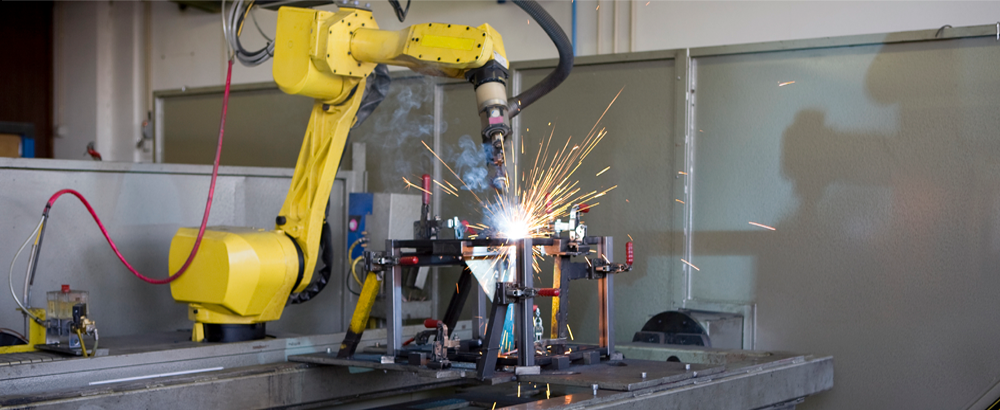

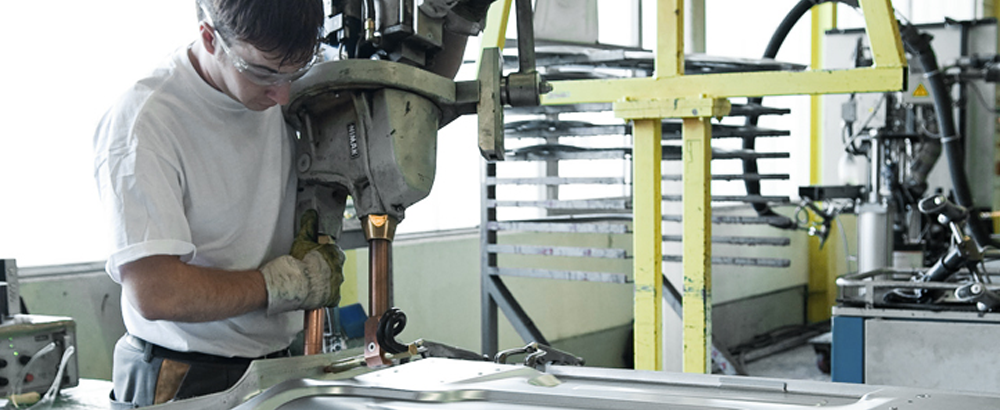

Armature assembly for Traction motor is an electric motor that provides the primary rotational torque of a machine, generally for conversion into linear motion (traction).

Armature assembly for Traction motor are used in electrically powered rail vehicles such as electric multiple units and electric locomotives, other electric vehicles such as electric milk floats, elevators and conveyors as well as vehicles with electrical transmission systems such as diesel-electric, electric hybrid vehicles and battery electric vehicles.

Armature assembly for Traction motor consists of one power source (80% duty cycle, 2 wire feeder units & 2 stationary welding rotators. The welding rotator is rotated through dc motor drive with thyristor control circuit for precise speed. The gas chosen is 95% argon and 5% oxygen.)The weld bead is bright due to oxygen in the gas. As the component is a critical part of tractor gear assembly, the component is tested at high speeds for a predetermined time and checked for weld quality before and after the test runs.

Armature assembly for Traction motor is an electric motor that provides the primary rotational torque of a machine, generally for conversion into linear motion (traction).

Armature assembly for Traction motor are used in electrically powered rail vehicles such as electric multiple units and electric locomotives, other electric vehicles such as electric milk floats, elevators and conveyors as well as vehicles with electrical transmission systems such as diesel-electric, electric hybrid vehicles and battery electric vehicles.

Armature assembly for Traction motor consists of one power source (80% duty cycle, 2 wire feeder units & 2 stationary welding rotators. The welding rotator is rotated through dc motor drive with thyristor control circuit for precise speed. The gas chosen is 95% argon and 5% oxygen.)The weld bead is bright due to oxygen in the gas. As the component is a critical part of tractor gear assembly, the component is tested at high speeds for a predetermined time and checked for weld quality before and after the test runs.

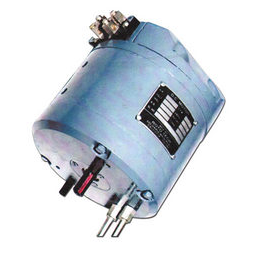

Our range of D.C. Motors is main pole and interpole which is made of laminated sheet steels. Rotors are built up of low silicon steel laminations. The insulation class for standard D.C. motors is `B¿. `F¿ & `H¿ class motors which are available as per the specific requirements. Entire range is available in horizontal foot mounting as well as vertical flange mountings type. Standard Motor is shunt wound and is also available in series and compound wound motors. AC Generators (Alternators) is vital part of the motor. D.C. geared motors are available in worm as well as helical type gear box, foot and flange mounted. Other specifications of the D.C. motors are listed below:

Our range of D.C. Motors is main pole and interpole which is made of laminated sheet steels. Rotors are built up of low silicon steel laminations. The insulation class for standard D.C. motors is `B¿. `F¿ & `H¿ class motors which are available as per the specific requirements. Entire range is available in horizontal foot mounting as well as vertical flange mountings type. Standard Motor is shunt wound and is also available in series and compound wound motors. AC Generators (Alternators) is vital part of the motor. D.C. geared motors are available in worm as well as helical type gear box, foot and flange mounted. Other specifications of the D.C. motors are listed below: