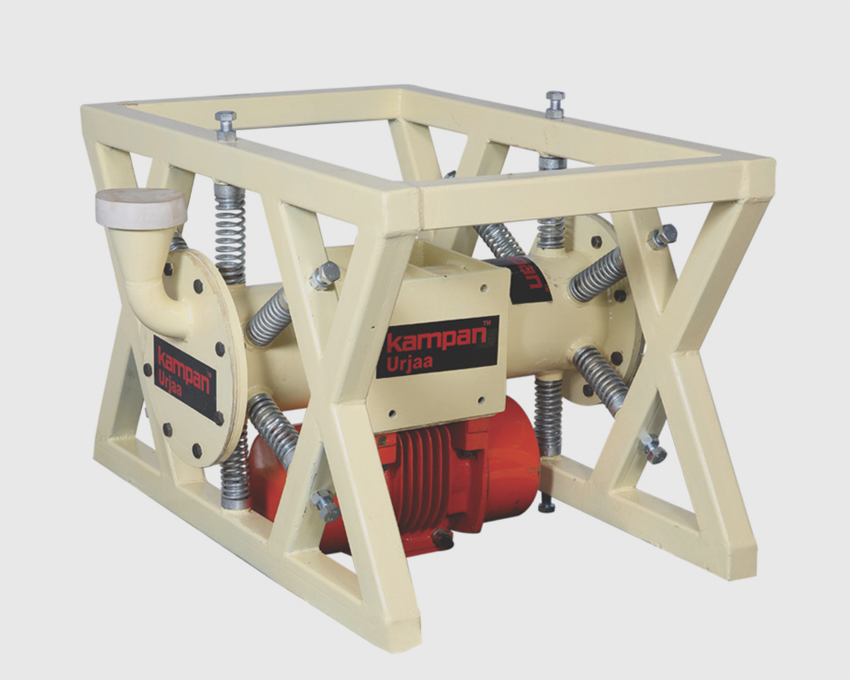

VIBRO ENERGY MILL

Particle reduction is the need of process industry since long. HVPL has engineered and developed innovative mill used for particle reduction using vibration technology, know as "VEM" (Vibro Energy Mill)

Various types of grinding mills are available in the market, vibratory grinding mills have been around from some time, but "VEM" is the unique design using vibration technology and major development in vibratory grinding.

Sizes available: VEM 1560, VEM 2510, VEM 4020 and VEM 7520

Features

- Extremely energy efficient

- Rapid grinding cycle

- Capable of ultrafine grinding to micron particle size

- Relatively small and lightweight

- Easily trailer or truck portable

- Minimum foundation required

- Very high impact forces generated for hard grinding

- Air swept option for air classification while grinding

- Dry grinding / milling OR Wet milling

- Low capital, installation and maintenance cost

- Mixes, blends and homogenizes during grinding

- Choice of grinding media - SS316 / SS304 / Hard sheet / Alumina

- Choice of liners - Urathane, Stainless steel, hard liner

How it works

'VEM' chamber is completely suspended / isolated using 'Tuned Springs' method. Drive is directly connected to the chamber. This unique design saves and reuses 'rebound' vibrational energy. Due to high speed of motor, action generated within grinding media inside chamber is exactly similar to traditional rotating ball mill, but with high attrition rate. 'VEM' is not limited by gravitation action falling ball method and generates very high impact forces over grinding media by rapid action of vibro motor, resulting in fine / ultrafine grinding.

Much larger and more frequent impacts on the material results to faster and fine grinding. The VEM mill is remarkably fast and energy efficient, and is capable of quickly reducing very hard material into micron level. No special foundation is required since the energy applied is directly back into the mill and not the floor.

HVPL designs and supplies complete grinding and sizing systems for all types of materials. Systems include precrushers, variable feed material feeders, conveyors, dust collectors and rotary valves. Special particle size equipment available includes: Standard Screen, Ultrasonic Screens and Adjustable air cyclone classifiers.

Application Industries

Alumina | Manure | Atomized Aluminum Powder | Metal Slag | Mica | Ash | Milkweed | Nickel | Bauxite | Oyster Shell | Barite | Pearlite | Black Sand | Pharmaceuticals | Boron Nitride | Pigments | Boric Oxide | Plastics | Bromine | Bronze | Polymers | Calcium | Quartz | Carbon | Ceramics | Clay | Char | Coal | Salt | Compost | Sand | Corn | Diamonds | Silica | Feldspar | Silica Slag | Silicon | Fiberglass | Sodium Benzoate | Fluorspar | Sulfur | Fly Ash | Talc | Fume Silica | Teflon | Graphite | Tile Scrap | Reclamation | Garnet | Titanium | Gold Ore | Tri-Calcium Phosphate | Gypsum | Vanadium | Hay | Hematite | Vermiculite | Herbs | Vitamins | Iron Oxide | Walnuts | Limestone | Magnetite | Magnesium | Zeolite | Manganese | Zircon