Products

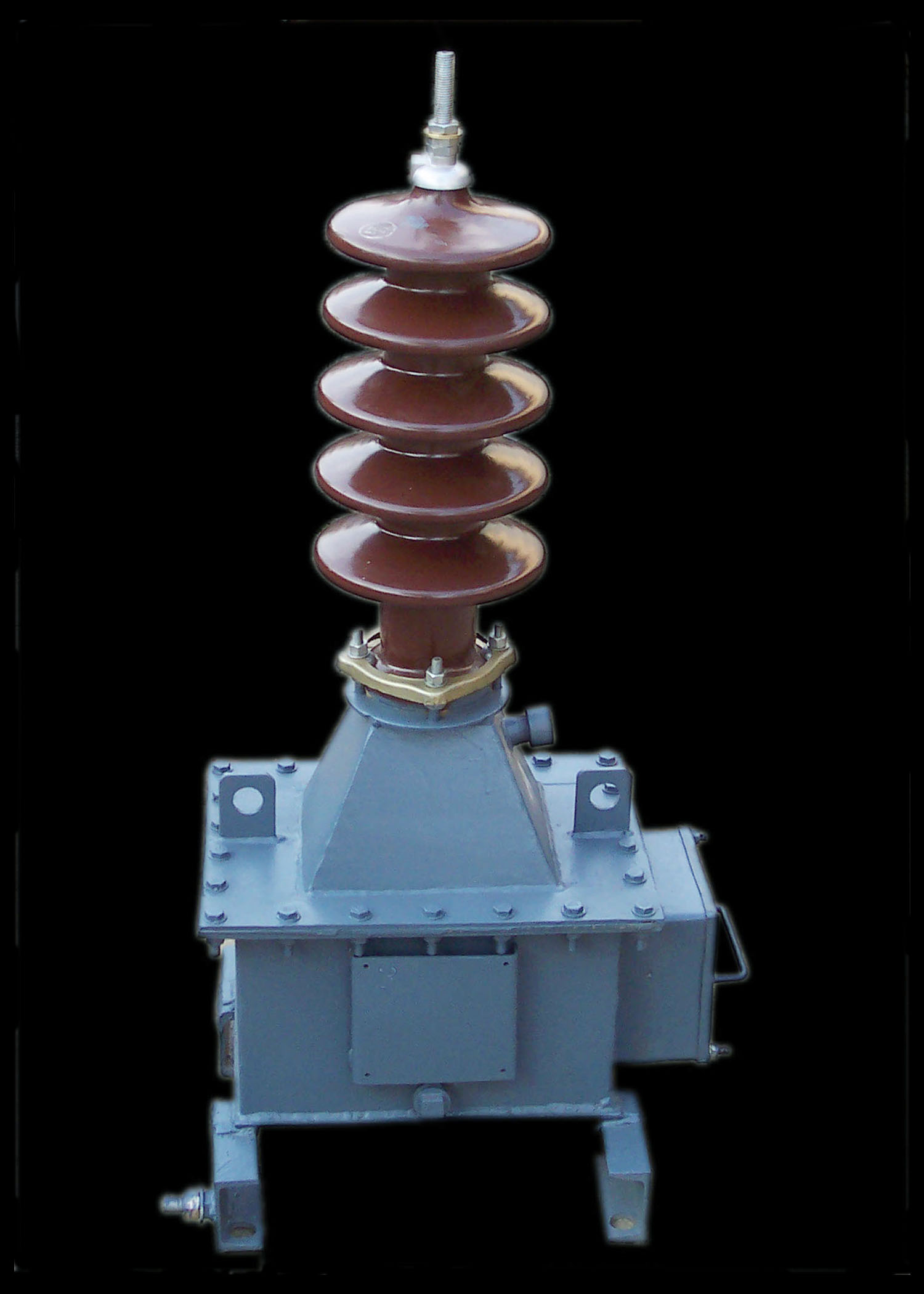

POTENTIAL TRANSFORMERS.

MANUFACTURING POTENTIAL TRANSFORMERS.

TECHNICAL INFORMATION:

TBD.

QUALITY:

All the manufacturing activities like design, lamination cutting, core formation, paper covering, winding, assembly, tanking, tank fabrication, vacuum, ovening, testing, oil filtration etc is done in house and the raw material purchased also goes through severe quality checks throughout the manufacturing process and hence contributes to the quality of the finished product. Final testing is carried out as per the specified standards.

All the manufacturing activities like design, lamination cutting, core formation, paper covering, winding, assembly, tanking, tank fabrication, vacuum, ovening, testing, oil filtration etc is done in house and the raw material purchased also goes through severe quality checks throughout the manufacturing process and hence contributes to the quality of the finished product. Final testing is carried out as per the specified standards.

Following Routine tests as per the IS norms are carried out.

- 1. Measurement Of Insulation resistance

- 2. Measurement of voltage ratio & vector Group relation.

- 3. Separate source withstand voltage test.

- 4. Induced overvoltage withstand test.

- 5. Measurement of No load losses & current.

- 6. Measurement Of Impedance Voltage & Load Loss.

- 7. Measurement of winding resistance.

- 8. Oil dielectric test.

- 9. Magnetic balance test.

Special tests as required by the customer are also carried out.

Our Quality assurance plan is focused on providing uncompromising quality to our valued customers to ensure lasting satisfaction. Our quality can be best judged by the simple fact that there are huge numbers of satisfied customers all over India who have placed repeated orders on us.

DOWNLOADS:

- MANUAL & INSTALLATION & COMISSIONING GUIDE

- TRANS-DELTA LEAFLET

- PRESENTATION OF FAILURE CASES

- PRESENTATION OF MANUFACTURING PROCESS

- PRESENTATION OF TESTING, MAINTENANCE & PROTECTION OF TRANSFORMERS

MANUFACTURING PROCESS:

To view manufacturing Process Please click here