Manufacturing Facilities

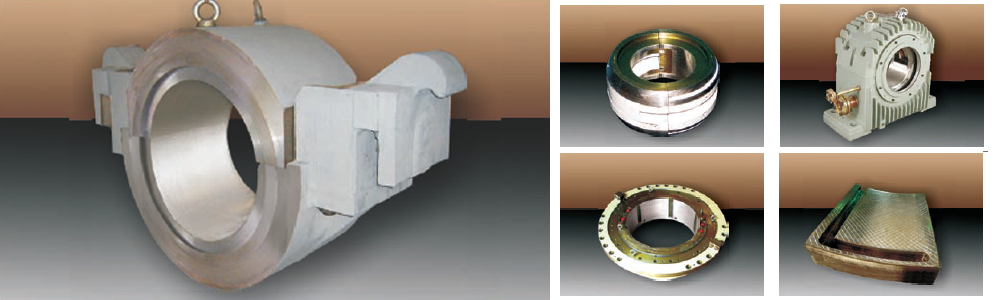

Currently Precimax Group offers products and services from three locations in India. All these facilities are fully equipped with modern CNC machines, babbit casting machines, vertical and horizontal centrifugal lining machines, entire range of pre-lining, post-lining and heat treatment facilities.

Two new facilities are being set up, one in Baroda and another in an international locale.

Special manufacturing processes such as dehydrogenation for fabricated bearings, vibro static lining etc., are available.

Well developed management systems are practiced in procurement, manufacturing, QA procedures and customers support.

The synergy of the three units enables the group to effectively undertake manufacturing programmes including standard bearings, customer defined bearings as well as re-babbitting, re-engineering and retrofitting services.

Total Quality Management

The quality systems implemented and followed by the group ensures that every product undergoes strict quality checks at every stage of manufacturing, right from raw material to finished components. Total customer support from pre-sales to after-sales service is an integral part to Precimax quality management. The quality systems are certified as per ISO 2000.

All products and components are subjected to chemical, physical and non-destructive tests. Some of these are UT tests foe bond adhesion, DP tests for solidity of lining and MPI tests foe shell soundness.

Any special tests such as hydro tests, residual stress tests and radiographic tests specific to a product can be carried out with external assistance . Facility for third party inspection is available.

Precimax bearings are also exported with CE certification. Bearings can be manufactured for international customers as per country specific certification.