- Dust Collection Systems

- Belt Conveyor

- Bucket Elevator

- Screw Conveyor

- Rotary Airlock Valves

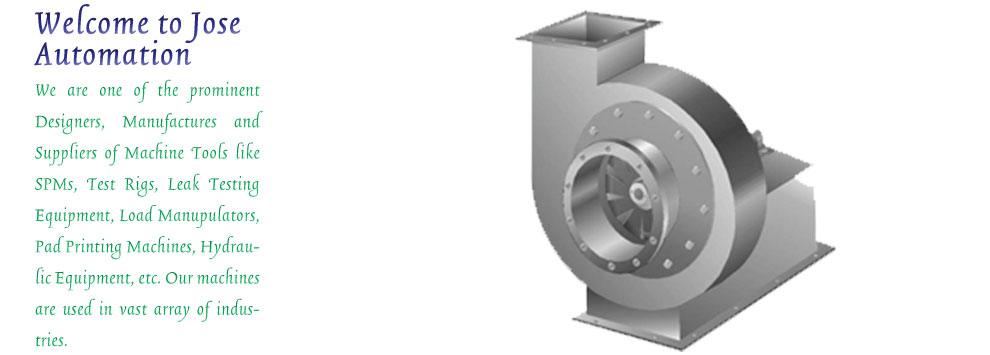

- Centrifugal Fan

- Slide Gate

Office :- Flat No.10,

Sidhaai Appartment,

Near RTO Office, Poorna Nagar,Chinchwad,

Puneľ 411019.

Works : -Gate.No12,

S block, 116,

Swami Samarth industrial Co.

Op.Society, MIDC Bhosari,

Near Enviro Electro Dine

pune-411026.

Web site-

www.jkautomationpune.com

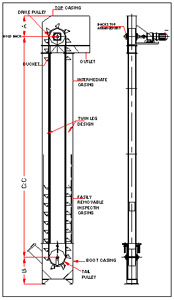

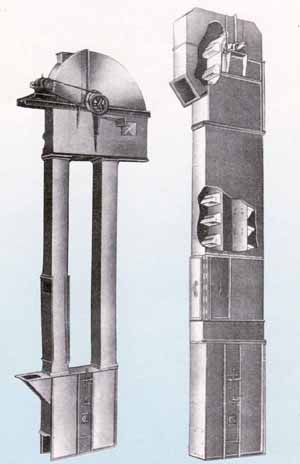

A bucket elevator can elevate a variety of bulk materials from light to heavy and from fine to large lumps

It consists of:

1. Buckets to contain the material;

2. A belt to carry the buckets and transmit the pull;

3. Means to drive the belt;

4. Accessories for loading the buckets or picking up the material, for receiving the discharged material, for maintaining the belt tension and for enclosing and protecting the elevator.

A centrifugal discharge elevator may be vertical or inclined. Vertical elevators depend entirely on the action of centrifugal force to get the material into the discharge chute and must be run at speeds relatively high. Inclined elevators with buckets spaced apart or set close together may have the discharge chute set partly under the head pulley. Since they don't depend entirely on the centrifugal force to put the material into the chute, the speed may be relatively lower.

Nearly all centrifugal discharge elevators have spaced buckets with rounded bottoms. They pick up their load from a boot, a pit, or a pile of material at the foot pulley.

The buckets can be also triangular in cross section and set close to on the belt with little or no clearance between them. This is a continuous bucket elevator. Its main use is to carry difficult materials at slow speed.

Early bucket elevators used a flat chain with small, steel buckets attached every few inches. Current construction uses a rubber belt with plastic buckets. Pulleys several feet in diameter are used at the top and bottom. The top pulley is driven by an electric motor.

Some of the salient features of our Bucket Elevator system comprises of the following:

- High performance

- Corrosion resistance

- Durability

- Consumes less floor space

- CE Marked Components and Entire System

Bucket Elevators represent one of the most popular systems in use today for elevating bulk materials. Their inherent simplicity makes them a popular choice for bulk material handling and processing applications all over the world. Continuous developments in bucket shape, head and boot profiles, manufacturing and operating specifications have resulted in the highly efficient Elevator range available today.

Specification

In general most free flowing materials and many materials with poor flow characteristics can be successfully handled with a bucket elevator. The rate at which material can be elevated depends on many factors in addition to the obvious effects of bucket design, capacity and speed. In particular attention has to be paid to material charge and discharge characteristics.