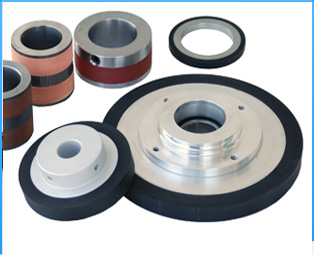

Moulded Rubber Products

Highly appreciated

Long service life

High wear and tear resistance

Durable

Durable

Easy maintenance

Long functional life

Durability

Silicon Rubber O Rings

We bring forth our clients a wide range of Moulded Rubber Products that is utilized in several industries and other applications. Our molded rubber products are manufactured using high quality raw material and contemporary technologies, in adherence to set industrial standards. In addition to this, our clients can avail these products in different specifications as per their choices and demands.

Rubber Seal

Backed by our skilled professionals and high-end technologies, we are able to offer highly efficient Rubber Seal that are widely use in automobile industry. These rubber seals are used to prevent leakage of oil from automobile and thus results in improving its performance. Furthermore, our products are available in various specifications to meet the divergent needs of our esteemed clients.

Backed by our skilled professionals and high-end technologies, we are able to offer highly efficient Rubber Seal that are widely use in automobile industry. These rubber seals are used to prevent leakage of oil from automobile and thus results in improving its performance. Furthermore, our products are available in various specifications to meet the divergent needs of our esteemed clients.

Features:

Rust free

Highly appreciated

Long service life

Rubber O Ring

We are a well known manufacturer and supplier of Rubber O Ring. These rubber O rings are highly used to satisfy various industrial requirements of power plants and automobile industries. Our offered products are highly fluid resistant, corrosion and high temperature resistant. In addition to this, these are available in various dimensions and sizes to meet the needs of the clients.

We are a well known manufacturer and supplier of Rubber O Ring. These rubber O rings are highly used to satisfy various industrial requirements of power plants and automobile industries. Our offered products are highly fluid resistant, corrosion and high temperature resistant. In addition to this, these are available in various dimensions and sizes to meet the needs of the clients.

Features:

Highly fluid resistant

High wear and tear resistance

Durable

Rubber Grommet

We are eminent manufacturer and supplier of Rubber Grommet. These rubber grommets have a high melting point and can also bear high temperature and pressure. Our offered products are light in weight and can be customized. These products are widely used in various industries and appreciated by our clients. Furthermore, products can be easily availed from us at the most reasonable market prices.

We are eminent manufacturer and supplier of Rubber Grommet. These rubber grommets have a high melting point and can also bear high temperature and pressure. Our offered products are light in weight and can be customized. These products are widely used in various industries and appreciated by our clients. Furthermore, products can be easily availed from us at the most reasonable market prices.

Features:

High mechanical strength

Durable

Easy maintenance

EPDM Rubber Strip

With our vast experience in the industry, we are able to manufacture and supply EPDM Rubber Strip. These EPDM Rubber Strips are use in several sealing applications such as ships, containers, windows and trains, our product is used in quake-reduction of several highways, architectures and bridges. In addition to this, our offered products are available at market leading prices.

With our vast experience in the industry, we are able to manufacture and supply EPDM Rubber Strip. These EPDM Rubber Strips are use in several sealing applications such as ships, containers, windows and trains, our product is used in quake-reduction of several highways, architectures and bridges. In addition to this, our offered products are available at market leading prices.

Features:

Easy to fix or removeh

Long functional life

Durability

Moulded Silicon Rubber Products

We offer a wide range of flexible Moulded Silicon Rubber, which can be manufactured as per client's requirements. These are offered at industry leading prices.

We offer a wide range of flexible Moulded Silicon Rubber, which can be manufactured as per client's requirements. These are offered at industry leading prices.

Silicon Rubber O Rings

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Their chemical structure allows Silicones to be the most benign of all rubbers in medical applications (again, the exception are some very costly Fluoroelastomers). Cytotoxity tests of Silicone parts made with simple formulations show no adverse effects.

The US military applies the longest shelf life criteria to Silicone rubber components. For example, a coolant hose made with Silicone meeting SAE J20, is given a shelf life of 20 years, whereas those made with chloroprene rubber meeting SAE J20 are given a shelf life of 8 years.

The benign nature of this rubber makes components made with Silicone ideal for electronic applications, where long life and chemical inertness are essential to good electrical integrity over the component's life. Silicone rubber parts can be made extremely conductive (resistivity of 0.0001Ω cm) or highly insulative (resistivity of 1015Ω cm).

In the automotive components market Silicone rubber has found major utilities in break line components, electrical grommets, radiator hoses, fuel line check valves (Fluorosilicone) and Oil Pan and Rocker Cover gaskets, as well as Spark Plug boots. It is estimated that in a modern car, 25% of the rubber components (excluding tires) are made of Silicone rubber.

Silicon Rubber Strips

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Their chemical structure allows Silicones to be the most benign of all rubbers in medical applications (again, the exception are some very costly Fluoroelastomers). Cytotoxity tests of Silicone parts made with simple formulations show no adverse effects.

The US military applies the longest shelf life criteria to Silicone rubber components. For example, a coolant hose made with Silicone meeting SAE J20, is given a shelf life of 20 years, whereas those made with chloroprene rubber meeting SAE J20 are given a shelf life of 8 years.

The benign nature of this rubber makes components made with Silicone ideal for electronic applications, where long life and chemical inertness are essential to good electrical integrity over the component's life. Silicone rubber parts can be made extremely conductive (resistivity of 0.0001Ω cm) or highly insulative (resistivity of 1015Ω cm).

In the automotive components market Silicone rubber has found major utilities in break line components, electrical grommets, radiator hoses, fuel line check valves (Fluorosilicone) and Oil Pan and Rocker Cover gaskets, as well as Spark Plug boots. It is estimated that in a modern car, 25% of the rubber components (excluding tires) are made of Silicone rubber.

Bonded Silicon Rubber Roller

![]() Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Their chemical structure allows Silicones to be the most benign of all rubbers in medical applications (again, the exception are some very costly Fluoroelastomers). Cytotoxity tests of Silicone parts made with simple formulations show no adverse effects.

The US military applies the longest shelf life criteria to Silicone rubber components. For example, a coolant hose made with Silicone meeting SAE J20, is given a shelf life of 20 years, whereas those made with chloroprene rubber meeting SAE J20 are given a shelf life of 8 years.

The benign nature of this rubber makes components made with Silicone ideal for electronic applications, where long life and chemical inertness are essential to good electrical integrity over the component's life. Silicone rubber parts can be made extremely conductive (resistivity of 0.0001Ω cm) or highly insulative (resistivity of 1015Ω cm).

In the automotive components market Silicone rubber has found major utilities in break line components, electrical grommets, radiator hoses, fuel line check valves (Fluorosilicone) and Oil Pan and Rocker Cover gaskets, as well as Spark Plug boots. It is estimated that in a modern car, 25% of the rubber components (excluding tires) are made of Silicone rubber.

Silicon Rubber Sleeve

![]() Silicon Rubber Sleeve is used in packaging machines and various other industries connected to the hopper.

Pure Silicon Rubber Sleeve useful for food packaging industry as it is considered as food grade.

We are manufacturers of all types of rubber components according to customer specifications.

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Silicon Rubber Sleeve is used in packaging machines and various other industries connected to the hopper.

Pure Silicon Rubber Sleeve useful for food packaging industry as it is considered as food grade.

We are manufacturers of all types of rubber components according to customer specifications.

Silicone rubber has historically been used in specialty applications in order to meet requirements other elastomers cannot. Silicones have the largest application temperature span of all rubbers (-120 F to +500 F, with one or two exceptions where highly specialized and costly Fluoropolymers can compare).

Their chemical structure allows Silicones to be the most benign of all rubbers in medical applications (again, the exception are some very costly Fluoroelastomers). Cytotoxity tests of Silicone parts made with simple formulations show no adverse effects.

The US military applies the longest shelf life criteria to Silicone rubber components. For example, a coolant hose made with Silicone meeting SAE J20, is given a shelf life of 20 years, whereas those made with chloroprene rubber meeting SAE J20 are given a shelf life of 8 years.

The benign nature of this rubber makes components made with Silicone ideal for electronic applications, where long life and chemical inertness are essential to good electrical integrity over the component's life. Silicone rubber parts can be made extremely conductive (resistivity of 0.0001Ω cm) or highly insulative (resistivity of 1015Ω cm).

In the automotive components market Silicone rubber has found major utilities in break line components, electrical grommets, radiator hoses, fuel line check valves (Fluorosilicone) and Oil Pan and Rocker Cover gaskets, as well as Spark Plug boots. It is estimated that in a modern car, 25% of the rubber components (excluding tires) are made of Silicone rubber.