UNIQUE CIRCLE GROUP formerly known as UNIQUE CIRCLE GASKET CO. was started in December 1995, with the main aim to manufacture Gasket & Thermocole Patterns for OEM Automotive Companies.

UNIQUE CIRCLE GROUP formerly known as UNIQUE CIRCLE GASKET CO. was started in December 1995, with the main aim to manufacture Gasket & Thermocole Patterns for OEM Automotive Companies. The company was formed by Mr. Parag Shah an ex–employee of TATA Motors & Bajaj Auto Ltd., who has had experience in Pattern Making and Checking Fixtures for the past 22 years. With a strong background of the automobile sector and dreams to lead the industry in its class, the company named 'UNIQUE CIRCLE' was Born in the year 1995. Starting with only 2 employees, the U.C. Group now boasts a team of 114 associates and 47 Engineers and is one the leading names in automobile checking / Inspection Fixtures in India today.

UNIQUE CIRCLE GROUP formerly known as UNIQUE CIRCLE GASKET CO. was started in December 1995, with the main aim to manufacture Gasket & Thermocole Patterns for OEM Automotive Companies. The company was formed by Mr. Parag Shah an ex–employee of TATA Motors & Bajaj Auto Ltd., who has had experience in Pattern Making and Checking Fixtures for the past 22 years. With a strong background of the automobile sector and dreams to lead the industry in its class, the company named 'UNIQUE CIRCLE' was Born in the year 1995. Starting with only 2 employees, the U.C. Group now boasts a team of 114 associates and 47 Engineers and is one the leading names in automobile checking / Inspection Fixtures in India today.

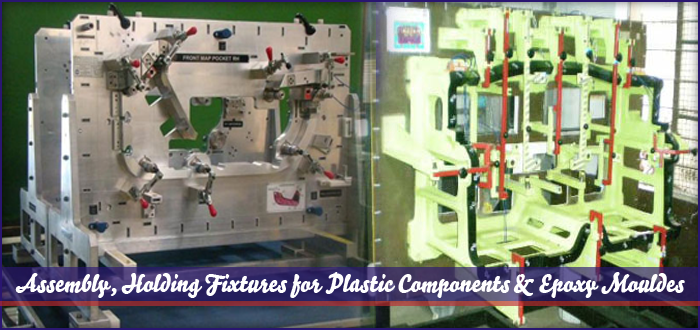

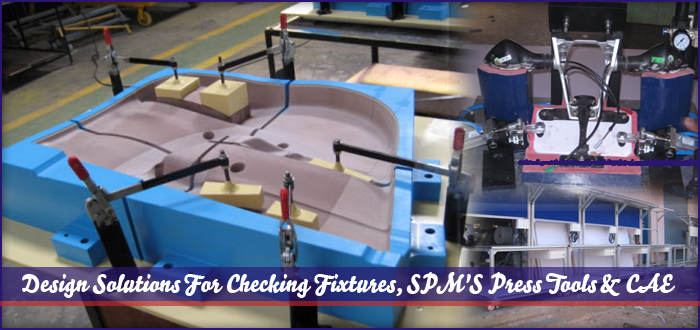

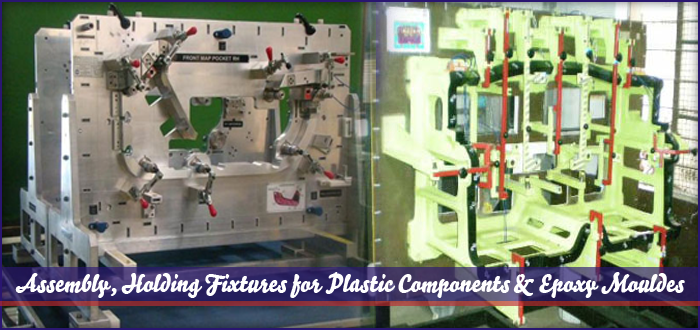

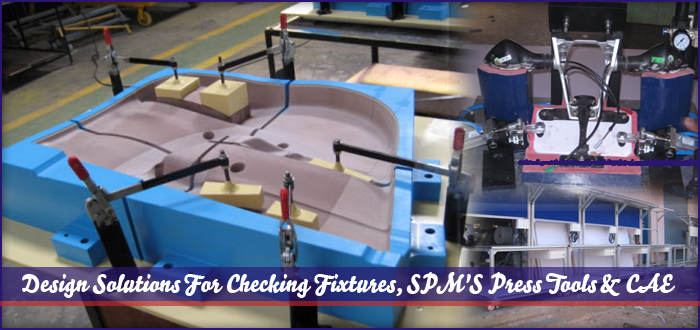

Unique Circle Group are specialists in the designing and manufacturing of automotive inspection / checking fixtures (Sheet metal Panel / Plastic Component). It also manufactures fixtures for all types of Head & Tail Lamps, Holding Fixtures, Assembly Fixtures, Cooling Fixtures, Vibration Welding Fixtures, FRP Components, Special Purpose Machinery (SPM) for Plastic Components, Ultrasonic Welding Fixtures, Robotics Fixture and Punching Tools for plastic components and is catering to a wide scope of industries in the diverse range of the automotive market sector. Established for over 15 years, Unique Circle has the technical competence and capabilities to manage large Scale complex projects and regularly manage customers' complete tooling requirement from Concept Design, CAD/CAM Modelling to Development and Production and after sales support. All projects undertaken by Unique Circle are subject to extensive planning: We pride ourselves in our professional project management techniques.

Unique Circle Group are specialists in the designing and manufacturing of automotive inspection / checking fixtures (Sheet metal Panel / Plastic Component). It also manufactures fixtures for all types of Head & Tail Lamps, Holding Fixtures, Assembly Fixtures, Cooling Fixtures, Vibration Welding Fixtures, FRP Components, Special Purpose Machinery (SPM) for Plastic Components, Ultrasonic Welding Fixtures, Robotics Fixture and Punching Tools for plastic components and is catering to a wide scope of industries in the diverse range of the automotive market sector. Established for over 15 years, Unique Circle has the technical competence and capabilities to manage large Scale complex projects and regularly manage customers' complete tooling requirement from Concept Design, CAD/CAM Modelling to Development and Production and after sales support. All projects undertaken by Unique Circle are subject to extensive planning: We pride ourselves in our professional project management techniques.

We are one of the leading manufacturers of Automotive/Inspection Fixtures and SPMs. These are manufactured with the international standards quality and requirements of various automotive & engineering industries.

Our range encompasses:

3D Machining For Patterns

Features:

Sturdy construction

Reliable

As per various quality standards

We are one of the leading manufacturers of Automotive/Inspection Fixtures and SPMs. These are manufactured with the international standards quality and requirements of various automotive & engineering industries.

Our range encompasses:

3D Machining For Patterns

Features:

Sturdy construction

Reliable

As per various quality standards

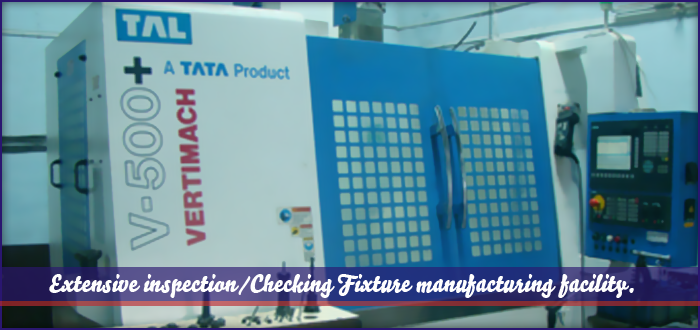

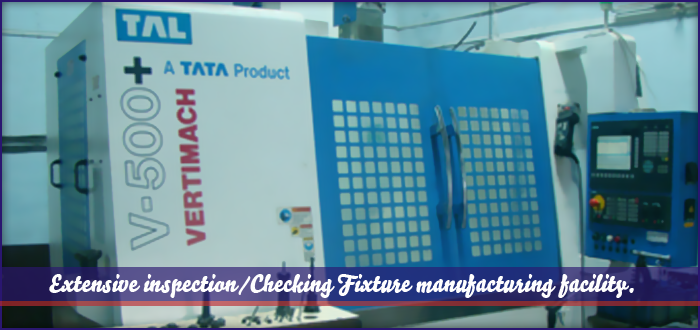

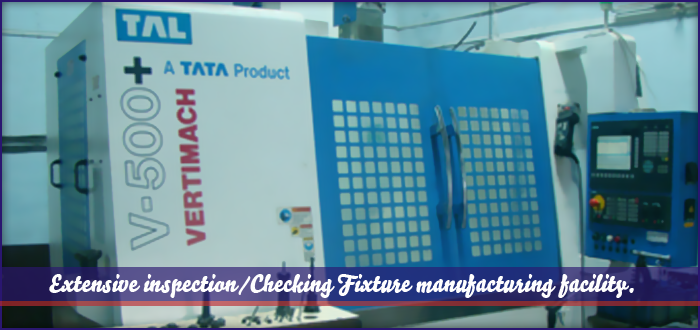

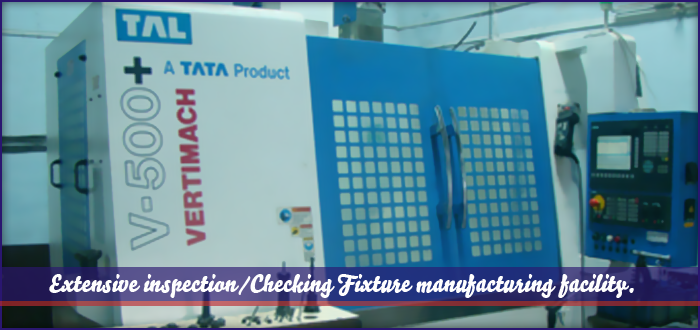

The very latest in C.N.C. machining with multiple CNC/VMC machines.

The very latest in C.N.C. machining with multiple CNC/VMC machines.

Extensive inspection/Checking Fixture manufacturing facility.

Large modern CAD Design Room including the very latest CAD/CAM softwares.

In-house CAD/CAM Component / Tool Designing.

Complete Toolroom for In-house manufacturing.

Complete fabrication section to take care of all Fabrication works.

Large Capacity C.M.M. (Cantilever & Bridge type) and multiple Portable C.M.M.’s (Faro machines) for on-site inspections as well.

Extensive SPM and Punching tools manufacturing facility.

Extensive pattern making (Thermocole or Polystyrene / Holding Fixture (P.U.) making facility.

Highly Skilled and Competent workforce having years-on experience in their respective fields.

Well equipped (Video & Audio Conferencing) Conferencing Rooms.

Easy access to the facilities through Road/Rail/Air.

Extensive E-Master Cubing and Automated Fixture manufacturing facility.

Upcoming Completely dedicated E.O.U. unit (Upcoming) catering only to Foreign OEM Automotive Majors.