PEMCO PROCESS EQUIPMENTS (I) PVT. LTD. was established in 1977 with the aim of catering to the requirements of CHEMICAL PROCESS INDUSTRIES like polyester, pharmaceutical, distillery units. We area working in manufacturing equipments for Polyester Plant Machinery, Distillery/ Winery Plant & Botteling Machinery, Pressure Vessels, Heat Exchangers,Various Conveyors,Various Dryers,Storage Silos, Liquor Tanks & Vats.Various Mixers,Reactors.

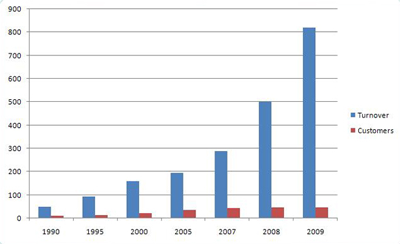

In the last 30 years the company has grown in turnover as well as the product portfolio. The company was started by experienced technocrats with experience in the areas of design & manufacture. We undertake turnkey projects for distillery & bottling units, filter cleaning for polyester units, copper powder manufacturing for bimetal bearing units.

The company is located in AURANGABAD and we have a full-fledged manufacturing Facility, skilled manpower, complete design setup and communication Infrastructure.

Promoter - Mr. Sanjiv Pathak started Pemco Process Equipments (I) Pvt. Ltd. In the year 1977. He has around 40 years of experience in the area of process equipment design & manufacturing. He is well conversant with the relevant codes for design & manufacture, like ASME, TEMA, API, etc.

Quality system – Pemco has in place a stringent quality system, to ensure the product quality. Pemco has ISO 9001-2000 quality certificate since 2004. Welding being the critical process in manufacture of fabricated process equipment, PEMCO has state of the art welding techniques with standardized procedures as per various welding standards.

Drawing and designing – PEMCO has qualified team for drawing and designing. Since most of our projects require approval of drawings from reputed consultants, basic awareness of standard drawing and designing practices is a necessity for us. PEMCO has, over the years, built up a substantial library of standards, standard components, standard procedures and other relevant literature.

PEMCO has a very strong manufacturing infrastructure with latest technologies in manufacturing.

• Fabrication – Shearing, Bending, Press Break, Plazma cutting, etc are the main machinery along with necessary hand tools and skilled manpower.

• Welding – TIG, MIG, Arc welding processes backed up with approved welders. With in-house/ out-sourced facilities for NDT testing like DP, UT, Radiography, etc.

• Polishing – Most polishing is done manually by highly skilled operators to give consistent finish. We are in the process of upgrading the polishing process by adding new mechanised equipment specifically aiming at tank polishing, pipe polishing, electro polishing.

• Inspection & testing – With rigorous in-process inspection and testing facilities for hydraulic, pneumatic testing, validation trials of equipment for proper performance, backed by calibrated measuring devices, we ensure strict quality adherence of final products.

• Raw Materials – PEMCO quality guidelines require 100% inspection of all incoming raw material along with proper identification procedures to ensure use of proper material in the process of manufacturing. All material is properly stored to preserve the qualities and avoid any contamination.

• Logistics – PEMCO has well laid out procedures for proper movement of materials both incoming and outgoing to ensure proper and timely receipts and deliveries.

• NORTH INDIA – Gurgaon, Chandigarh, Indore.

• WESTERN INDIA – Mumbai, Silvassa, Baroda, Goa.

• SOUTH INDIA – Bangalore, Hyderabad, Mysore.

• NORTH EAST – Kolkata, Guwahati, Jamshedpur, Patna.