Nature Of Inspection Carried Out On Raw Material:

We check the dimensions on sample basis after receipt of material and record the remark (aoc./rej.etc.) on Incoming / Raw Material receipt details. We accept the Material after receiving Material Test Certificate at our end with every lot we arrange.

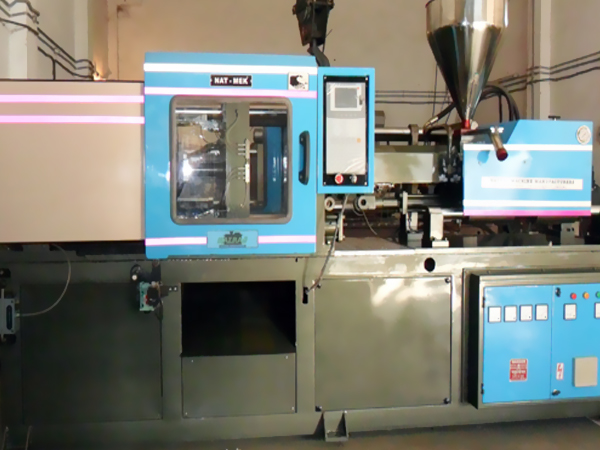

For the purpose of manufacturing best quality industrial products, we have set up a huge infrastructure. Our infrastructure under the mentorship of mentor, Mr. Rajendra Abhang, has divided into several units. Manufacturing, in-house quality testing unit and sales & marketing units are essential components of our infrastructure. This division ensures that all the on-going processes are carried out in streamlined manner. To handle different units of infrastructure, we have appointed a team of technicians.