About Us

Shree Industries is privately- held company , specializes in manufacturing the high pressure aluminum die casting, zinc die casting, gravity die casting components as per the customer requirements. The company can supply the machined and finished assemblies .The company has been in business for twenty years.

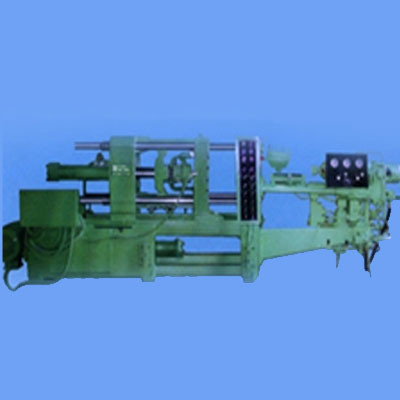

Shree Industries is into manufacturing of PDC machine from 60 Ton to 180 Ton capacity with Three Phase Injection systems. The machines will have dedicated trouble free PLC.

The company has full fledged computer aided design centre for designing the dies and moulds for any type of die cast components. The dies are made with the help all modern CNC machines i.e. Vertical machining centre, EDM machine. The die parts such as core and cavity inserts are made from superior quality tool steel and properly Vacuum Hardened to enhance its tool life. The Tool Room is managed by qualified Tool Room Engineers from GTTC and NTTF Technical Institutions.

Shree Industries has the capacity to add value to the pressure die casting components. This is achieved by means of Pressure test ,Surface finishing, Powder coating and Assembly of other parts.

Shree Industries is committed to achieve excellence in customer satisfaction by providing them superior quality die cast tools and components at very reasonable prices. We also strive to meet the customer specified delivery period and prompt service support. This shall be met through continuous improvement in manpower, technical up gradation and by reviewing our resources time to time.

We also recommend tool design and quality control checks and overall improvement of Quality Management system in the organization.

ISO 9001:2008: Shree Industries has obtained ISO 9001:2008 on 7th January 2010 for the period of 3 years. ISO certification is approved and issued by UKAS & Moody International Accreditation body.

Quality Control

- We are a quality conscious organization and leave no stone unturned to manufacture best quality die cast tools, components and assemblies. The quality policy we have drawn, governs us to follow all steps to maintain consistency in our products quality. These steps include the following:

- Designing of products as per customer specifications.

- Sourcing best available raw material with analyzing test report.

- Continuous upgradation of skill of employees and technology.

- Following stringent quality measures throughout the manufacturing process.

- Quality testing of in process and finished products.

- Ensuring scheduled delivery.

- Collecting feedback from the customer about the products & services.

- Minimizing the tool trials.

- Infrastructure:

To make the best use of our immovable assets we have trained labor, qualified engineers & a professional supervising team. We use all the great modeling software which are used for designing of dies and products. We also have a small but effective R&D team that not only keeps us up-to-date with the trends of accelerating world market but also empower us with the innovative technologies.

- Few of the machines we have for manufacturing and assembly in our Tool Room are as below:

- CNC milling machine. ( VMC )

- M1TR milling ( Taiwan )

- EDM Spark Erosion Machine.

- Milling Machines BFW make.

- Surface Grinding Machine

- Lathe Machines

- Radial Drilling Machines

- Horizontal Moulding Machines (Die Casting)

The machining part our Dies is done on CNC Milling, EDM, Wire cut, CNC Lathe. We make fully hardened & ground dies as per customer specifications. All our die inserts are Vacuum Hardened & Plasma Nitrated to increase the life of the tool.

- Choose us for:

- High quality products

- Customized engineered goods

- Competitive pricing

- Timely delivery

- Samples provided on request

- Ethical business practices

Few of the die casting machines we have for Assembly in our Tool Room

Horizontal Moulding Machines

(Die Cast)

Few of the machines we have for machining of dies in our Tool Room

CNC milling machine

One of the machines we have for precision grinding of core, cavities and inserts in our Tool Room

Surface Grinding Machine

Few of the EDM machines we have for in house facility in our Tool Room

EDM Spark Erosion Machine Cosmos V-80

Lathe machine we have for in house turning and polishing of mould parts in our tool room