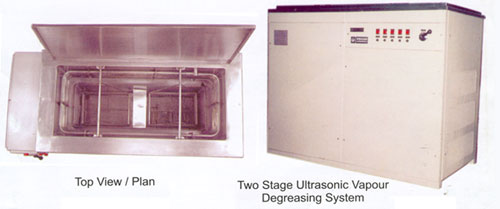

Multi Chamber Vapour Degreaser

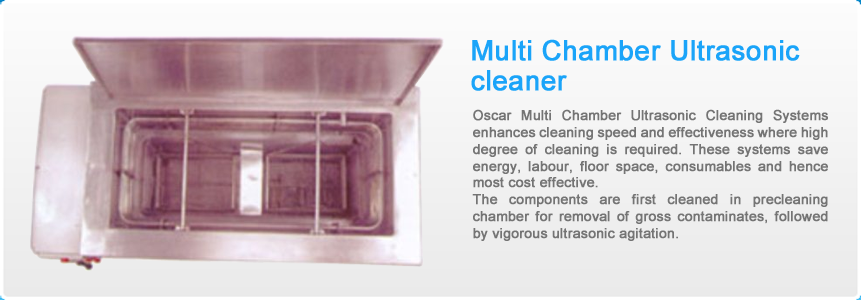

Oscar Ultrasonic Vapour Degreasing System enhances cleaning speed and effectiveness where high degree of cleaning is required. These systems save energy, labour, floor space, consumables and hence most cost effective.

Oscar Ultrasonic Vapour Degreasing System enhances cleaning speed and effectiveness where high degree of cleaning is required. These systems save energy, labour, floor space, consumables and hence most cost effective.

How does it work ?

The components are first cleaned in pre cleaning chamber for removal of gross contaminates, followed by vigorous ultrasonic agitation. Then the components are held in vapour chamber for vapour condensation to remove the residual contamination. As the components reach the vapour temperature the condensation stops and components come out clean and dry. For efficient solvent recovery, water is circulated in the condensing coils. The system comprises of two, three or four chambers depending upon the level of contamination and degree of cleaning required. Units are also available with direct refrigeration cooling systems, distillation plants, filtration plants and fume extraction systems.

- Multi Stage Ultrasonic Vapour Degreasing System : Oscar Ultrasonic Vapour Degreasing Systems come with elegantly painted, compact, portable cabinets and are ideal for following applications :

- General Industries : Tools, dies, moulds, castings, gear, mechanism, pumps, bearings, spray guns, vacuum valves, fire extinguishers, cutlery, scissors, silverware, brassware. LPG valves & components etc.

- Electronics : Semiconductor components, PCB's, Electronic assemblies, Capacitors, Rotary Switches, Resistors, Electronic Microscope Components, Cathod Ray Tube Components, Solar Cells.

- Electricals : Motors, Generators, Supply Meters, Voltmeters, Ammeters, Switches, Thermostats, Switch Gears, Vacuum Interrupters, Circuit Breakers, etc.

- Aircraft : Bearings, Pumps, Filters, Hydraulic Components, Altimeters, Anemometers, Gyroscopes.

- Automotive : Fuel Injectors, Spark Plugs (Carburetors), Pistons, Valves, Bearings, Filters, Engine Blocks, Shock Absorbers.

TECHNICAL SPECIFICATIONS FOR 2 CHAMBER VAPOUR DEGREASING SYSTEM

| UVD / 2/ 250 | UVD / 2/ 500 | UVD / 2/ 750 | UVD / 2/ 1000 | ||

| Chamber Dimensions Effective (mm) |

U/S Chamber

Vapour Chamber |

300 x 250 x 125

300 x 250 x 125 |

400 x 300 x 200

400 x 300 x 200 |

500 x 350 x 200

500 x 350 x 200 |

600 x 400 x 300

600 x 400 x 300 |

| Overall / Outer Dimensions (mm); |

900 x 550 x 950 | 1550 x 620 x 1100 | 1750 x 620 x 1100 | 1750 x 700 x 1400 | |

| Total Solvent Cap. (Lit) | 18 | 48 | 70 | 144 | |

| U/s Power Output | 250 W | 500 W | 750 W | 1000 W |

| Input Voltage | 230 V, 1 Ph / 50 Hz OR 415 V, 3 Ph 50 Hz with four wires |

TECHNICAL SPECIFICATIONS FOR 3 CHAMBER VAPOUR DEGREASING SYSTEM

| UVD / 3/ 250 | UVD / 3/ 500 | UVD / 3/ 750 | UVD / 3/ 1000 | ||

| Chamber Dimensions Effective (mm) |

Pre. Cleaning Ch

U/S Chamber Vapour Chamber |

300 x 250 x 125

300 x 250 x 125 300 x 250 x 125 |

400 x 300 x 200

400 x 300 x 200 400 x 300 x 200 |

500 x 350 x 200

500 x 350 x 200 500 x 350 x 200 |

600 x 400 x 300

600 x 400 x 300 600 x 400 x 300 |

| Overall / Outer Dimensions (mm); |

1300 x 550 x 975 | 2050 x 620 x 1125 | 2350 x 670 x 1125 | 2650 x 700 x 1400 | |

| Total Solvent Cap. (Lit) | 27 | 72 | 105 | 216 | |

| U/s Power Output | 250 W | 500 W | 750 W | 1000 W |

| Input Voltage | 440 V, 3 Ph / 50 Hz with four wires |