WORKING PROCEDURE

We believe in the quality work & for the same we adopt the following procedure for all jobs.

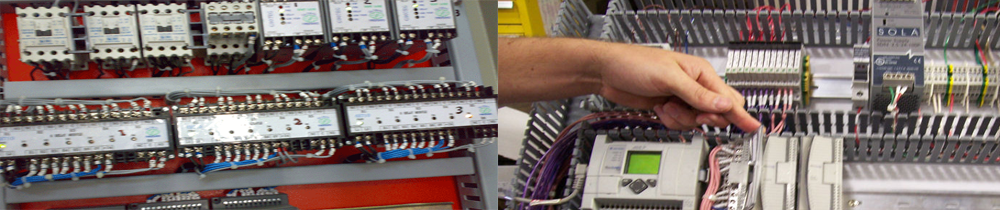

After receiving firm order we make designs of cubicles and actual Electrical Circuits. After receiving approval from client actual manufacturing is initiated.

Firstly as per our design we get the cubicle fabricated & painted or powder coated as per the customer’s requirement from our vendor and then actual assembly work is done. After assembly and wiring every panel is tested as per the design and functional requirement. During this method 3 stage inspection is done. Every panel undergoes these inspections i.e. after fabrication, painting and final assembly & wiring.

After our final inspection we call our client’s representative and the panel is inspected once again and then it is dispatched.

This 3-stage inspection method helps us to improve our quality and we can certainly satisfy our client’s requirement by delivering Quality products.

DESIGN PROCEDURE

We consider the following procedure for designing control panels

• Aesthetically good design

• Functionally easy for operation

• Robust & sturdy mechanical design

• Use of standard codes for wiring and identification of components

• Compact design without compromising Quality

• Switch Gear & Bus Bar rating as per universal standards

• Make of Components as per clients recommendation

• Drawings are drafted using German based Eplan software.