About Us

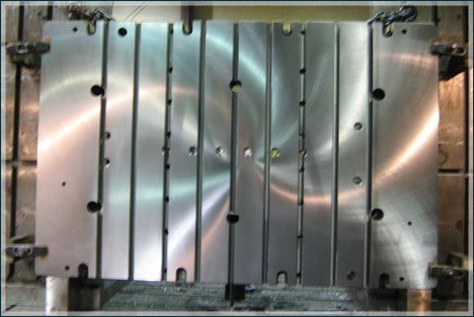

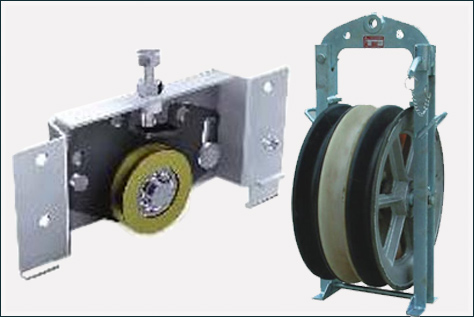

Established in the year 1998, at Pune, Maharashtra(India), we, “Prashant Engineering,” are counted amongst the prominent manufacturers and suppliers of Light, Medium & Heavy Tool Room and Machined Components Job Works. Started as a small job-working unit, we have further initiated as a manufacturer of sheet metal pressed components. Thus in April 2001, with the help of our qualified and experienced staff and operators, we have emerged as one of the renowned names engaged in offering excellent Repairing work & Fabrication work.

Our foremost objective is to serve our clients with excellent Light, Medium & Heavy Tool Room and Machined Components Job Works, thereby attaining maximum client satisfaction. To achieve this, we are installed with superior machining facilities that are being handled by our team of technical experts. Our team of professionals further keeps a tab on client's exact requirements and accordingly helps in meeting the same within the stipulated time period. Our quality approach has enabled us to acquire ISO 9001:2000 & GLC Quality Registrar certification and cater to some our valuable clients like JBM MA Magnetto Pvt. Ltd, Milton Plastics Ltd, ATS Conveyors India Pvt. Ltd and Kalyani forge Ltd.

We are operating in the field under the able guidance of our directors, Mr. B. R. Satpute and P. D. Gaikwad. With their 20 years of experience and knowledge, we have been able to offer efficient Light, Medium & Heavy Tool Room and Machined Components Job Works. They have done mechanical engineering and guide us in every sphere of business. Their sharp acumen and expertise allows our professionals to attain maximum client's satisfaction.

“'Prashant Engineering,' is mainly engaged in the manufacturing of various Light Medium & Heavy Machined Parts & Fabricated Parts. Motto of 'Prashant Engineering,' is to strive towards excellence in quality, which is achieved through development and implementation of Quality Management System maintained in line with ISO 9001:2008, with focus on meeting Customer requirements and expectations, enhancing customer satisfaction.

Quality Management System is defined, implemented in order to have proper system, transparency and clarity in working so as to achieve consistency in quality and continuous improvement in Quality performance.”

Business Philosophy

“As the Director is a technically qualified professional, the general orientation of the company is towards technical excellence. The work culture has also been developed accordingly. In addition, the company has also endeavored to meet and achieve the quality standards set by the customers also.”

Our Services

We are one of the renowned names in the field of providing valuable and excellent Light, Medium & Heavy Tool Room and Machined Components Job Works. For our job works, we make use of quality basic material like stainless steel, mild steel and alloy steel, which we procure from reliable vendors. Our job works are highly appreciated by our clients as these are reliable, cost-effective and are well executed on time. Apart from this, we also facilitate our clients by providing them with right solutions in the field of Repairing & Fabrication Work. Our prompt services have helped us in achieving the trust & confidence of our clients, thereby retaining our credibility amongst our valuable clients.

Our Team

We are empowered by a team of skilled and qualified professionals, which have helped us to ensure excellent Light, Medium & Heavy Tool Room and Machined Components Job Works. Our professionals also hold expertise and in-depth process knowledge in their respective domain of work. In our team, we have following professionals:

- Engineers

- Technicians

- Quality controllers

- Skilled and semi skilled workers

Backed by a rich industry experience, our team is also proficient in offering job works as per the specifications laid down by our clients. In addition, our quality controllers test the entire job work at each and every level so as to ensure the international quality standards in our works. It is through the unwavering efforts of our professionals, we have been able to serve our clients with efficient job works.

Being client centric, our primary objective is to serve our clients with quality range of products and valuable services. The Light, Medium & Heavy Tool Room and Machined Components Job Works we offer, extensively meet the demands of various Electronic, Engineering, Automobile and Allied Industries. Apart from this, we also provide the customization of valuable services as per their specifications.

Some of our valuable clients are as follows:

- M/s. TATA Motors Ltd., Pimpri, Pune.

- M/s. Thermal Ltd., Pune

- M/s. Mahindra (Masco Stampings Ltd. Pune & Nashik)

- M/s. Wheels India Ltd., Ranjangaon, Pune,

- M/s. GKW Limited, Pune

- M/s. ATS Conveyors India Pvt. Ltd., Bhosari Pune ( Germany & France)

- M/s. Kiron Hydraulics Needs Pvt. Ltd, Mumbai (USA)

- M/s. JBM MA Magnetto Pvt. Ltd., Chakan, Pune (Indo-Italy)

- M/s. Thai Sumccl Ncel Auto Pvt. Ltd., Chakan, Pune (Indo- Thailand)

- M/s. Kalyani forge Ltd., Sansanadi, Pune

- M/s. Milton Plastics Ltd., Sansanadi, Pune

- M/s. Reliable Auto tech Pvt. Ltd. Chakan , Pune

- M/s. Ordanace Factory, Dehu Road, Pune

- M/s. Ammunition Factory, Khadaki, Pune

Why Us?

Being in the industry for 12 years, we have achieved a remarkable position for ourselves in the industry. Owing to the following key factors, we have been able gain the trust and confidence of our valuable clients:

- Quality work

- Client centered approach

- Efficient professionals

- Reliable process approach

- Cost-effective

- Timely execution