Aluminium Extrusion

Process at S.V.

Extrusion is among the most widely used of the aluminum forming processes;The process begins with the creation of a metal die that precisely matches the profile of the shape specified by the designer. Aluminum billets or logs, produced from ingots, are heated and forced under pressure through the die. The variety of shapes that are possible is virtually limitless. Profiles are produced to exact specifications, with very close tolerances.

The most important factor to remember in the extrusion process is temperature. Temperature is most critical because it gives aluminum its desired characteristics such as hardness and finish.

The process begins with the creation of a metal die that precisely matches the profile of the shape specified by the designer. Aluminum billets or logs, produced from ingots, are heated and forced under pressure through the die. The process is quite similar to squeezing toothpaste from a tube. The variety of shapes that are possible is virtually limitless. What's more, profiles are produced to exact specifications, with very close tolerances.

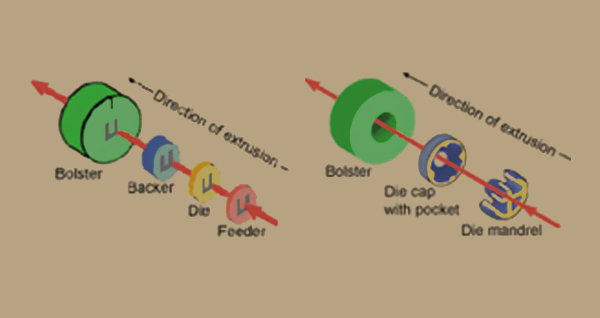

Tool Stack

(Die Assembly):-Solid: die ring, die, backer, bolster, and sub-bolster

Hollow:-

die ring, die mandrel, die cap, bolster, sub-bolster .

In order to help us understand your needs and requirements and service you better, the following is a check list of things to consider when submitting items to an extruder for quoting or new business:

- 1. Description or drawings of the part- Discuss and share your application early before the design is finalized.

- 2. Specifications to be met; as per IS or other standards.

- 3. Alloy and temper; if unknown, indicate requirements for strength, corrosion resistance, machinability, finish, weldability, to help the extruder in making a recommendation.

- 4. End use length and purchase length. (Normally in range of 1 Meter to 6 Meter)

- 5. Tolerances; As per standard/as per application.

- 6. Surface Finish; mill finish, , exposed surfaces, anodize/powder coating etc.

- 7. Packaging; acceptable maximum and minimum weight per package and shipping and handling requirements.

- 8. Product end-use.

- 9. Quantity needed; this order on monthly basis/annual basis.

- 10. Delivery date : Tentative date with development / ready dies.

- 11. Special quality considerations. QAP or any special format to be filled by QA.