Resin Coated Sand Manufacturers

Precoated Sand Manufacturers In India

Resin Coated Sand is widely used in foundries using shell moulding process. We cater customers specific requirements like HSLD, BLG, Chromite, Ceramic Sand and Quartz Sand. Resin Coated Sand is manufactured by coating washed and graded dried sand grains with phenol formaldehyde resin liquid and Hexamine hardener with lubricants by warm coating process. We use Specialized Design Mixer for the manufacture with the use of state of the art technology. Use of high quality infrastructure with the latest technology is the main reason why we have maintained the consistency in quality of our product

Benefits Of Resin Coated Sand

- Castings can be produced with close tolerance and with very minimum machining allowances along with excellent surface finish.

- Self life of the resin coated sand is unlimited.

- Hollow cores can be produced.

- Lump free sand.

- No crack of core or shell.

- High transverse strength.

- Low density of Raysons Resin Coated Sand gives maximum output.

- Less core weight.

- Release agent gives maximum output without breakages.

- Fast curing of Raysons Resin Coated Sand gives high production with uniform baking of sand.

- Special fine Resin Coated Sand doesn't require refractory coatings or core paint, achieves better surface finish.

- Low rate of gas generation.

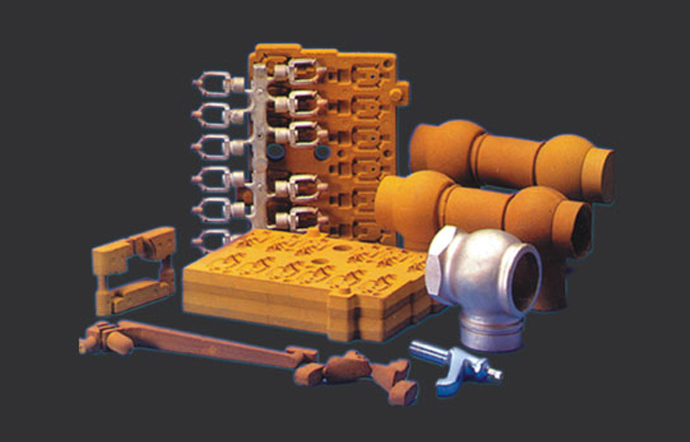

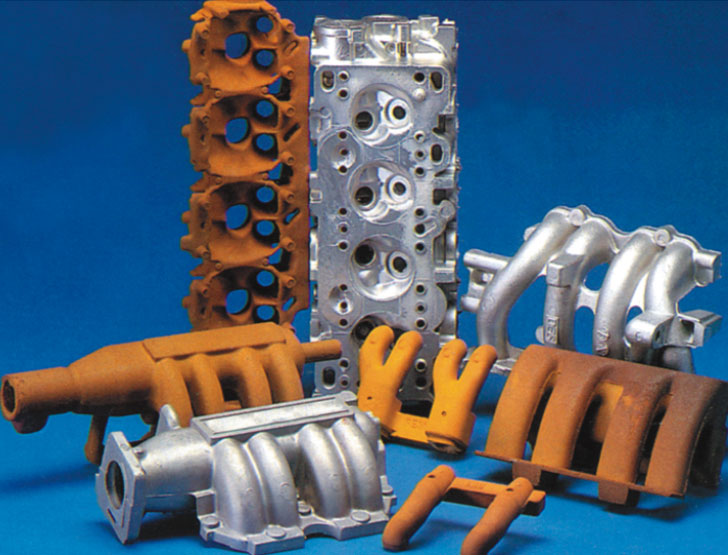

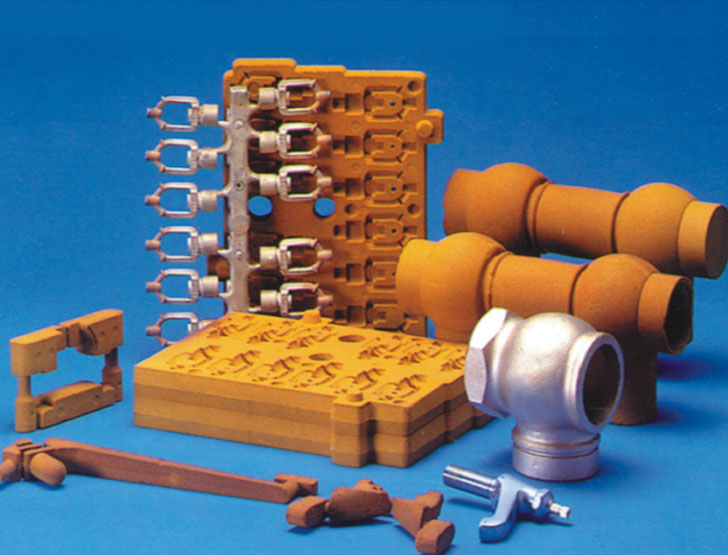

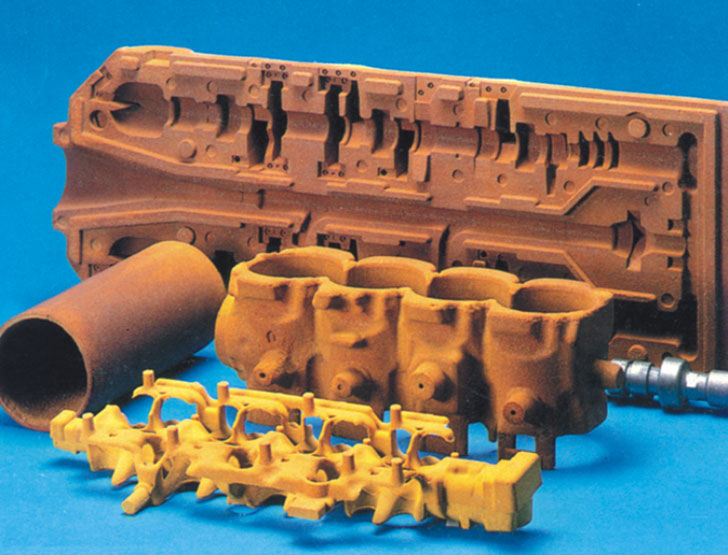

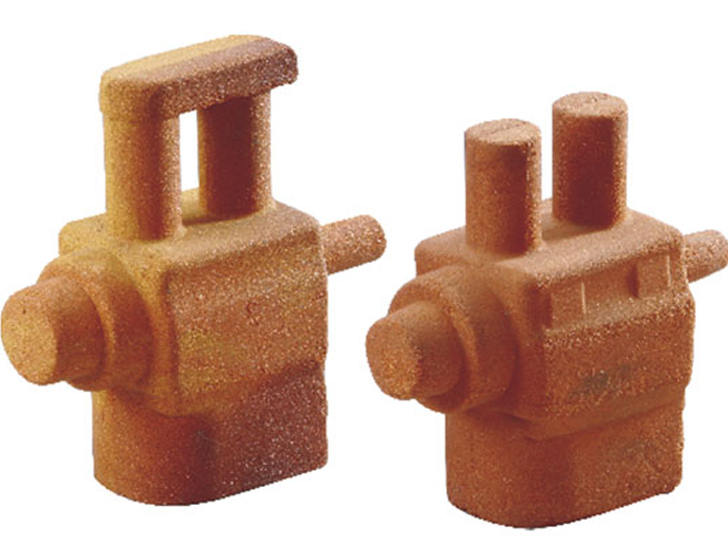

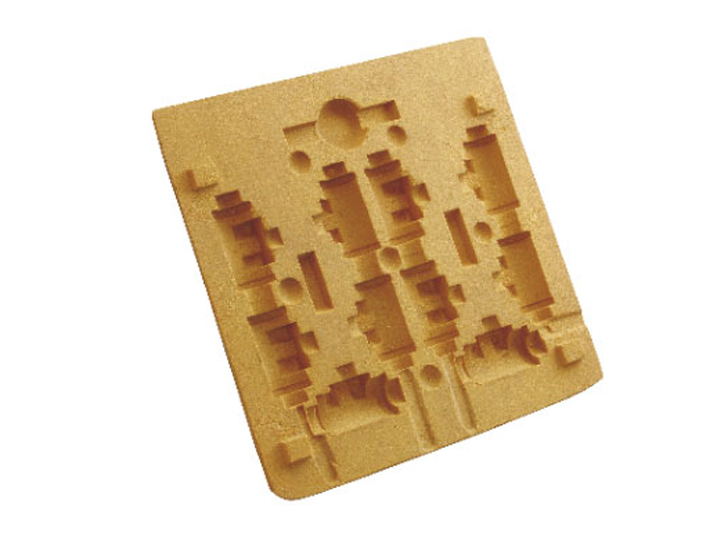

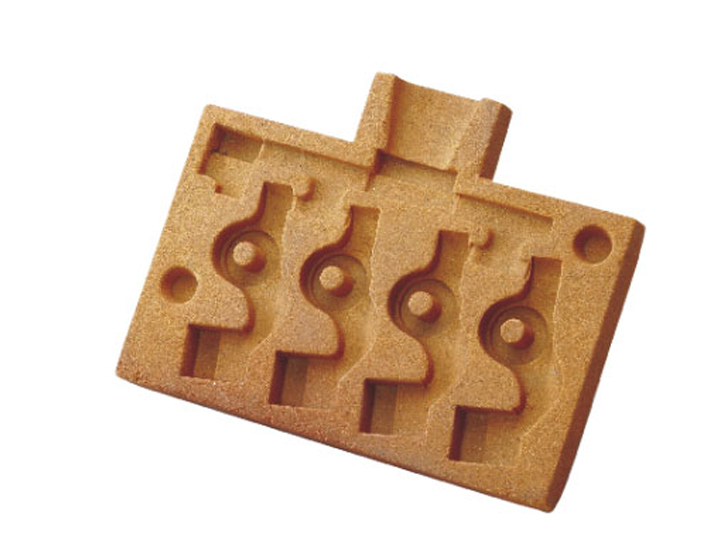

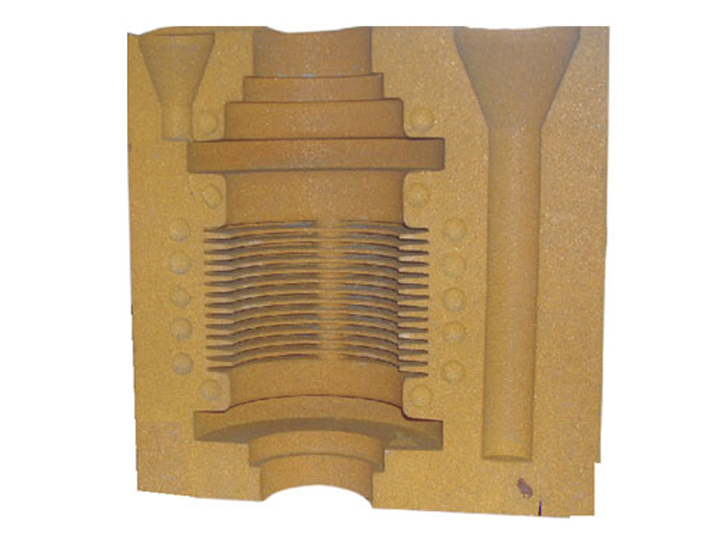

Gallery

Specialization

Raysons have developed a tailor made product to suit to exact customer needs. Raysons sand grades include Low Gas Sand, High Permeability, Collapsibility Sands.

Special offerings of Raysons Resin Coated Sand

- Easy decoring without thermal process for critical aluminum components.

- Improved release.

- Greater depth of cure.

- Uniform wall thickness.

- High curing speed.

- Faster build up rates.

- Special sand for aluminum and light alloy applications.

- Sand developed to minimize shake out time.

- Collapsibility rates are nearly twice as fast as normal coated sand.

Quality Assurance

We at Raysons have developed full fledged Quality Control Department to test all the critial and important parameters of resin coated sand as well as of the raw materials used.

Machine

- HTS Machine.

- CTS Attachment.

- AFS Machine.

- Transverse Strength.

- Gas Apparatus.

- MUFFLE FURNACE.

- Peel Back Machine.

- Stick Point Tester

- Sand Washer

To Check

- HTS of Resin Coated Sand.

- CTS of Resin Coated Sand.

- Mesh Size of Sand.

- Anti-Binding Strength.

- Gas Content.

- Loss 0n Ignition.

- Drop Off And Built Up.

- Stick Point of Sand.

- Clay Content of Raw Sand

Quality System

Raysons have developed a tailor made product to suit to exact customer needs. Raysons sand grades include Low Gas Sand, High Permeability, Collapsibility Sands.

Special offerings of Raysons Resin Coated Sand

- Raysons Industries has been awarded ISO 9002 certification by Standards Australia in February 1996.

- Subsequently both manufacturing units have been accredited ISO 9002 and have adopted quality systems since then.

- It is India's first RESIN COATED SAND manufacturer to get ISO 9002 from QAS, Australia.

- Ever growing customer base with number of reputed customers numbered more than 200.

- Our policy is to manufacture top quality product and ultimate customer satisfaction is our main objective and goal.

Capacity

We at Raysons have developed full fledged Quality Control Department to test all the critial and important parameters of resin coated sand as well as of the raw materials used.

- Raysons group is equipped with fully automatic sand processing and coating facility that can produce 40000 MT of RAYSONS RESIN COATED SAND per annum.

- Presently we manufacture 3000 MT per month of Resin Coated Sand.