Process of Manufacturing

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

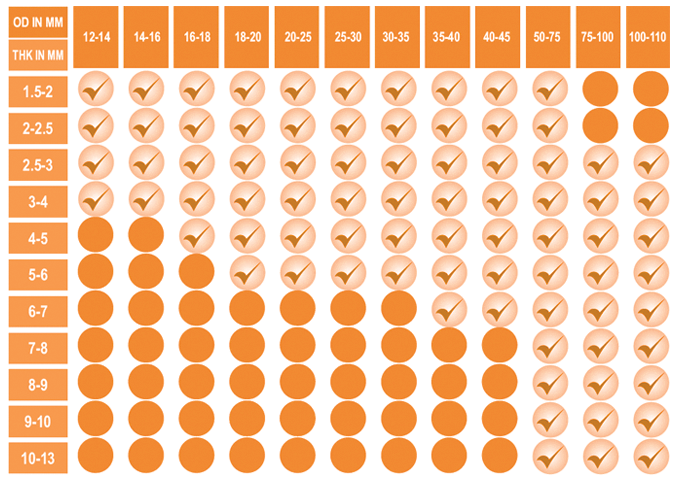

Seamless Tubes / Pipes manufacturing range

We offer materials with original MTC, IBR Certificate if required, materials will be as per customer's specifications. We can offer additional tests (hydro test, flattening, NDT, impact, chemical etc...) on these materials at our factory and the same can be witnessed by customer or its appointed Third Party Inspection.

Yashshree tubes has a focus on the market for seamless tubes

in applications like Automobile components, drill rod and mining tubes, hydraulic line pipes boilers, heat exchangers, and integral shaped tubes.

Copyright © 2016 Yashashree Tubes Pvt. Ltd. All Rights Reserved. (terms Of Use) Developed And Managed By SME Business Services Ltd.