Manufacturing Facilities

Starting with a small fabrication unit at MIDC Bhosari in 1992, today Fabtech group has five manufacturing units in Pune with advanced manufacturing facilities for manufacturing of heavy pressure vessels, heat exchangers, columns, reactors, etc. in carbon steel, stainless steel, alloy steel & other exotic materials. In addition, we are developing a new facility spread over 15 acres (6,00,000 sq. Feet) of land in the MIDC Industrial area (Phase II) at Chakan.

Certifications & Approvals

Our shops are approved by engineering consultants & various reputed customers including EIL, PDIL, Toyo, UHDE, Jacobs, KPG etc.

We have PESO approval for manufacturing of mobile & storage vessels for LPG & related materials; we also have IBR shop approval.

Our shops are ASME “U”, “U2”, “S”, “NB”, “R” stamp certified.

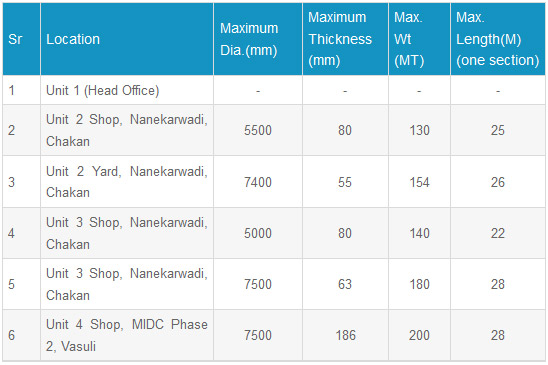

Fabtech's manufacturing facilities with capacities (Total capacity- 7000 Tons/ Annum)

- Total covered area of manufacturing units : 80,000 sq. ft. (2 Acres)

- Total open area for manufacturing : 1,20,000 sq. ft. (3 Acres)

- Total area under sister concerns : 3,00,000 sq. ft. (7.5 Acres)

- Total area under development: 6,00,000 sq. ft. ( 15 Acres)

Capabilities

The scale and diversity of our services require strong engineering capabilities. Our manufacturing units have the expert personnel and the infrastructure required for every phase of the manufacturing cycle:

- Covered shops

- Bending facilities

- Handling facilities (EOT and mobile cranes)

- Heavy press machines

- Automatic and manual welding machines

- Drilling facilities

- Qualified and experienced team for production and quality control in shops

- Qualified and experienced team for handling projects from office as well as site

- Equipment/Tools/Tackles for project execution

- Streamlined processes enabled by SAP ERP system.

Capabilities - Highlights

Bending:Our new manufacturing unit is equipped with the state-of-the-art bending machine manufactured by Davi, Italy. The machine can cold roll up to 186 mm thick x 3 meters wide carbon steel plates.

Drilling:

We have installed a European make Vertical CNC drilling machine (Arboga, Sweden) which can drill with L by D ratio of 15 without any angular deviation up to a diameter of 2,000 mm in a single setup. We are also installing Dayoung make horizontal deep hole drilling machine which can drill in 20 mm diameter up to lengths of 1,000 mm.

Welding:

With the dedicated efforts of our R & D team, we have automated the welding techniques such as zero gap weld by SAW process, overlay on smallest inside diameter of 45 mm, thin wire overlay on various materials for cladded equipment and strip cladding. Our welding team has developed welding techniques for exotic materials, ferritic and austenitic stainless steels.

In-house Modular Furnace:

With our in-house Modular Furnace (size 10 meters x 10 meters x 27.5 meters) we can carry out heat treatment for all the equipment we manufacture.

In-house Testing Facilities:

Our comprehensive testing facilities include:

- Hydro testing

- Radiography testing

- Magnetic particle testing

- Thickness testing

- Hardness testing

- Pneumatic testing

- Ultrasonic testing

- Dye Penetrant testing

- Elcometers

- Profile gauge

Home

Home