Products and Services

Expertise in 6 major automotive segments

- Suspension system assemblies:

lower wishbone, top wishbone, assemblies for front and rear axles, leaf spring shackles. - Functional Assemblies:

Steering Columns, Spare Wheel Carriers, Gear Shift Levers, Accelerator, Brake and Clutch Pedals. - Special Vehicle Customization:

Bullet Proofing, vehicle customization for uses such as – ambulances, medical vans, mobile labs. - Floor Assemblies for Passenger Vehicles and Trucks

- Frame and Chassis assemblies

Projects in thePipeline

- Developing and manufacturing parts for TATA Nano (small car)

- Setting up Manufacturing Facility in Jamshepur

- Setting up Chassis Frame Assembly for Safari (SUV)

- Setting up Press Shop in Jamshedpur

Awards & Certificates

- Award for Excellence in overall performance in Mechanical Category from Mr.Ravikant (MD TML) – year 2008

- Award for delivery performance in all categories – year 2009

- Award for long relations with TATA Motors (30 years - year 2009

Products

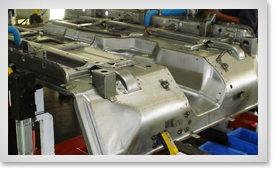

We are traditionally a sheet metal production house with expertise in all types of sheet metal parts production capabilities. Over the years we have gained significant expertise and knowledge of manufacturing assemblies such as:

We are traditionally a sheet metal production house with expertise in all types of sheet metal parts production capabilities. Over the years we have gained significant expertise and knowledge of manufacturing assemblies such as:

- ASSY. LOWER WISHBONE

- ASSY. TOP WISHBONE

- ASSY. CONTROL MTG. BRACKET WITH LEVER

- and other such assemblies.

Projects

We have executed various projects for our customers which involve armed forces and government projects which are sensitive and of confidential nature. Some of these projects involved building of concept vehicles with customer drawings.

We have executed various projects for our customers which involve armed forces and government projects which are sensitive and of confidential nature. Some of these projects involved building of concept vehicles with customer drawings.

We have in-house capabilities of complete vehicle customization.

We have successfully completed projects such as, TATA SAFARI ARMOURED, TATA SUMO ARMOURED, TATA LIGHT SPECIALIST VEHICLE, TATA SUMO ARMY AMBULANCE, TATA SUMO JAMMER, TATA WINGER AMBULANCE and other such projects.

Solutions

We have developed cost-effective solutions for our customer by offering vertically integrated assemblies such as, ASSY. SUBSTRUCTURE WITH FLOOR, ASSY.FACELESS COWL SUBSTRUCTURE.

We have developed cost-effective solutions for our customer by offering vertically integrated assemblies such as, ASSY. SUBSTRUCTURE WITH FLOOR, ASSY.FACELESS COWL SUBSTRUCTURE.

These assemblies serve as the starting of a BIW line. These have helped in reducing the manufacturing cost of our customer and increased their output.