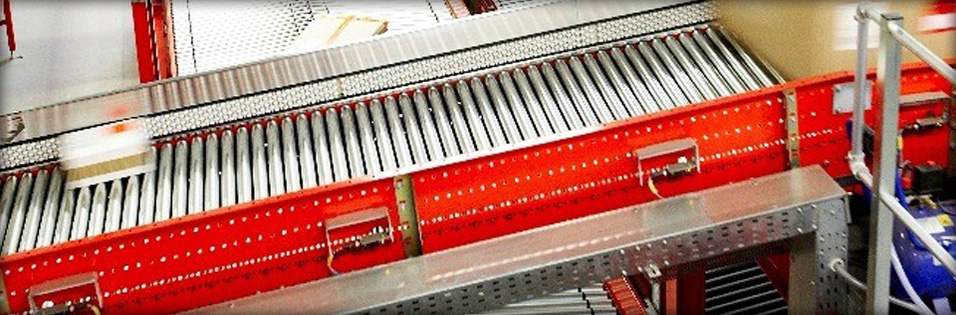

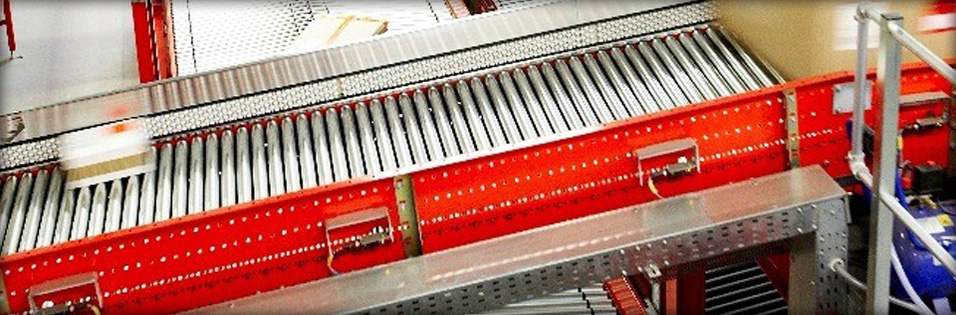

Piku Industries was incorporated in the year 1995. We are a multi disciplinary engineering company with a range of specialist operating in material Handling systems. Our multi disciplinary approach to meeting clients need is a key point of differentiation in highly competitive market. Driven by Technology, We leverage on our experience and expertise to set benchmarks and retain competitive edge. Located in Indore, We have proved our excellence through our wide gamut of high performing equipments and our ability to take turnkey projects. We undertake turnkey. Consultancy, manufacturing & installations of material Handling systems viz. Belt conveyors, screw conveyors, Drag chain conveyers, bucket elevators etc. • In addition we have expertise ourself in doing various plants of coal handling systems, Stone crushing & screening plants, coal washeries etc. Our highly experienced engineers are giving engineering solutions encompassps all critical elements using in house exprtise.

Business Type

Year of Establishment

Annual Turnover

Total Number of Employees

Supplier

Manufacturer

1989

Upto US$ 0.25 Million (or upto Rs. 1 Crore Approx.)

Upto 10 People

Optimal & Judicious Utilisation of Vital Resources - Time, Man, Money, Material, Machine & Energy.

In Conjunction with Advanced Techique,Logical Approach & Efficient Teamworks.

Further Catalyzed by: the will to Achieve, the Confidence to succeed & unstaken belief in Almighty to globally realise our ultimate goal "total technological satisfaction"

that is what the abbreviation "TTS" STANDS FOR

Our advanced infrastructure set up and use of modern technology has enables us to produce functionally superior testing equipment as per the customized requirement of our clients. In order to serve to the needs of our clients, we produce conveyor belts, rubber conveyor belts, chain conveyors, screw conveyor, wet scrapper conveyor, special purpose conveyor belts, belt conveyor pulleys, belt conveyor rollers, belt conveyor idlers, belt conveyor systems, special application belts, bucket elevators, MS grating tray, MS cable tray, vibro AVM pads, track shoe pads and conveyor accessories

All these machines exhibit the following salient features:

Auto detection of overload

Ability to withstand voltage fluctuations

Accurate readings

Robust construction

Compact design

Better efficiency

Stable metallurgical properties

Less power consuming

Easy maintenance

Further, we provide customization facility for our entire range of conveyor belts, to achieve optimum satisfaction of our clients.

Owing to our vast industrial experience, we are able to manufacture high grade conveyor belts and accessories. Our products being technically advanced and use of finest quality raw material enhance the life of our range. These are available at affordable prices and cater to the needs of a number of industries which include:

Agriculture industry

Cement industry

Construction Industry

Engineering industry

Automobile industry

Our manufacturing unit, which is spread over an area of 37000sq.feet and is equipped with latest and high the machines, which have an installed capacity of 500 Sets, with our factory located in Sanwer Road Industrial Area, Indore (M.P.).

Moreover, we follow a systematic and well developed manufacturing process, whereby particular attention is paid on the quality of the raw material used so as to ensure that the final produce is flawless.

Our modern and sophisticated facilities are competently handled by our workforce so that we can easily achieve our target production and fulfill the bulk demands of our clients on time. Some of the machines and facilities available at our unit are as follows:

Hydraulic Power Press Machine

Hand Press Machine

Buffing Motors

Generator

Compressor

Lathe Machine

Sharper Machine

Welding Machine

MIG Weld Machine

Bandsaw Machine

Measuring Instruments

In addition to the above mentioned facilities, we also have an in-house design wing that is operational with latest design tools including CAD/CAM basic software. This facilitates us to design the blueprint of rubber components with a view that our designed component are up to the mark of technical and dimensional specifications. Further, we have incorporated latesttechnological method in manufacturing conveyor belts up to 1200 mm width accurately to the specifi requirement of our customer.

Our team is the biggest asset of our company and our constant support system. We have qualified and talented professionals from varied fields, who work in coordination to ensure that our entire tasks are executed in a qualitative and fruitful manner. Our team of technical experts, mechanical and processing engineers, rubber technologists and other technicians are engaged in designing innovative and custom-made conveyor belt and accessories. Along with our quality controllers and R&D experts they make sure that the component are designed efficiently so that they operate effectively and offers enduring performance.

Our diligent sales and marketing executives work hard to make sure that we are never out of order and this is evident from our ever-rising sales figures. Being a vital part of our organization our team is the real factor behind our exemplary success in the rubber component industry.

We have the most upgraded technology to meet the need and expectations of our customers in the field of designing

Our strengths that have enabled us to carve a niche in the global market are as follows:

Qualitative spares

Timely delivery

Excellent packaging facilities

Precision engineered

Economical prices

Flexibility to offer customized specifications

Easy payment options

In order to keep ourselves ahead of our competitors, we are always engrossed in finding new methodologies to produce most advanced and innovative products range that includes all features and properties desired by our clients. For this we have invested in a full fledged research and development wing that is handled by our experienced R&D personnel.

They make judicious usage of our resources and various print and electronic medium to gather information about latest advancements in the rubber conveyor belts and to conduct their study and research work. Based on the results & conclusions of their study and the inputs provided by our clients, they devise latest designing and production methodologies so as to fabricate technologically advanced rubber conveyor belts and accessories.

Warehouse is important part of our organization, which assist us in storing our entire range to prevent them from any damage. We have a voluminous warehouse with a capacity of 25000 units, which has all the required facilities that it must have such as forklifts and cranes which are used to load and unload our product. We have a systematic storage system and large storage capacity, which enables us to access the required product easily.

Further, to ensure the original condition of our conveyor belts our packing personnel make use of quality material such as LDPE/HMHDPE and others. The goods are delivered to the customer in the estimated time of 15 days. In addition, we also pack our products as per our customers’ specifications.

Over the years, we have served a long list of clients who are scattered around the country and further look forward to think and act according to the requirements of our clients. This enables us to conceive products that are economically advantageous and make a significant contribution in the industry. For the convenience of our clients, we provide them various options for making payment such as money transfer through bank, cash, letter of credit, demand draft and e-payment.

We have an adroit team of quality assurance experts who ascertain that every stage of the production process is monitored vigilantly so as to keep up the quality consistent. Several parameters on which we check our range of products includes the following:

Capacity

Tensile strength

Resistance to corrosion

Resistance to extreme temperature conditions

Abrasion resistance

In addition to this, the company constant updating of Technology and enduring R&D Effort, we aim to exceed the expectations of our customers in term of quality, so that our clients do not face any inconvenience. Our quality analysts closely check the products on their quality standards on global scale so as to assure only quality proven goods reach our clients.

Backed by Highly experienced team of engineers, We are able to offer world class Fabrication & erection services for a wide range of material handling equipment. CVer the years. We have undertaken various industrial projects and have successfuly cornrrissioned them.