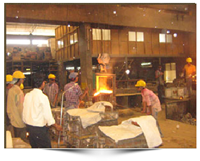

Facilities - Melting & Pouring

We have two introduction furnace of capacity 300 kg and 500kg.

Make:- Electrotherm, Ahmadabad, India.

Melting charge is prepared as per requirement of material grade by customer.

Work instructions for melting process and addition of Ferro alloys, Runner/ Riser etc. is displayed on sight near furnace. Spectro analysis of each heat is done by melting supervisor in two stages.

1) Bath Analysis after about 85% melting Completion.

2) Final Analysis before pouring.

Temperature Checking is done by Calibrated temperature indiactor. Pouring temp. for different grades is mentioned in quality plan.