Email id : info@duexin.in

Download Dehumidifier document

DUEX® dehumidifiers are fully self-contained, packaged units which incorporate an air circulation fan and an R-22 (Optional: totally CFC free) refrigeration circuit. The fan draws room air into the machine passing it firstly across a refrigerated heat exchanger (evaporator). This cools the air, causing the moisture in the air-stream to be precipitated onto the evaporator as water.

This Desiccant dehumidifier has all the features you would expect from a much larger model and all the maneuverability you would expect from a small model.

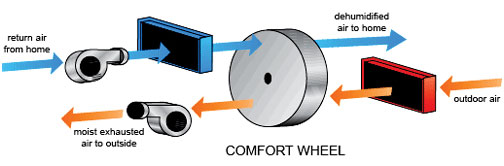

HOW IT WORKS:

The revolutionary new technology of DUEX DRIMOP® rotor is specifically designed to maximize moisture removal and achieving desired RH in Room Moisture from the return air is first dried by the evaporator coil and then is further dehumidified as it passes through the Comfort Wheel. The moisture-laden wheel then rotates into the outdoor air stream where the waste heat from the condenser coil heats the outdoor air so that it dries the wheel and discharges the unwanted excess moisture outdoors.

1) Desiccant Based System -

This is a combined desiccant with DX dehumidification. It is a highly efficient unit because it utilizes the waste heat from the condenser coil to regenerate the desiccant rotor providing further dehumidification. The unit has the ability to remove moisture efficiently. In addition, the unit does not increase the temperature of the supply air- it actually provides A/C tonnage.

2) Whole Room Dehumidifier -

This is typically installed in the room with its own separate return and supply. It can also tie into the existing air handling system and distribute dry air throughout the ductwork.

3) Simple Design-

This is a relatively simple piece of equipment. It consists of two blower fans, a rotating desiccant wheel, and a compressor with an evaporator and condenser. Periodic filter changes typical of any HVAC equipment is all that is required for maintenance. The “heart” of the unit, the desiccant wheel, should never need changing and will not lose its capacity over time and is designed to last the life of the equipment. The desiccant wheel carries a 5 year limited warranty (a 1 year limited warranty is offered on the rest of the equipment).

4) Simple Installation -

The unit is a self contained packaged unit. A return air line is connected to the unit and a supply line is branched to 2 or 3 registers throughout the room as per requirement through duct. Outdoor air is ducted to the unit through ducts to provide the regeneration air and exhaust air. The unit can also tie into the existing air handling system- it does need a separate return and a gravity flow damper on the supply to prevent back draft. For commercial installations, an outdoor unit is available if required.

5) High Moisture Capacity -

This unit is capable of controlling the humidity in a typical room / hall.

This is typically installed with its own return air and supply ducts. The supply air duct is branched to two or three supply air ducts servicing main rooms.

FLP versions available with certification

GMP versions available with DQ-IQ-PQ-OQ documentation

Features :

Portable Dehumidifier ( FLP / Non-FLP/ GMP versions available )

Model: Dew Point

Technology: AERO

Type: Refrigerant based

Orientation: Vertical

Industrial model: DPS/G FLP C/E

Flameproof model: DPS/G FLP C/E

DUEX design achieves upto 30% RH ( under controlled conditions )

Please find attached Selection Guide for selecting Dehumidifier model. Please note that this is just a gestimate and final selection depends on number of persons in room, humidity required, door openings per hour etc.

| Model X = S/G |

Max Area Covered | 0% RH Setting | Air Flow | Water at (30 C90%RH) |

Water Tank (LXWXH) Optional |

Overall Dimension (LXWXH) | Power Supply | Power | Wt (Max) |

| SFT | CMH | Ltr Per Day ( CC / hr ) |

MM ( Elite ) |

MM | V~ | Watts | Kg | ||

| DPX 3600 (ND 290) |

150 | HI - LO - MED | 150 | 14 (583) | 140X120X160 | 340X415X740 | 240V~ 1 ph |

250 | 29 |

| DPX 6000 (ND 318) |

250 | 33-99 | 180 | 30 (1250) | 160X100X125 | 375X415X800 | 240V~ 1 ph |

350 | 55 |

| DPX 8000 (ND 390-i) |

350 | 30-99 | 220 | 40 (1666) | 160X100X125 | 440X550X905 | 240V~ 1 ph |

500 | 71 |

| DPXB 12000 (DH 504) |

500 | 30-99 | 480 | 60 (2500) | 305X215X1135 | 480X550X1980 | 240V~ 1 ph |

750 | 79 |

| DPXB 18000 (DH 702) |

750 | 30-99 | 850 | 75 (3124) | 305X215X1135 | 635X605X1195 | 240V~ 1 ph |

1000 | 102 |

| DPXB 24000 (DH 902) |

1000 | 30-99 | 1100 | 99 (4124) | 305X215X1135 | 635X605X1170 | 240V~ 1 ph |

1500 | 124 |

| DPXB 36000 | 1500 | 30-99 | 1700 | 158 (6583) | No water tank [ Hose connection provided ] |

635X605X1170 | 415V~ 3 ph |

2500 | 1500 |

| DPXB 48000 | 2000 | 30-99 | 2200 | 198 (8249) | 635X605X1170 | 415V~ 3 ph |

3500 | - | |

| DPXB 60000 | 3000 | 30-99 | 3000 | 260 (10833) | 700X600X12000 | 415V~ 3 ph |

5000 | - | |

| DPXB 96000 | - | 30-99 | - | 20 Ltr / Hr | 700X600X12000 | 415V~ 3 ph |

5000 | - | |

| DPXB 144000 | - | 30-99 | - | 30 Ltr / Hr | 700X600X12000 | 415V~ 3 ph |

10000 | - | |

| X in model denotes S= Standard G= GMP; B= High Static | |||||||||