Manufacturers and suppliers of conveyor.

We offer nylon fabricated conveyor belting system, designed to provide high speed, long life and better performance in terms of cost per tonnage of material it convey. Our Constructional Features:

• Higher Tensile Strength:

We offer an advanced strength, nylon fabricated belts that has rationalize the traditional cotton belts. Our two piles of nylon fabric are equal to the strength of five piles of cotton fabric.

• Higher Adhesion:

Due to the chemical bonding between cover to ply and ply to ply, our adhesion to nylon conveyor belting system, is double to that of conventional cotton belts

• Complete Rot Resistance:

Our conveyor belt has eradicated the problem fabric deterioration, where we use wet material.

• Reduced Belt Weight::

Our nylon conveyor belts are is to handle as they are lighter than the equivalent all-cotton belts due to reduced piles and lower weight.

• Straight Ply Construction:

Our nylon fabricated belts are laid straight extending across the width of the belt.

• Stepped Ply Construction:

Our conveyor belts are cushioned with extra rubber cover to fill the missing gaps in first and second plies to improve transverse flexibility.

• Reverse Stepped Ply Construction:

It is the reverse of one stepped ply construction, where missing gaps in first and second plies are filled with rubber to improve the flexibility. These belts are designed with waterlogged ash handling installation in boiler plants that operate under water. The specifications of rubber cover used in belt are:

• Thickness at the bottom 3.05/ 5.0 mm

• Thickness at the top at 1.5/ 2.0 mm

• Heat resistant cover grade used is 4/2

• H-Tex cover grades used is 5/3

• Reversed stepped plies equal to 6/4

• Breaker Ply Construction:

To protect against the longitudinal impact of breaks, we have laid "leno weave" breaker cords diagonally across the belt. The breaker fabrics are also used in pairs where they are laid on opposing 450 angles for extra severe impact protection. Further we also offer proceed breaker, which are used for adding 1mm thickness to the belt.

• Skim-coated Plies:

For improving additional interaction between the piles, we provide extra thickness to our rubber coating by inserting heat impact cushion. In case of cut in our rubber we provide scan quote service to our clients

• Edge Construction:

We offer nylon fabricated conveyor belting system in cut and molded edge, as they are rot resistance to guard against edge wearing. Our belts are sharply molded to avoid the entrance of moisture in the corner of the belt, to protect against it we are adding to it 1200 mm rubber cover. We manufacture our wide range of rubber cover using finest quality input carcass or Nylon / Nylon (NN) Carcass. The salient features of carcass include:

• Lower longitudinal elongation

• Higher tensile strength

• Good Flexibility and trough ability

• Good resistance to edge wears

• Good resistance to milde.

Belt designation (Nylon/Nylon) |

Maximum Recommended Working tension (vulcanised splice) |

Nominal carcass thickness |

Nominal carcass weight |

Max. belt width (mm) for satisfactory load support material density (T/m3) |

Min. belt width (mm) for satisfactory troughing |

Type Rating |

KN/m |

(mm) |

(Kg/nf) |

Upto 1.0 |

Upto 1.5 |

Upto 2.5 |

20° |

30° |

45° |

101 |

20 |

2.3 |

2.6 |

650 |

500 |

400 |

Our chain conveyor uses many types of interleaving segment to form a chain of either synthetic polymer or steel. These conveyors allow frictionless transportation of goods and offer high impact resistance. Our conveyors are generally used in high wear areas that generally deal with handling of individual packet or can filling or bottling operations.

These conveyors are mostly used in food and pharmaceutical industries and can be washed down for hygiene reasons.

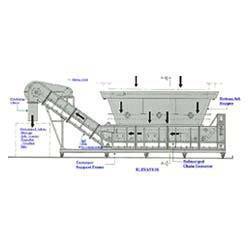

Our wet scrapper conveyors are used for one or more sliding chains in a trough with the material. They are suitable for conveying material that are free flowing granular or lumpy. They can also handle wet and moderate sticky material. The low profile scrapers provide a small area for material to cling to. Some material commonly conveyed include bagasse, calcined coke, clay dirt, coal, fly ash and slag. It has extremely low-maintenance and can be mounted as single or interlinked conveyor .

This is known for high wear resistance due to sandwich bottom and high stability due to special design of the conveying tub.

Our corporate commitment to our customers around the world is clearly demonstrated by an investment of over $5 million in our state-of -the-art Worldwide Conveyor Belting Technical Center in Marysviile, Ohio, USA. Using the advanced facilities and equipment at its disposal, our research and development team keeps us at the leading edge of conveyor belting technology. We leverage all our expertise in rubber and reinforcement technology to provide our customers with conveyor belting that delivers lowest cost per tonne of material conveyed.

Our Top of the Line Technology helps produce Bottom Line Profits for you

Goodyear Conveyor belts are designed from the inside out to our specifications to endure the everyday abuse of tonnes of coal,aggregate, wood and hard rock to name a few.

Goodyear Product Range covers Grades:

Type – M24

Type – HRT1

Type – HRT2

Goodyear Conveyor belting is also available in Oil Resistance, Super Abrasion Resistance, Chemical Resistance Cover Grades.