Looks newer for longer

Launched in 1976, ZINCALUME® steel, the world's leading Al-Zn alloy coated steel product is an outcome of extensive research and continues to set standards for corrosion resistance and long life. It is designed to withstand the rigors of various climatic conditions, and for over two decades, the product's performance has been constantly monitored across a wide range of climatic conditions using exposure test sites and infield inspections.

ZINCALUME® steel

Cross Section

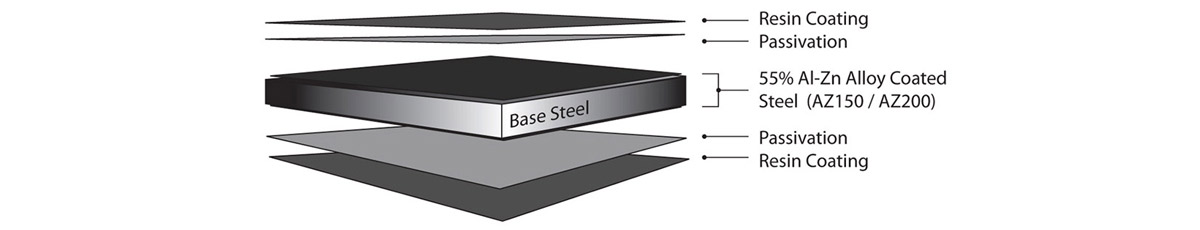

ZINCALUME® steel has 150 g/m2 or 200 g/m2 metallic coating distributed equally on both surfaces. It is available in Base Metal Thickness (BMT) ranging between 0.30mm to 1.30mm and coil widths of 900 to 1250 mm. It is offered with yield strength of minimum 300 MPa to minimum 550 MPa depending on the application. ZINCALUME® steel complies with AS1397, ASTM A792M, IS 15961 and ISO 9364 standards

ZINCALUME® Advantage

7 good reasons to believe in ZINCALUME® steel

ZINCALUME® Value Proposition

ZINCALUME ® steel is a zinc/aluminium alloy coated steel with a distinctive clear resin surface finish, made by Tata BlueScope, specifically for Light Gauge Steel framing system market. Wall and roof frames made from ZINCALUME ® steel are termite and fire resistant, straight and true, light-weight yet strong. Today, frames made from ZINCALUME ® steel are quick and simple to erect, easy on the environment, and adaptable to a myriad of building designs. Wall and roof framing made from ZINCALUME ® steel is 100% termite and borer proof. It is also non-combustible, which significantly reduces the amount of flammable material. Wall and roof frames made from ZINCALUME ® steel are precision engineered to be dimensionally accurate so that it reduces the problems such as cracking cornices, jamming doors, sticking windows or wavy rooflines. Besides, it lends itself perfectly to innovative designs and non-conventional roof lines, helping to create distinctive, highly individualized buildings. In particular, the high strength-to-weight ratio of steel roof framing allows for longer spans, creating larger, more open living areas. And because it's steel, it measures up against increasingly stringent building and fire regulations.

The thermal insulation for piping, especially in the processing industry, plays a vital role. It is highly imperative to maintain the required temperatures of fluids or gases. In applications like hot or cold insulation (e.g. turbines, boilers, pressure vessels, chemical processes in refineries, pharma and metallurgical industries and critical cryogenic processes), a properly designed 'Insulation System' enables achieving targets set through energy conservation.

The Preferred Material

ZINCLAUME® steel is a preferred material for pipe cladding due to its excellent impact resistance, higher strength, flexibility and excellent corrosion-resistance. It is also an economical solution for certain applications. The 55 per cent aluminum-zinc alloy coating provides both, long-term corrosion resistance of aluminum along with the galvanic protection of zinc at scratches and cut edges. ZINCLAUME® steel jacketing has a substantially longer life when compared with regular galvanised steel in marine and industrial atmospheres. At the same time, it provides superior fire-resistance and protection compared to aluminum. The special alloy coating of aluminum and zinc combines the best properties of both metals.

Superior Quality door / window frames can be made from ZINCALUME® steel and COLORBOND® steel. It provides immaculate strength along with excellent corrosion resistance without any warp or termite & thus improves life by several years. Properties which make it an excellent preposition in this application are: 1. High Corrosion Resistance 2. Termite Proof 3. Guaranteed Material Strength (Dimensionally stable) 4. Low Wastage 5. Saves time & money during painting, as no primer required & can directly have top coat 6. Non Combustible

The high strength and longevity of Tata BlueScope Steel provides the best value preposition for customers looking for an ideal solution for rolling shutters application. The features when clubbed with corrosion resistance and the aesthetic appeal becomes a more compelling value preposition for customers looking for a hassle-free long lasting solution.

The light weight of the drywall partition material combined with ease & simplicity of construction, makes drywall system a preferred solution in the Industry. ZINCALUME® steel with it's strength & lightweight becomes the first choice for steel stud frames which binds the gypsum / fiber cement boards. ZINCALUME® steel helps fabricate light gauge frames which in turn reduces the overall weight of partitions & drywalls and thus reduce the cost of installation and transportation.

Solar modules stand in very challenging environmental conditions for years & therefore the solar industry demands for high corrosion resistance material. ZINCALUME ® steel satisfies the solar application requirement & plays a critical role towards increasing the life of the system. Due to Excellent weatherability, ZINCALUME® steel gives an extra edge of up to 4 times life to critical parts of support system. HR sections & reduce overall weight of structure which in turn reduces the transportation cost & makes installation easier. It inturn reduces the maintenance and replacement cost.

ZINCALUME® steel is one of the world's leading Al-Zn alloy coated steel ideal for roofing, wall cladding and manufacturing alternate applications. Metallic coating of ZINCALUME® steel combines the corrosion protection of aluminium with sacrificial protection of zinc that enhances corrosion resistance and gives significantly longer service life than the galvanized coating. ZINCALUME® steel is manufactured using proven technology and durable surface treatment (coated with special passivation and resin as a separate layer) ensures your roof and wall cladding looks newer for a longer period of time.