About Us

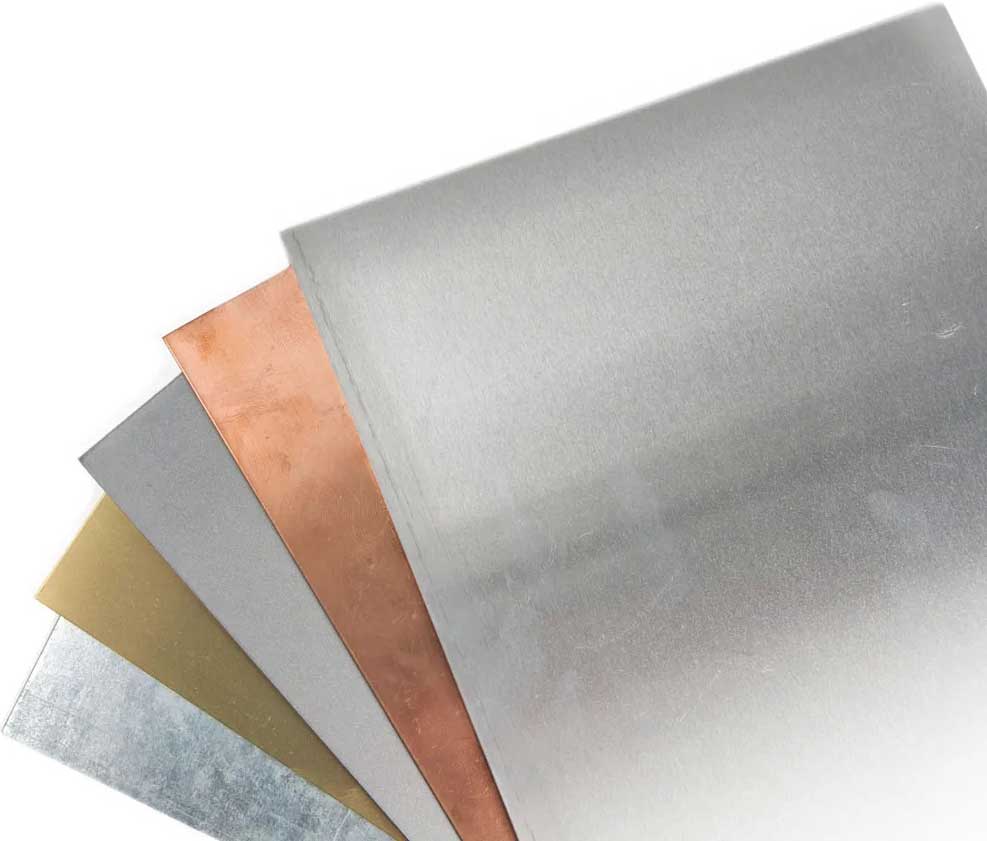

JAAS is a private limited company, engaged in Heavy Sheet Metal press parts manufacturing, severing for both automotive and off highway vehicles manufactures. JAAS was a initially set up in 2001, as a proprietary firm known as 'Annu Enterprises', engaged in Press Tool Design and Dies Manufacturing, with a capital of Rs. 0.15 million. Over the years, this Company has grown into an auto ancillary Company, manufacturing sheet metal components, sub-assemblies and heavy fabrication for reputed customers like ACGL, Thermax, KOEL, Gabriel and crossed a turnover of Rs 80 million in a span of last 10 years. To cater to the growing demand from our customers, we have expanded to two new manufacturing locations in quick succession. At chakan company has acquired 15000 Sq. ft. land and set up a new modern manufacturing facility on a built-up area of 1,20,00 sq. ft. This facility is incorporated as a private limited firm known as 'JAAS Automotive India Private Ltd'.