Our Products

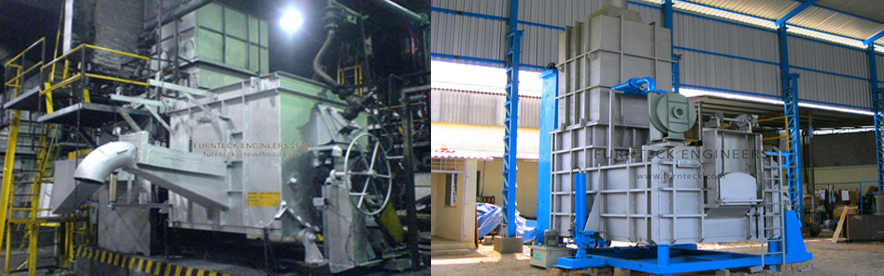

ECOMELT-EMT - Electromech Tilting Tower Melting Furnaces

The high degree of automation, quality of the materials and simple construction of the equipment guarantees a reliable and efficient production with high degree of economy resulting in profitable production of molten metal.

The high degree of automation, quality of the materials and simple construction of the equipment guarantees a reliable and efficient production with high degree of economy resulting in profitable production of molten metal.

Fields of application

♦ Central melting in Die casting

♦ Ingot manufacturing

♦ Alloy making

♦ Metal recycling

♦ Bulk melting

General Performance Specs

Fuel Consumption - 650KWH/ton at 720deg

Metal loss - < 1%

Capacity - 300kg/hr to 6 Ton/Hr

Loading - By Auto charger

Fuel - LDO/FO/HSD/LPG/Propane.

ECOMELT-EMT consists of

♦ Stationary melting chamber

♦ Electromechanical tilting holding chamber connected to melting chamber by a tunnel

♦ Auto charger

Advantages

♦ Minimum oil consumption.

♦ Low melting losses

♦ Low risk of hydrogen absorption.

♦ Easy wall to wall access for through cleaning.

♦ Minimum man power requirement. ( Only 2 nos )

♦ Low operating cost.

♦ Continuous supply of molten metal.

♦ Capacity range – 300Kg/hr to 4000Kg/hr

The high degree of automation, quality of the materials and simple construction of the equipment guarantees a reliable and efficient production with high degree of economy resulting in profitable production of molten metal.