Safeguarding natural resources (like rivers, lakes, and more) is an important part of wastewater treatment solutions. Whether Industrial Waste Water or Sewage Treatment, as your business partner, Aquatic Solutions helps customers meet ever increasing environmental, regulatory, and financial pressures.

The purpose of wastewater treatment is generally to remove from the wastewater enough solids to permit the remainder to be discharged to receiving water without interfering with its best or proper use. The solids which are removed are primarily organic but may also include inorganic solids. Treatment must also be provided for the solids and liquids which are removed as sludge. Finally, treatment to control odors, to retard biological activity, or destroy pathogenic organisms may also be needed.

While the devices used in wastewater treatment are numerous and will probably combine physical, chemical and biological methods, they may all be generally grouped under six methods:

- Preliminary Treatment

- Secondary Treatment

- Sludge Treatment

- Primary Treatment

- Disinfection

- Tertiary Treatment

Degrees of treatment are sometimes indicated by use of the terms primary, secondary and tertiary treatment. Tertiary treatment, properly, would be any treatment added onto or following secondary treatment.

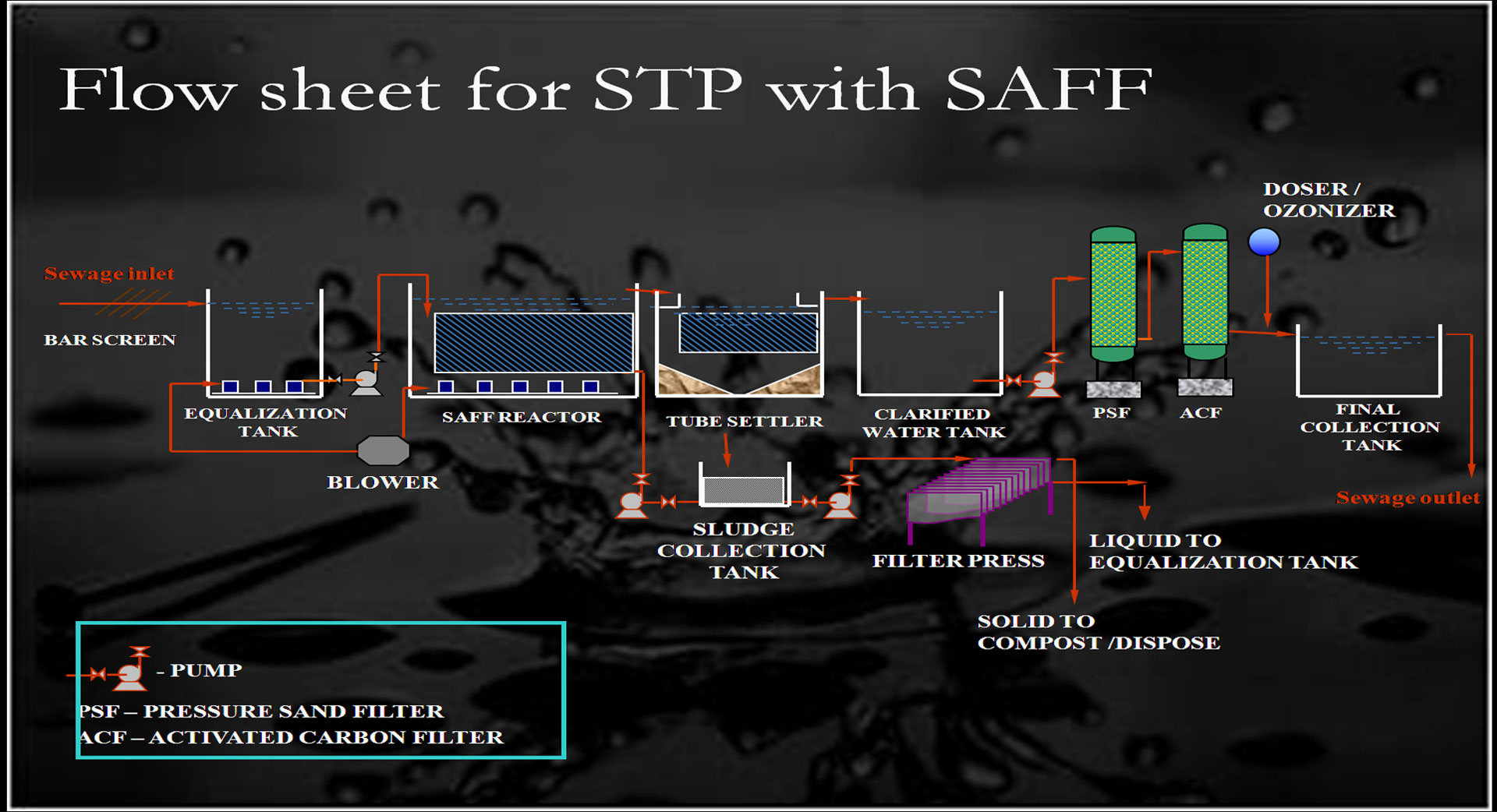

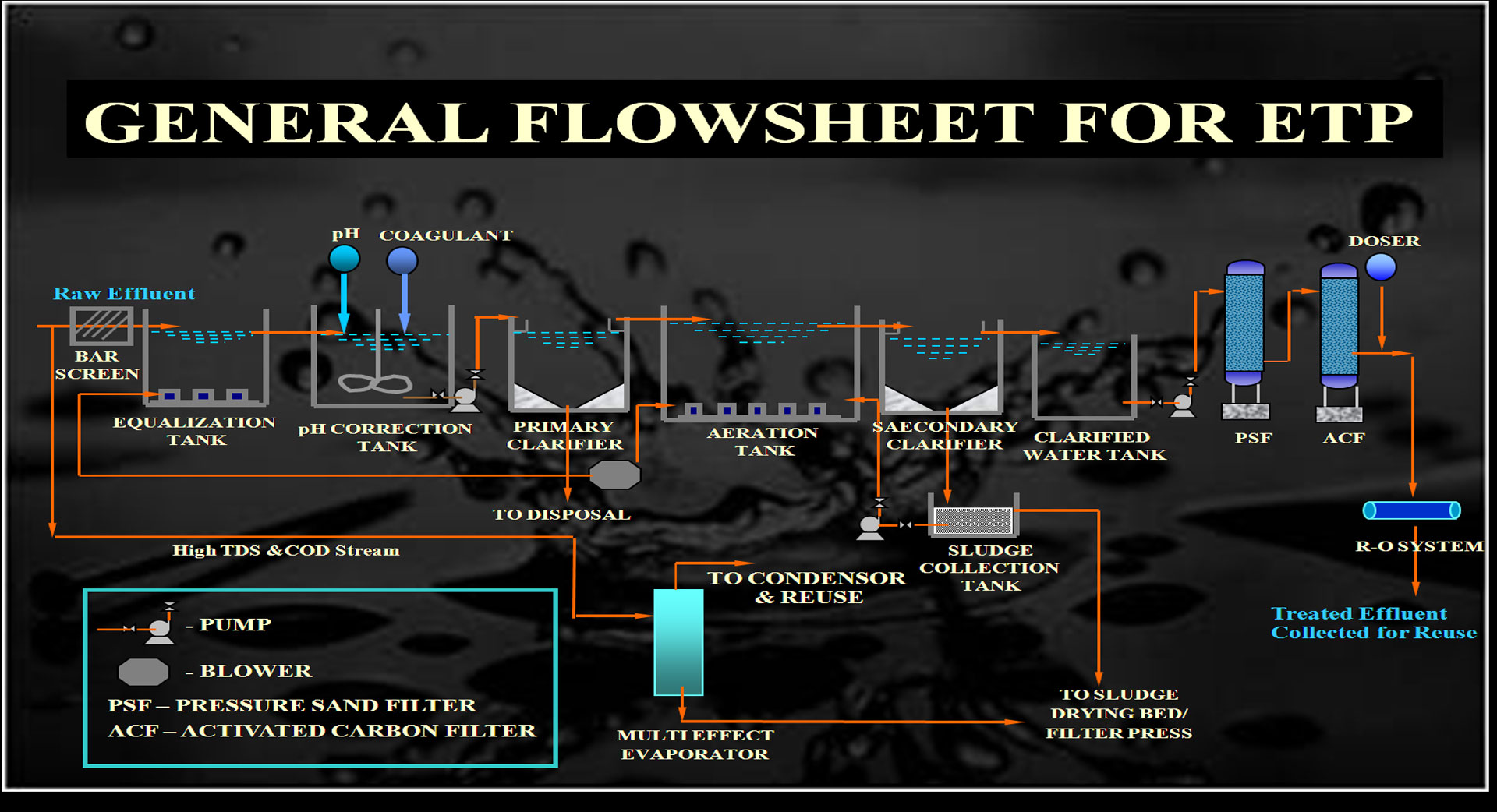

Preliminary Treatment

At most plants preliminary treatment is used to protect pumping equipment and facilitate subsequent treatment processes. Preliminary devices are designed to remove or cut up the larger suspended and floating solids, to remove the heavy inorganic solids, and to remove excessive amounts of oils or greases.

To effect the objectives of preliminary treatment, the following devices are commonly used:

- Screens -- rack, bar or fine

- Grit chambers

- Comminuting devices -- grinders, cutters, shredders

- Pre-aeration tanks

In addition to the above, chlorination may be used in preliminary treatment. Since chlorination may be used at all stages in treatment, it is considered to be a method by itself. Preliminary treatment devices require careful design and operation.

Primary Treatment

Variations in design, operation, and application, settling tanks can be divided into four general groups:

- Septic tanks

- Plain sedimentation tank with mechanical sludge removal

- Two story tanks -- In-house and several proprietary or patented units

- Upward flow clarifiers with mechanical sludge removal

When chemicals are used, other auxiliary units are employed. These are:

- Chemical feed units

- Flocculators

- Mixing devices

Secondary Treatment

In secondary treatment may be divided into four groups:

- Trickling filters with secondary settling tanks

- Intermittent sand filters

- Activated sludge and modifications with final settling tanks

- Stabilization ponds

Sludge Treatment

This is accomplished by a combination of two or more of the following methods:

- Thickening

- Drying on sand bed -- open or covered

- Elutriation

- Heat drying

- Wet oxidation

- Digestion with or without heat

- Conditioning with chemicals

- Vacuum filtration

- Incineration

- Centrifuging

Tertiary and Advanced Wastewater Treatment

Tertiary treatment has been used to describe processes which remove plant nutrients, primarily nitrogen and phosphorous, from wastewater

.

Improvement and upgrading of wastewater treatment units as well as the need to minimize environmental effects has led to the increased use of tertiary treatment.

A term that is also sometimes used to indicate treatment of a wastewater by methods other than primary or biological (secondary) treatment is advanced treatment. This degree of treatment is usually achieved by chemical (for example coagulation) methods as well as physical methods (flocculation, settling and activated carbon adsorption) to produce a high quality effluent water.

What this means for you

- Leverage a complete set of solutions (chemical, equipment, and services) from one provider

- Contribute to a sustainable water supply that reduces discharge by increasing reuse opportunities.

- Reduce energy consumption and footprint with innovative solutions.

- Treat and clean severely impaired water.

- Improves uptime while reducing maintenance time and costs

- Zero Liquid Discharge by Evaporation